Numerical control hydraulic machine

A technology of hydraulic press and pressure oil source, which is applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve the problem of high tonnage, achieve the effect of simplifying the mechanical structure, simple structure, and saving external guide devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

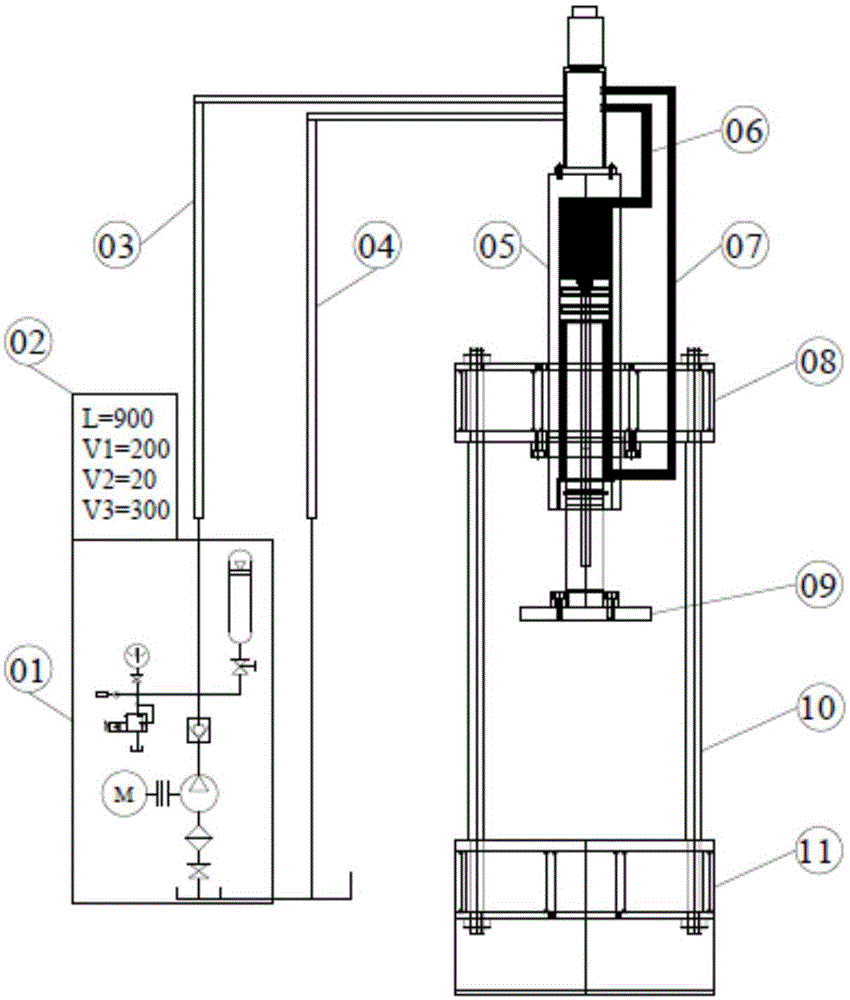

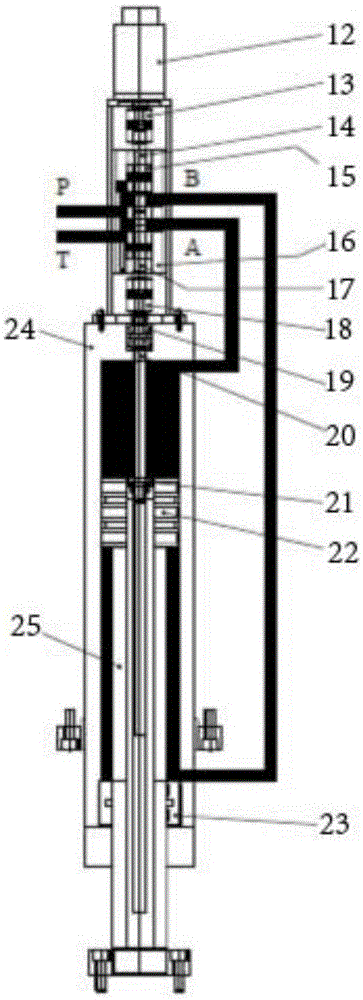

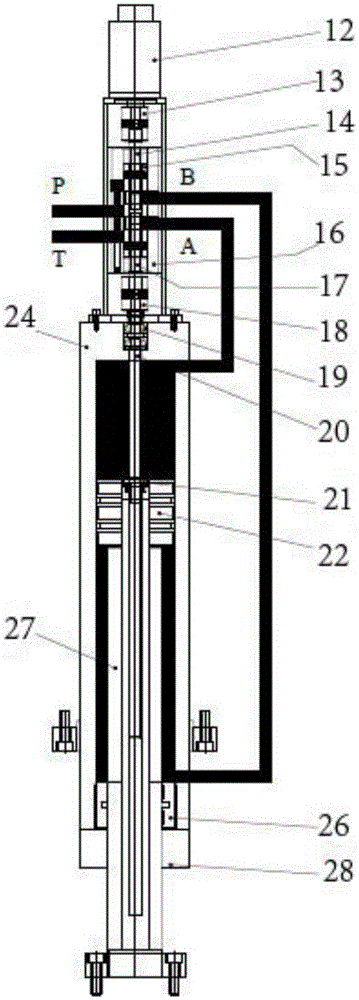

[0024] A numerically controlled hydraulic machine, including a pressure oil source 01, an operation screen 02, a high pressure oil pipe 03, an oil return pipe 04, a numerically controlled oil cylinder 05, an oil pipe in the upper chamber of the oil cylinder 06, an oil pipe in the lower chamber of the oil cylinder 07, a pressure head 09, and a mounting frame for the numerically controlled oil cylinder. The top of the source 01 is provided with an operation screen 02, and the top of the pressure oil source 01 is also provided with an oil outlet. The oil return port is connected to one end of the oil return pipe 04, and the other end of the oil return pipe 04 is connected to the numerical control oil cylinder 05. The numerical control oil cylinder 05 includes a servo motor 12, a valve body 16 and a cylinder body 24, and the servo motor 12 is set on the top of the valve body 16 , the lower end of the valve body 16 is provided with a cylinder body 24, the valve body 16 is connected ...

Embodiment 2

[0032] A numerically controlled hydraulic machine, including a pressure oil source 01, an operation screen 02, a high pressure oil pipe 03, an oil return pipe 04, a numerically controlled oil cylinder 05, an oil pipe in the upper chamber of the oil cylinder 06, an oil pipe in the lower chamber of the oil cylinder 07, a pressure head 09, and a mounting frame for the numerically controlled oil cylinder. The top of the source 01 is provided with an operation screen 02, and the top of the pressure oil source 01 is also provided with an oil outlet. The oil return port is connected to one end of the oil return pipe 04, and the other end of the oil return pipe 04 is connected to the numerical control oil cylinder 05. The numerical control oil cylinder 05 includes a servo motor 12, a valve body 16 and a cylinder body 24, and the servo motor 12 is set on the top of the valve body 16 , the lower end of the valve body 16 is provided with a cylinder body 24, the valve body 16 is connected ...

Embodiment 3

[0040] A numerically controlled hydraulic machine, including a pressure oil source 01, an operation screen 02, a high pressure oil pipe 03, an oil return pipe 04, a numerically controlled oil cylinder 05, an oil pipe in the upper chamber of the oil cylinder 06, an oil pipe in the lower chamber of the oil cylinder 07, a pressure head 09, and a mounting frame for the numerically controlled oil cylinder. The top of the source 01 is provided with an operation screen 02, and the top of the pressure oil source 01 is also provided with an oil outlet. The oil return port is connected to one end of the oil return pipe 04, and the other end of the oil return pipe 04 is connected to the numerical control oil cylinder 05. The numerical control oil cylinder 05 includes a servo motor 12, a valve body 16 and a cylinder body 24, and the servo motor 12 is set on the top of the valve body 16 , the lower end of the valve body 16 is provided with a cylinder body 24, the valve body 16 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com