A device and method for fine cleaning of photovoltaic components in large photovoltaic power stations

A photovoltaic module and photovoltaic power station technology, which is applied in photovoltaic power generation, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of increasing power station operation and maintenance costs, damage to photovoltaic module sealing materials, and increased water and labor costs. Achieve the effect of being conducive to precise management, shortening cleaning time, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

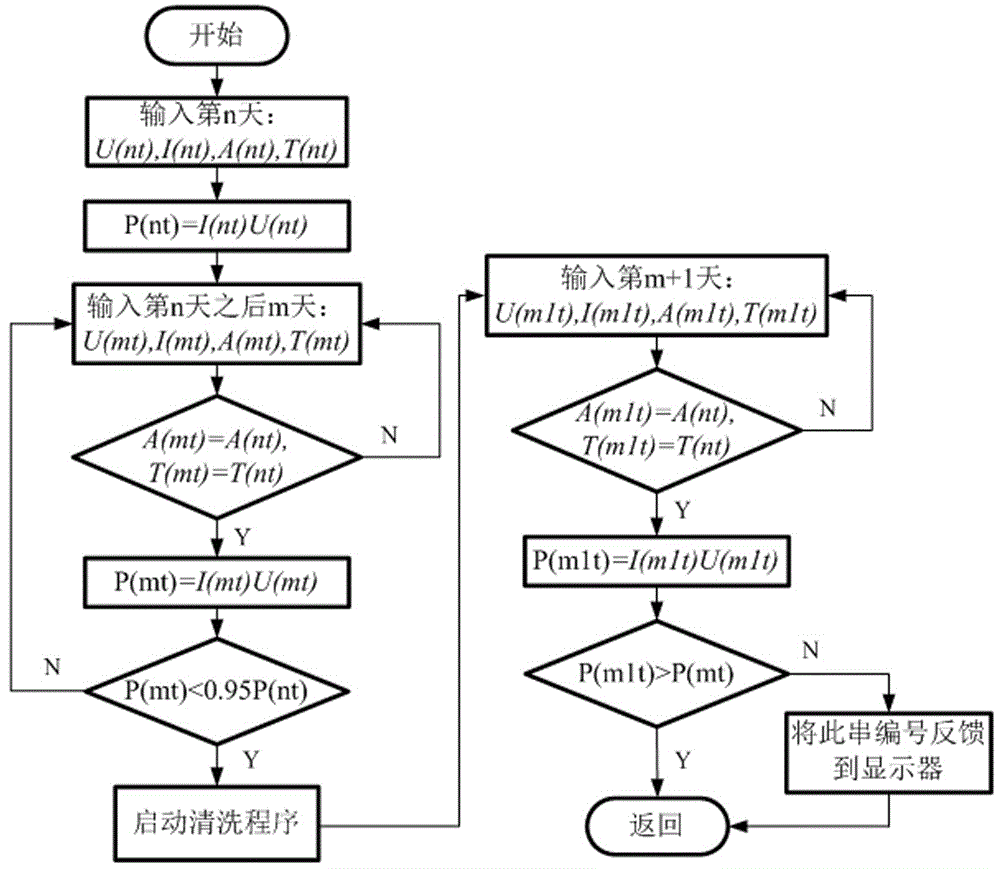

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

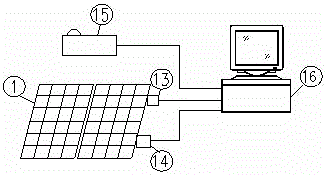

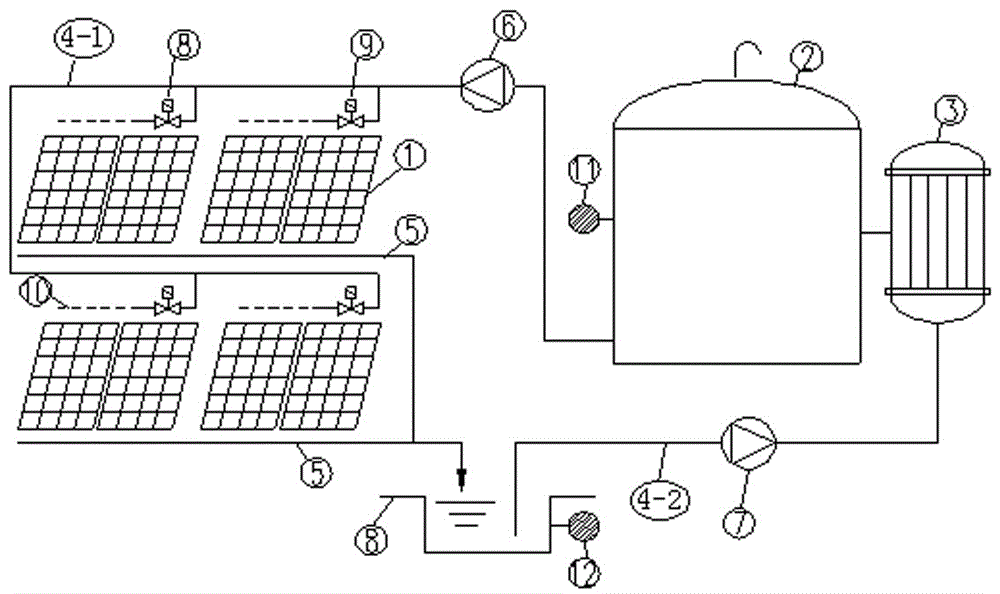

[0035] refer to figure 1 , figure 2, a fine cleaning device for photovoltaic modules in a large-scale photovoltaic power station, including a water tank 2, the water outlet of the water tank 2 is connected to one end of a first water delivery pipeline 4-1, and the other end of the first water delivery pipeline 4-1 extends to the photovoltaic module string 1 Above the area, a water delivery pump 6 is installed on the first water delivery pipeline 4-1 near the water outlet of the water tank 2, and the other end of the first water delivery pipeline 4-1 is connected with a flushing water pipe 10, and the number of flushing water pipes 10 is the same as The number of photovoltaic module strings 1 is the same, and the flushing water pipe 10 is equipped with a controllable solenoid valve 9; the backwater tank 5 is arranged under the photovoltaic module string 1, and the back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com