Sprue cup structure for casting

A sprue cup and sprue technology, which is applied to casting equipment, casting molten material containers, manufacturing tools, etc., can solve the problems of hindering the smooth flow of molten metal, inconvenient replacement, corrosion or damage of filter screens, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

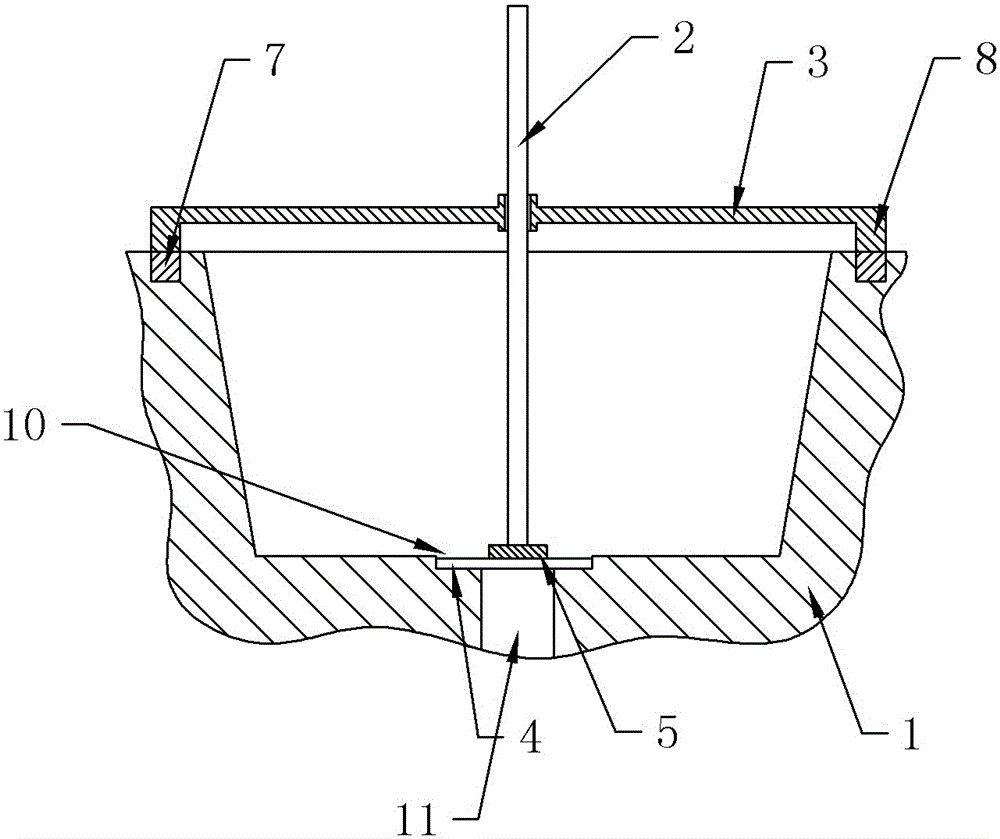

[0019] The upper end of the sprue cup body 1 is embedded with two magnets 7, and the sliding bracket 3 is provided with an absorber 8 that cooperates with the two magnets 7. In actual use, the absorber can be a magnet, an iron block, etc. In this embodiment, the absorber The pieces are iron blocks. When installing the sliding bracket 3, the installation can be completed by absorbing the absorbing piece to the corresponding two magnets 7, which is more efficient and quicker.

[0020] Specific workflow:

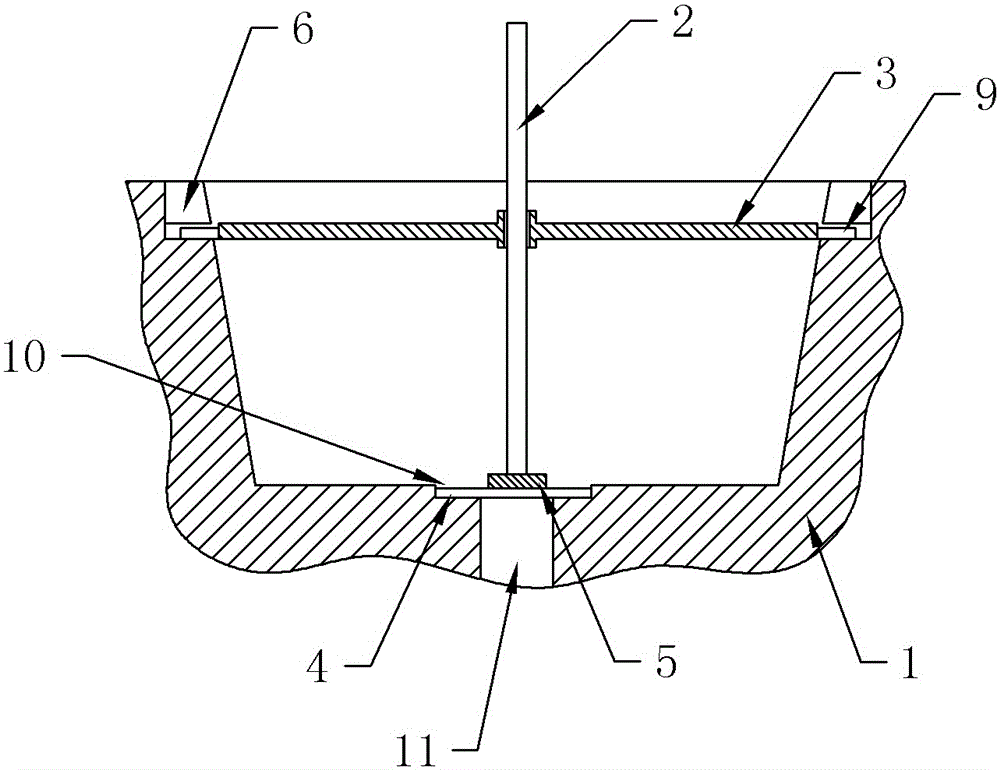

[0021] Take embodiment 1 as an example for illustration, such as figure 1 As shown, when filtering molten metal with many inclusions, first move the sliding rod 2 downwards, move the filter screen 4 at the lower end of the sliding rod 2 to the installation groove 10, and pour the molten metal into the sprue cup 1, so that the inclusions contained in the molten metal can be filtered; when filtering the molten metal with less inclusions, first move the sliding rod 2 upwards to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com