Platen Support Guide for Two-Platen Injection Molding Machines

A formwork support and guide device technology, applied in the field of injection molding equipment, can solve the problems of increasing the friction coefficient between the moving formwork and the Colin column, the influence of the performance of the clamping cylinder seal, and increasing the risk of hydraulic oil leakage, so as to avoid deformation. , Reduce the requirements of machining accuracy, reduce the effect of friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

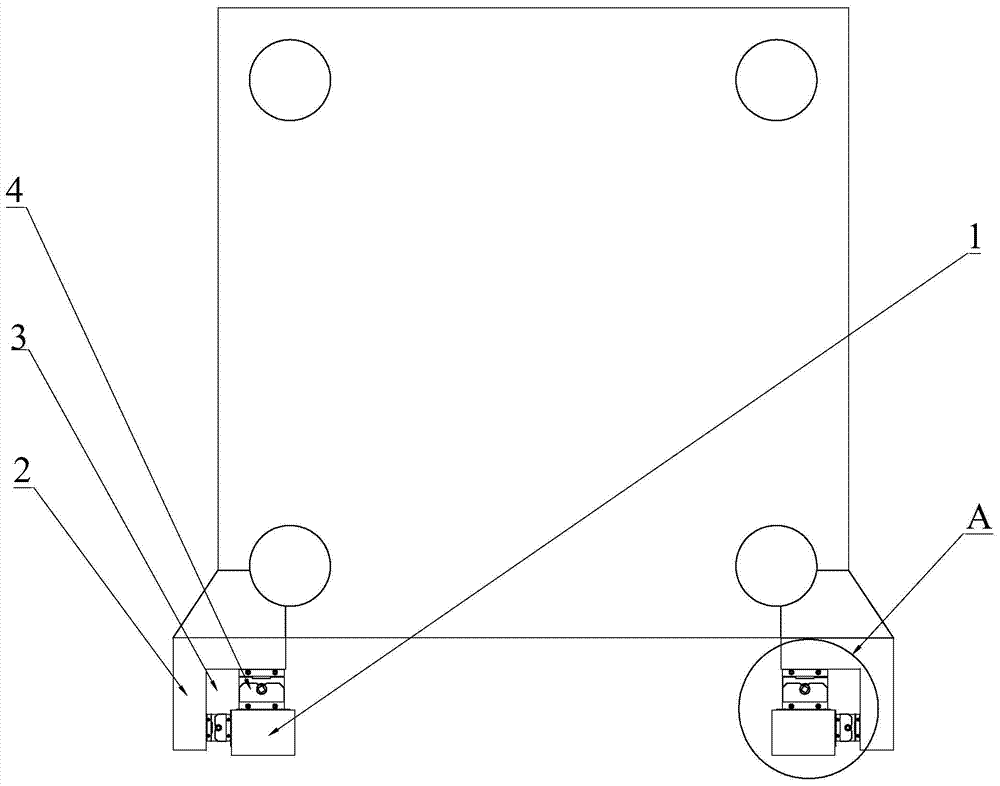

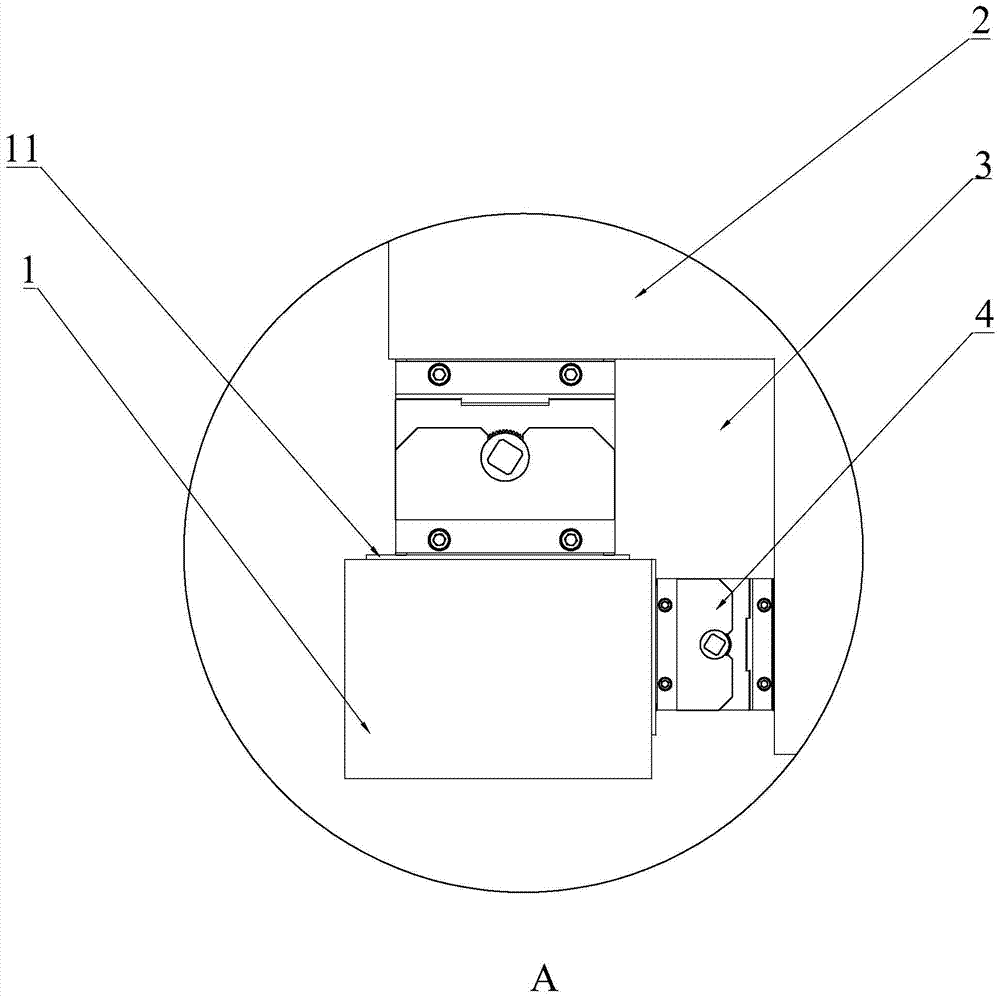

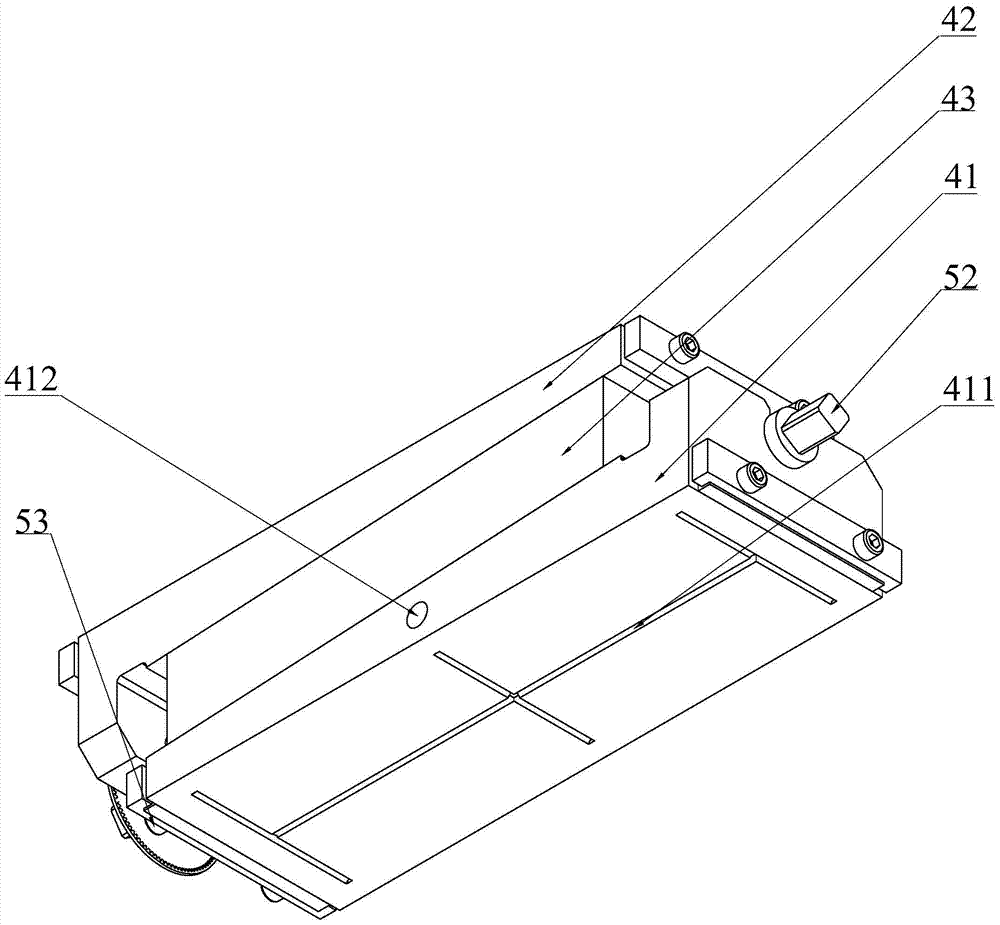

[0024] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7As shown, the present invention provides a template support and guide device for a two-platen injection molding machine with the following structure, including a horizontally arranged frame rail 1 and a template support foot 2 provided with a groove 3, said The top and side surfaces of the rack track are provided with a support adjustment module 4 that interferes with the groove 3, and the support adjustment module 4 includes a first wedge-shaped block 41 that is slidably matched with the rack track 1 and is fixedly connected with the formwork support foot 2. The second wedge-shaped block 42, the middle block 43 interferes between the first wedge-shaped block 41 and the second wedge-shaped block 42, and the support adjustment module 4 is provided to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com