A progressive forming method of polymer sheet based on metal backplane support

A progressive forming, metal backing technology, applied in processing platforms/substrates, additive processing, processing and manufacturing, etc., can solve problems such as instability and distortion, poor rigidity and strength of polymer sheets, and improve stress conditions, Achieve effective control and improve the effect of overall twist deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

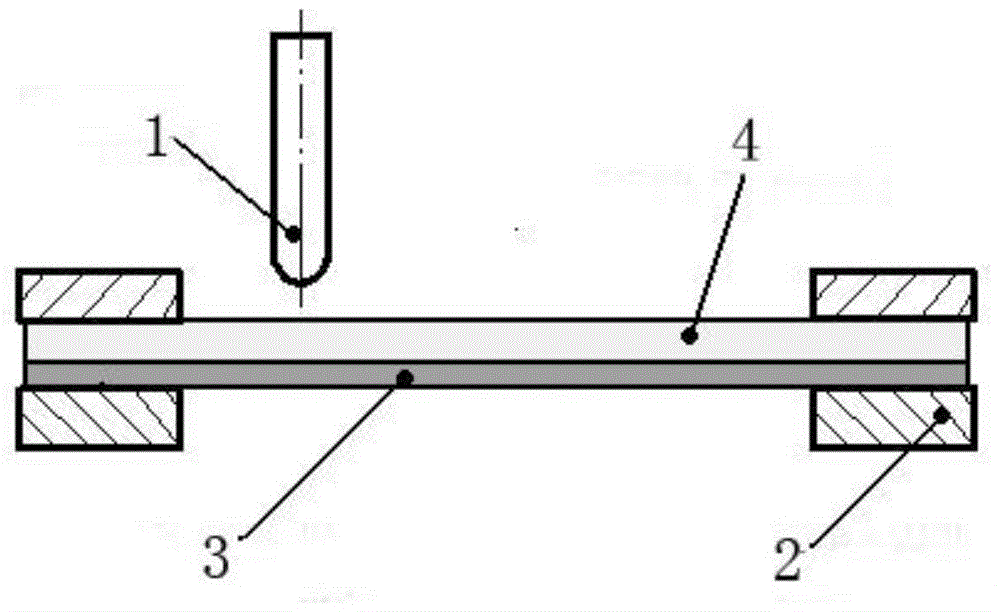

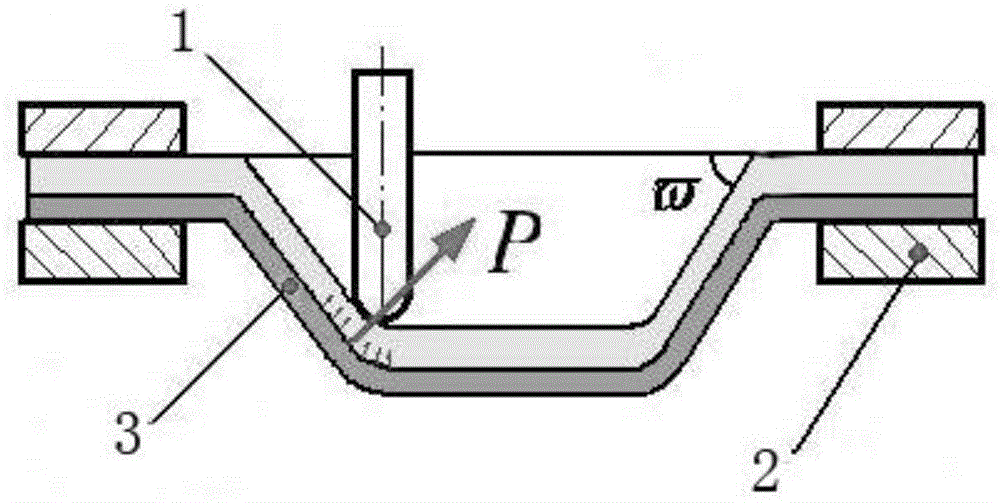

[0024] The invention relates to a method for progressive forming of polymer plates based on metal backplate support, which can effectively improve the quality of progressively formed parts of polymer plates, and specifically includes the following steps:

[0025] 1) According to the shape of the polymer part, determine its main forming direction.

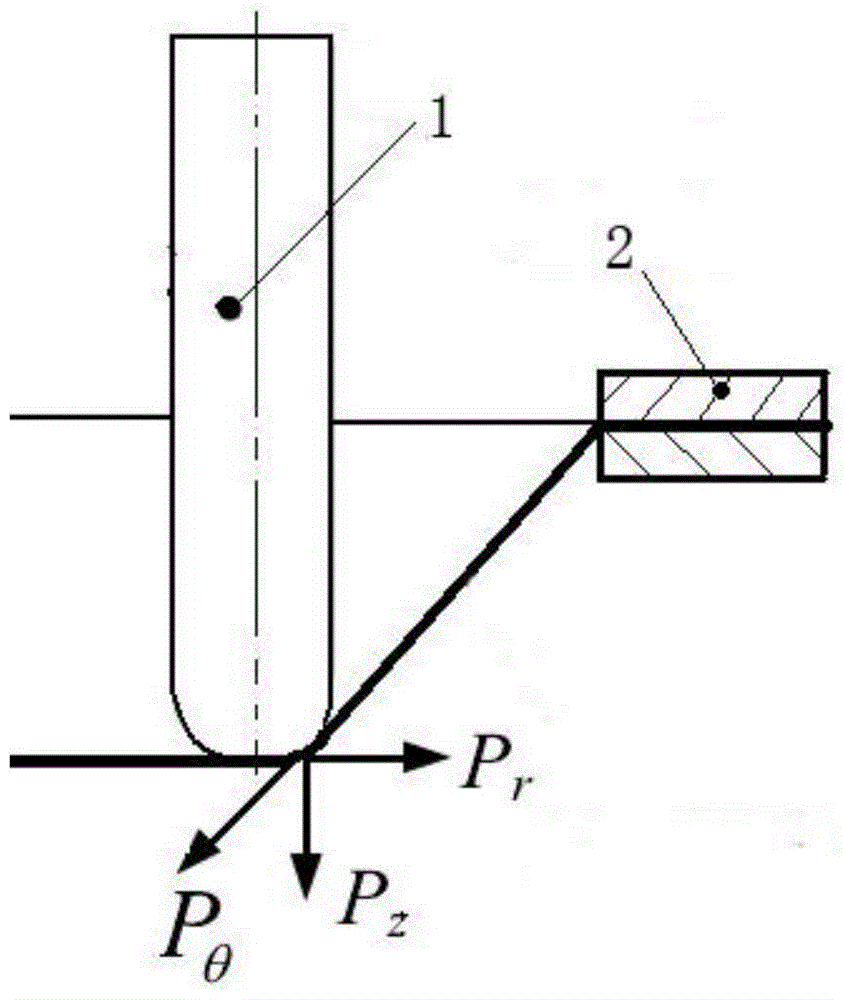

[0026] 2) According to the main forming direction of the part in step 1), find out the maximum forming angle of the part Forming angle here is the angle between the normal vector of the processing position and the Z axis.

[0027] 3) Select the metal support back plate according to the material and thickness of the polymer parts. Here, the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com