Multi-use detecting device for rear floor cross beam of automobile

A technology of rear beams and inspection tools, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of wasting materials and resources, occupying space, and unable to install cars firmly, so as to increase the length and improve the utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

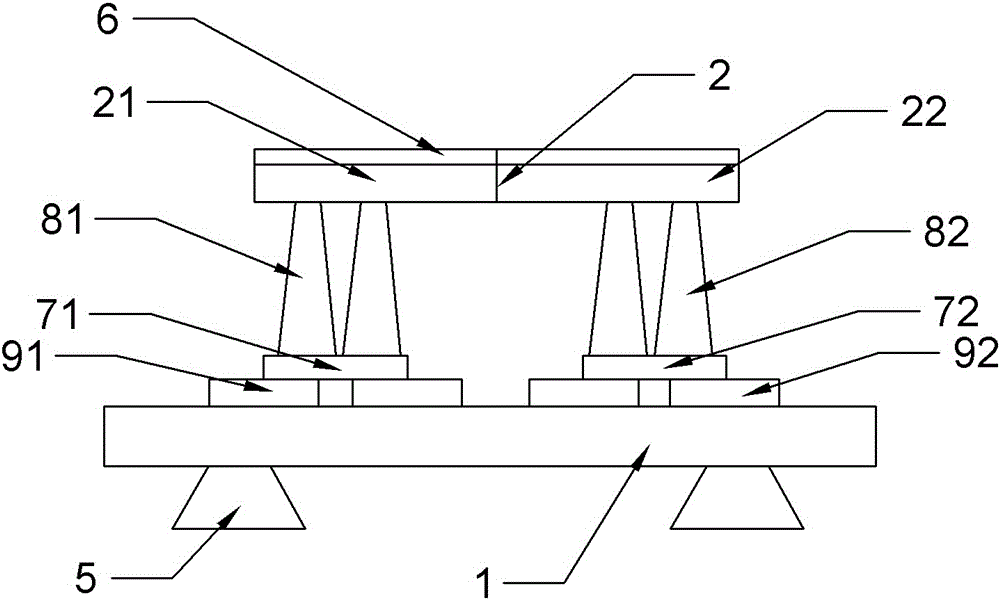

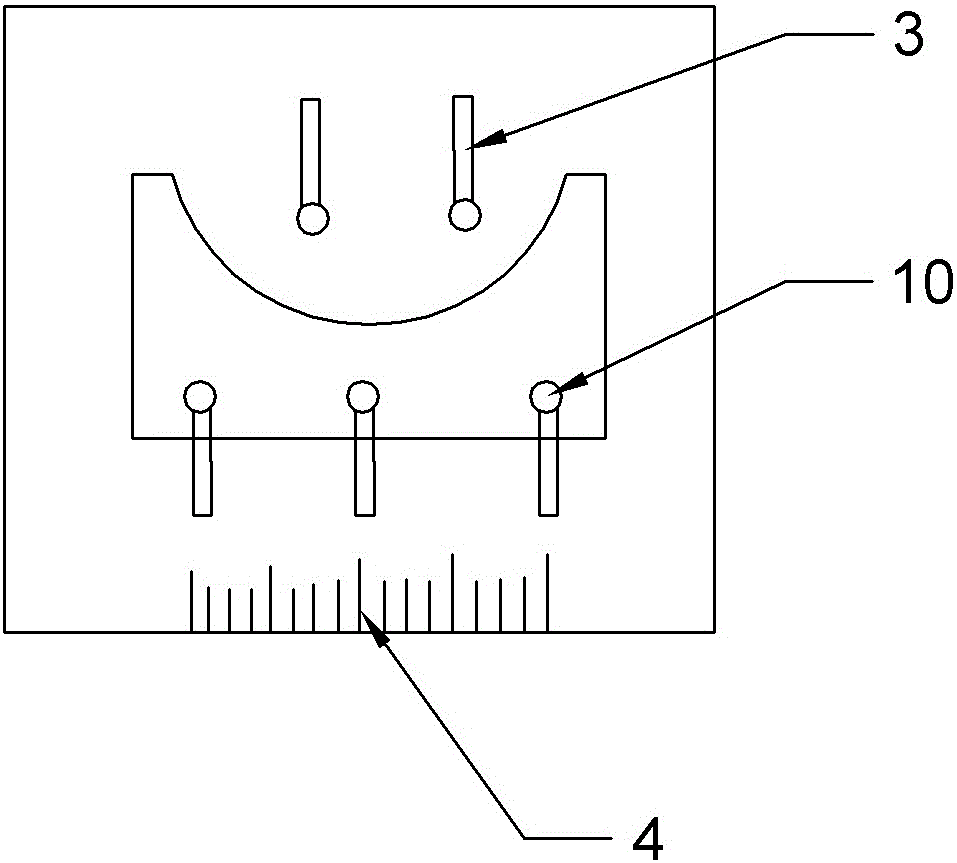

[0020] Such as figure 1 with figure 2 As shown, the multi-purpose inspection tool for the rear beam of the vehicle floor includes a inspection tool frame 1 and a strip body 2. The inspection tool frame 1 is a rectangular plate, and a chute is provided on the inspection tool frame 1. The chute There are five movable supports 3 fixedly connected to both sides of the movable support 3, and the movable supports 3 can move upwards and downwards. The movable supports are provided with contacts 10, which are used to fix the stamping parts and ensure the smoothness of the stamping parts. Both the inspection tool frame 1 and the strip body 2 are made of Gr12 material, and the hardness is controlled at HRC58 after heat treatment. The material is relatively wear-resistant and prolongs the service life. A scale 4 is provided on the upper edge of the inspection tool frame 1, which can be used to detect the distance of the strip body 2 sliding in the chute, and ensure that the distance is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap