High-density optical fiber distribution frame

An optical fiber distribution frame and high-density technology, applied in the field of communication equipment, can solve the problems of disordered wiring and inconvenient maintenance of wiring and wiring, and achieve the effects of improving uniformity, increasing the scope of use, and reducing confusion and entanglement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

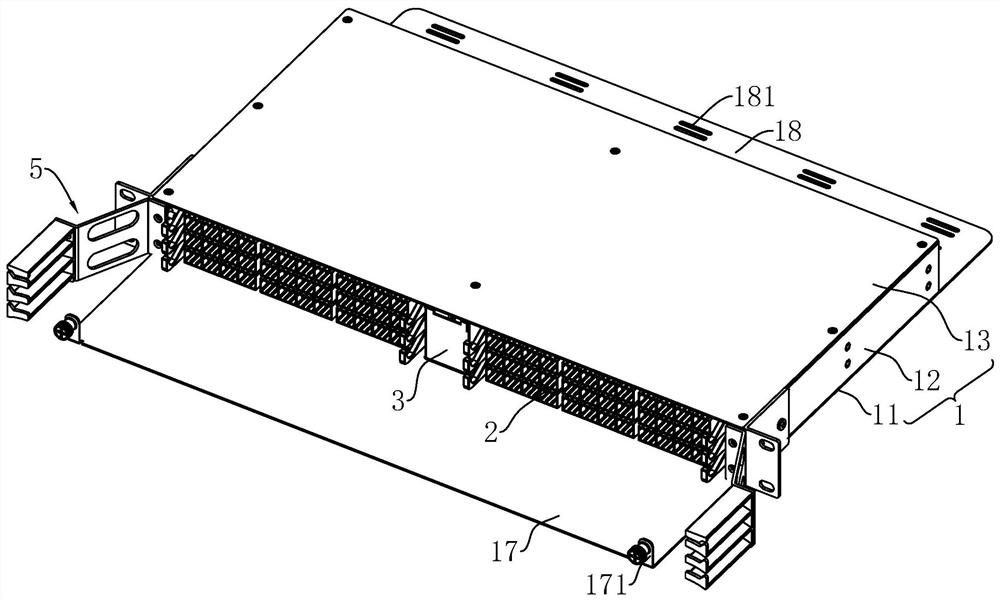

[0045] refer to figure 1 , a high-density optical fiber distribution frame, including a distribution box body 1 and a number of fiber-contained mold boxes 2 slidingly connected to the distribution box body 1, and the two ends of the distribution box body 1 are provided with openings.

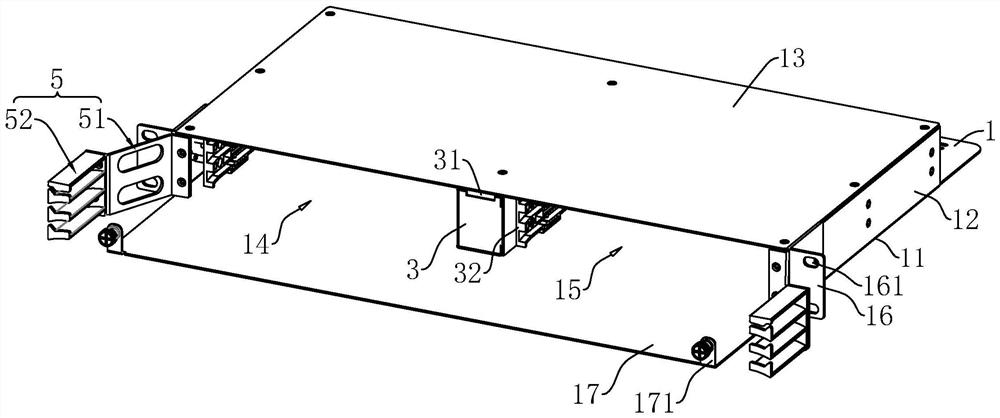

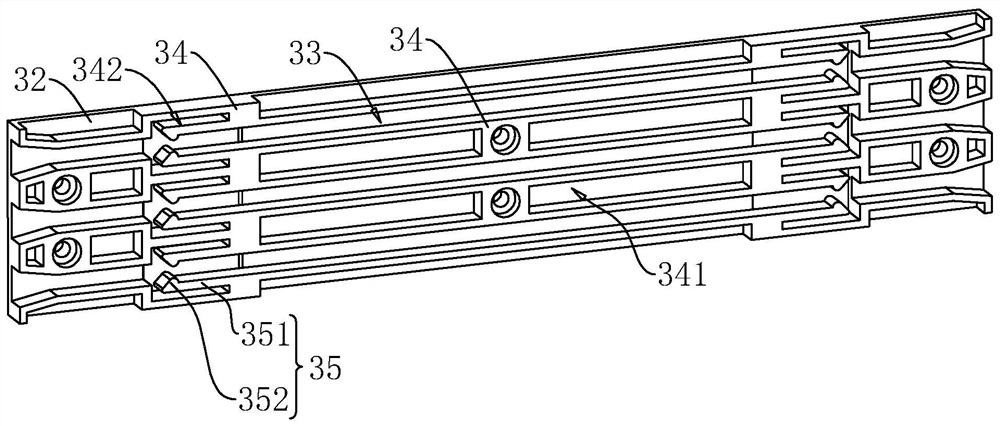

[0046] refer to figure 2 The distribution box body 1 includes a bottom plate 11, a pair of side plates 12 fixedly connected to the upper end surfaces on both sides of the bottom plate 11 and a top plate 13 fixedly connected to the upper end surfaces of the side plates 12, the bottom plate 11, the side plates 12 and the top plate 13 surround into the installation cavity. The distribution box body 1 is provided with a spacer 3 that divides the installation cavity into a first installation cavity 14 and a second installation cavity 15, the spacer 3 is parallel to the side plate 12, and the lower end surface of the spacer 3 is fixedly connected to the inner wall of the bottom plate 11 , the upper...

Embodiment 2

[0057] refer to Figure 8 , Figure 9 The difference between this embodiment and Embodiment 1 is that the second connecting plate 512 includes a fixed plate 5121 and a sliding plate 5122, the fixed plate 5121 is hinged to the first connecting plate 511 through the first hinge shaft 514, and the sliding plate 5122 Slidingly connected to the fixed plate 5121 , the end of the sliding plate 5122 away from the fixed plate 5121 is hinged to one side of the third connecting plate 513 through a hinge shaft. The fixed plate 5121 is provided with a sliding cavity for the sliding connection of the sliding plate 5122, the axial directions of the first hinge shaft 514 and the second hinge shaft 515 are vertically arranged, and the outer wall of the fixed plate 5121 is threaded with a butt joint. The sliding plate 5122 has a limit screw 53 that fixes the sliding position of the sliding plate 5122 .

[0058] refer to Figure 9 , Figure 10 The two sides of the second dust-proof plate 42 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com