Wavefront sensor with variable shear rate based on random coded mixed grating

A technology of wavefront sensors and hybrid gratings, applied in instruments, scientific instruments, measuring optics, etc., can solve problems such as the limitation of the diversity of detection objects, and achieve the effects of simple and flexible adjustment devices, flexible and flexible measurement, and strong generalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

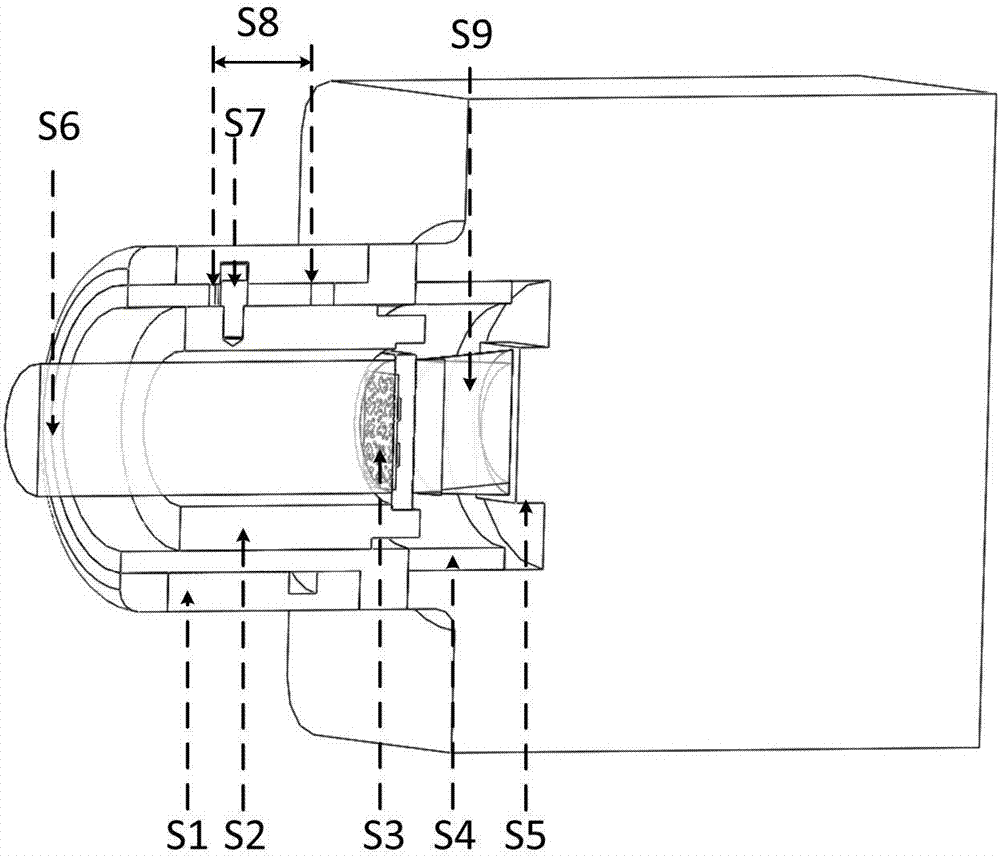

[0032] An example of the wavefront sensor of the present invention based on a random coded hybrid grating variable shear rate is described as follows.

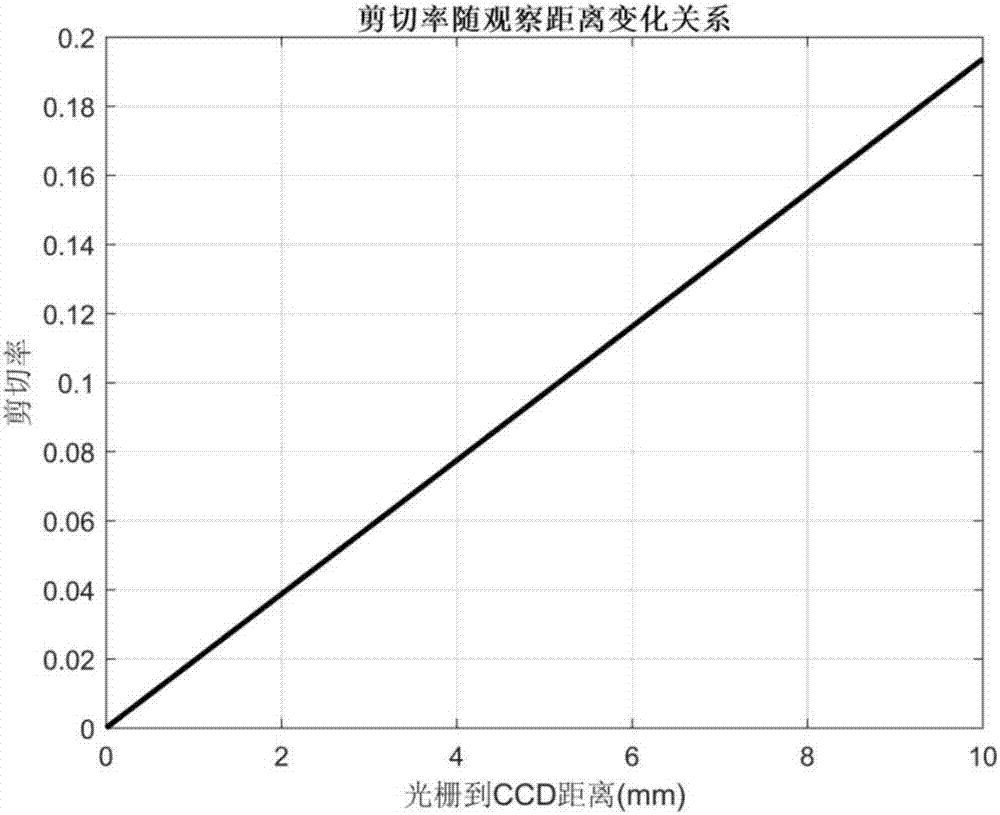

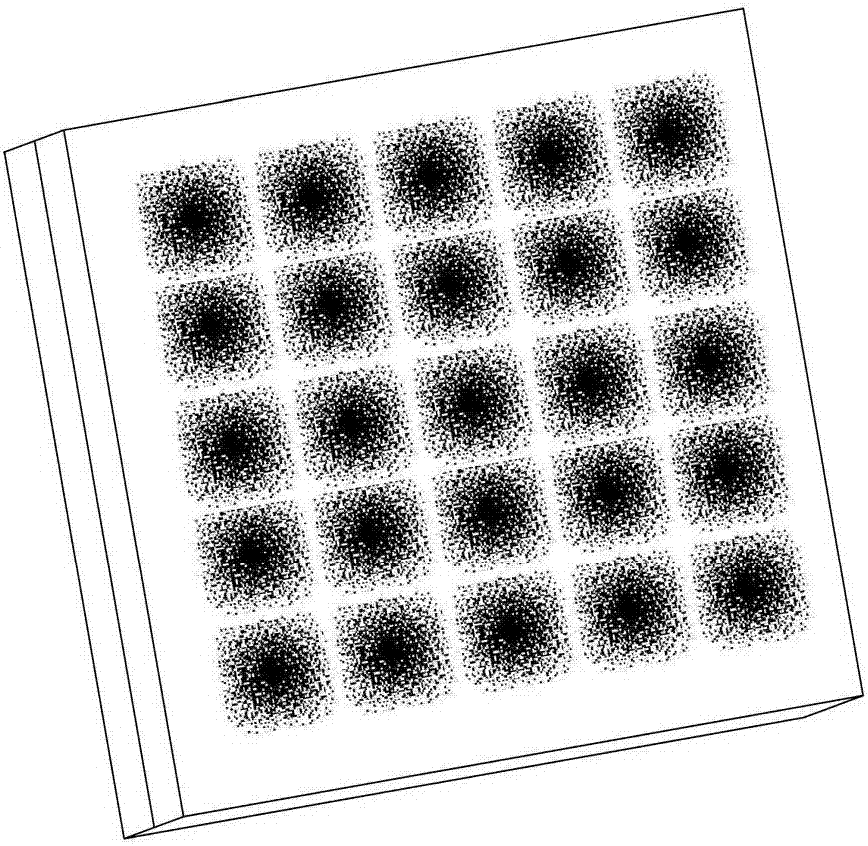

[0033] For wavefront sensors with variable shear rates based on randomly coded hybrid gratings, different shear rates are required for wavefronts with different distortions to take into account both accuracy and sensitivity. For waves with large PV (Peak-to-Valley) A small shear rate is required to ensure accuracy, and a large shear rate can be appropriately selected to increase sensitivity for a wavefront with a small PV value. like Figure 9 Shown is the relationship between the detection error and the shear rate of the large distortion wavefront (PV=7.2603λ, RMS=1.7222λ). It can be seen that when the shear rate is greater than 0.1, the error increases. is so large that the sampling law cannot be satisfied. On the contrary as Figure 10 Shown is the relationship between detection error and shear rate of small distortion w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com