Electric kettle with modified temperature control device

A technology of an electric kettle and a temperature control device, which is applied in the field of electrical appliances, can solve problems such as short service life, unsafe use, and the water level cannot be too high, and achieve the effects of ensuring sensitivity and safe use, simple appearance, and clean use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

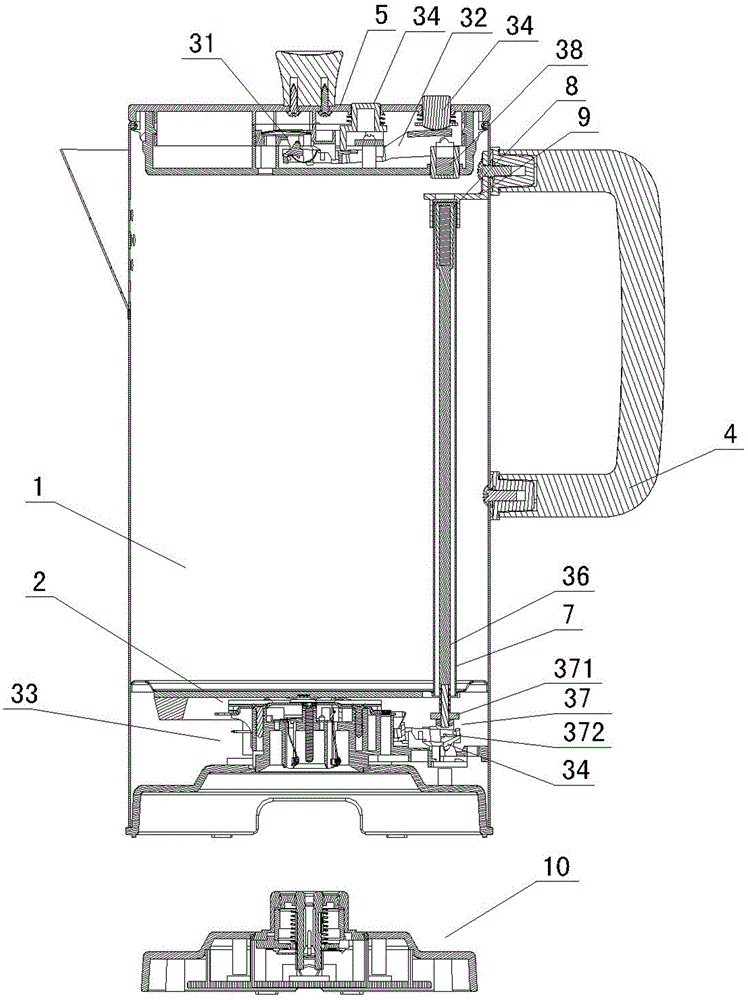

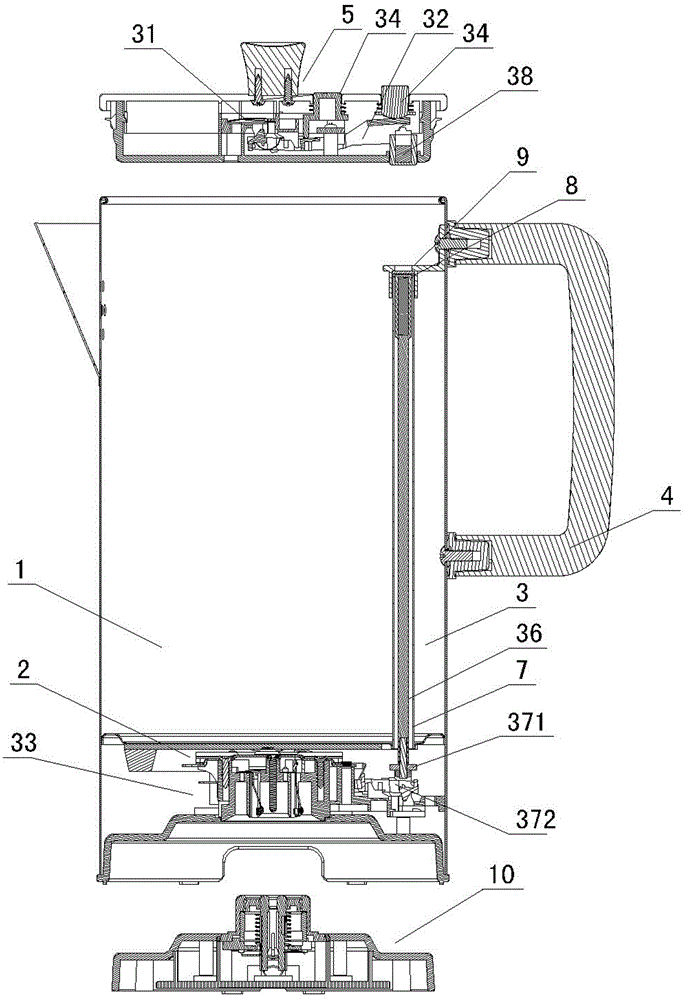

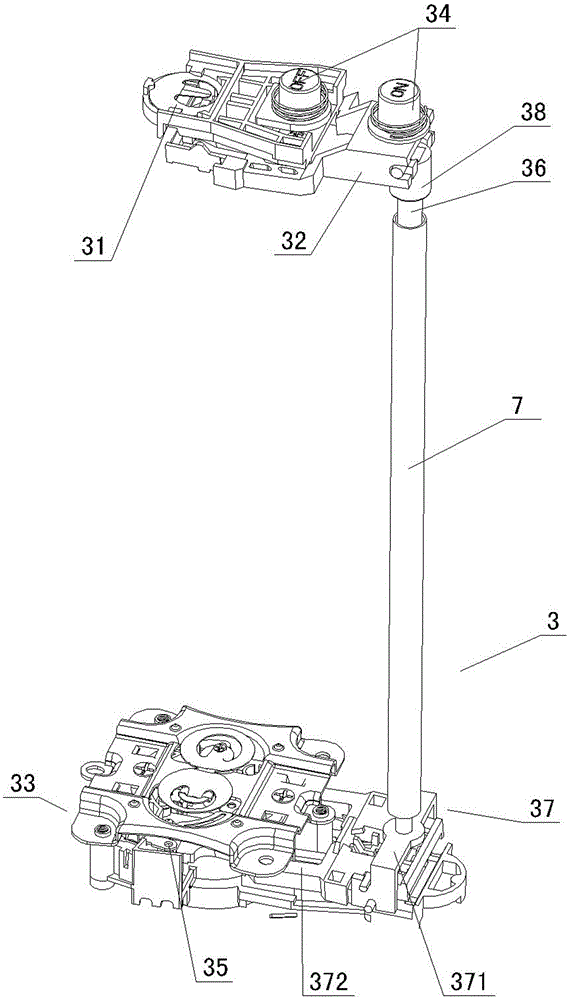

[0019] Such as Figure 1-Figure 4As shown, the electric kettle with the improved temperature control device of the present invention includes a kettle body 1, a heating device 2, a temperature control device 3 connected to the heating device 2, and a power base 10. In order to make the present invention not only safe to use, Can make the electronic element of temperature control device 3 effectively moisture-proof again, described temperature control device 3 comprises the temperature sensor 31 that is installed in kettle steam area, the power switch part that is connected with heating device 2, temperature controller 33 and connects described sensor. The mechanical transmission device 32 of thermostat 31 and power switch part, and described power switch part comprises the switch button 34 that is connected with mechanical transmission device 32, the electronic component power switch 35 that is connected with switch button 34 and thermostat 33, and described A gas barrier seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com