Rotating type heat-sealing and heat-pressing device of improved structure

A hot-pressing device and rotary technology, applied in packaging, transportation and packaging, rigid/semi-rigid container manufacturing, etc., can solve the problems of low production efficiency, high labor intensity, poor product quality, etc., and achieve flexible and automatic use High degree, the effect of reducing the error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

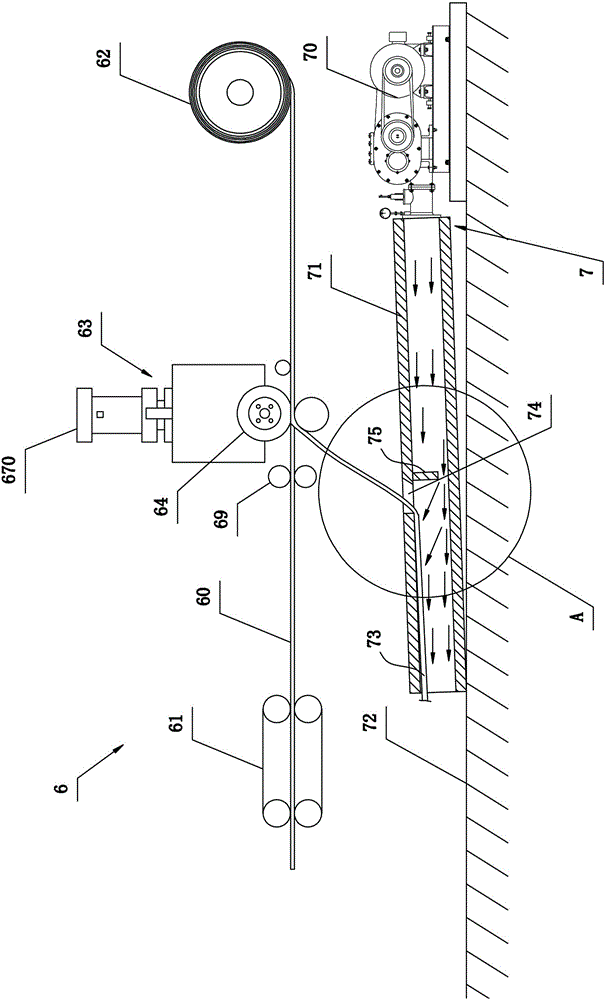

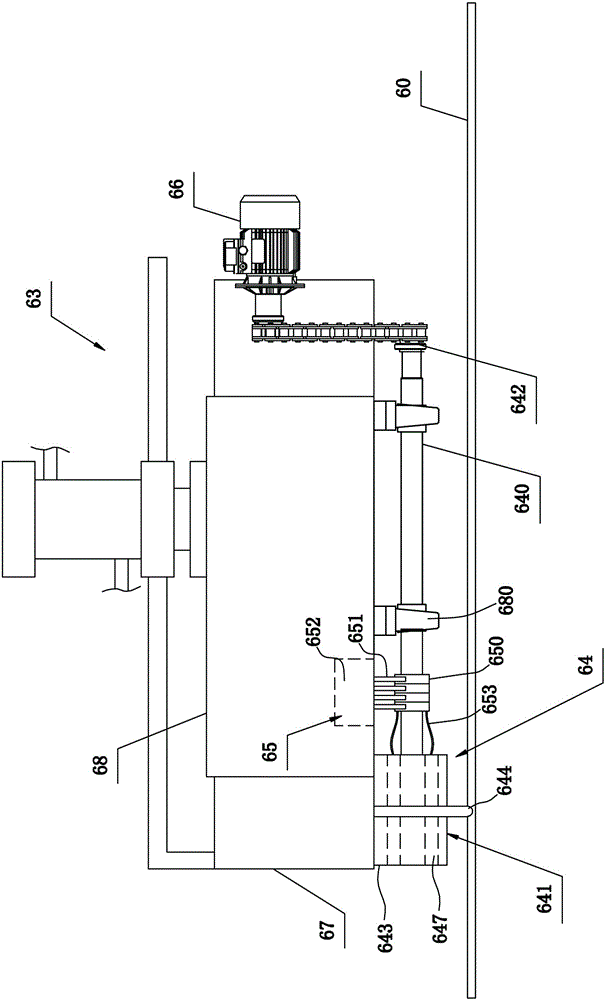

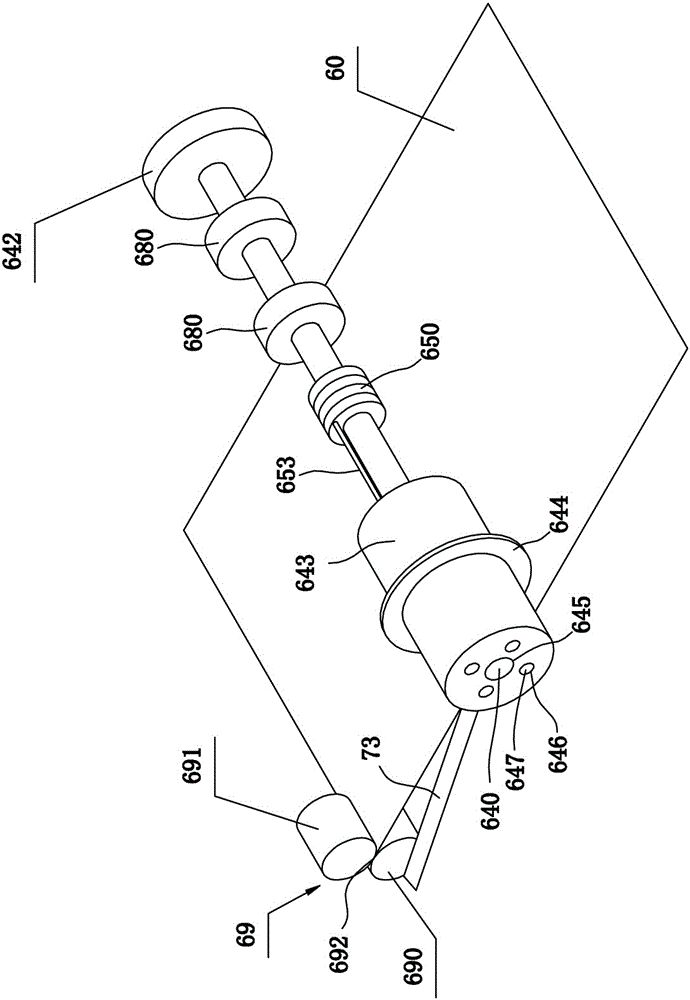

[0034] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5. A rotary heat-sealing and heat-pressing device 6 with improved structure includes a conveying component 61 for dragging the pearl cotton film or the bubble film 60 to walk, a feeding component 62 for placing the pearl cotton film or the bubble film 60, and a feeding component 62 for placing the pearl cotton film or the bubble film 60. A cutting assembly 63 for thermally pressing at least one side of the pearl cotton film or the bubble film 60, the cutting assembly 63 includes a frame, a rotary cutter 64 rotatably mounted on the frame, a rotary The component power supply unit 65 and a first drive unit 66 that drives the rotary cutter 64 to rotate, the first drive unit 66 is a motor. A heating unit is arranged on the rotary cutter 64, and the heating unit is electrically connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com