Polishing machine for machining hydraulic drive thin steel pipe and use method of polishing machine

A technology of hydraulic transmission and polishing machine, which is applied in the direction of surface polishing machine tools, metal processing equipment, grinding/polishing equipment, etc. It can solve the problems of difficult dust removal and low polishing precision of hydraulic transmission thin steel pipes, so as to improve the polishing precision, Keep it clean and improve the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

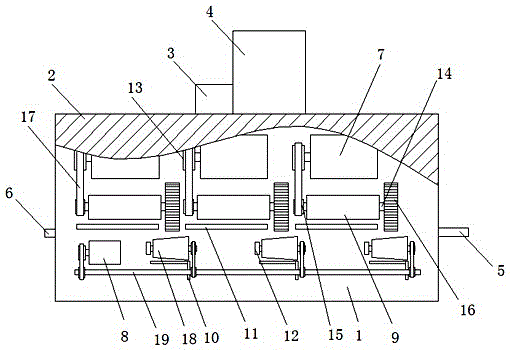

[0019] As shown in the accompanying drawings: a polishing machine for processing thin steel pipes with hydraulic transmission and its use method, the polishing machine includes a main machine 1 and a protective cover 2 arranged on the main machine 1, and the safety of the equipment is improved through the protective cover 2 , it is characterized in that: the outer wall of the main machine 1 is provided with a suction motor 3, a dust collection chamber 4, a pipe inlet 5, and a pipe outlet 6, and the suction motor 3 is connected with the dust collection chamber 4, through the suction The wind motor 3 and the dust collection room 4 can suck out the dust in the polishing machine in time, can keep the working environment clean and tidy, and improve the safety of the operator. The main engine 1 is provided with a motor 7, a transmission motor 8, a positioning Block 9, support block 10, protective plate 11, fixed block 12, and on motor 7, transmission motor 8, be provided with rotatin...

Embodiment 2

[0026] As shown in the accompanying drawings: a polishing machine for processing thin steel pipes with hydraulic transmission and its use method, the polishing machine includes a main machine 1 and a protective cover 2 arranged on the main machine 1, and the safety of the equipment is improved through the protective cover 2 , it is characterized in that: the outer wall of the main machine 1 is provided with a suction motor 3, a dust collection chamber 4, a pipe inlet 5, and a pipe outlet 6, and the suction motor 3 is connected with the dust collection chamber 4, through the suction The wind motor 3 and the dust collection room 4 can suck out the dust in the polishing machine in time, can keep the working environment clean and tidy, and improve the safety of the operator. The main engine 1 is provided with a motor 7, a transmission motor 8, a positioning Block 9, support block 10, protective plate 11, fixed block 12, and on motor 7, transmission motor 8, be provided with rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com