Biofilm sewage treatment device and biofilm in-situ testing method

A sewage treatment device and biofilm technology, applied in sustainable biological treatment, aerobic process treatment and other directions, can solve the problems of difficult to guarantee accuracy, small surface area of biofilm fillers, and high difficulty of biofilm, and achieve the promotion of uniform growth, Improve the efficiency of sewage treatment and reduce the effect of dead zone of water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

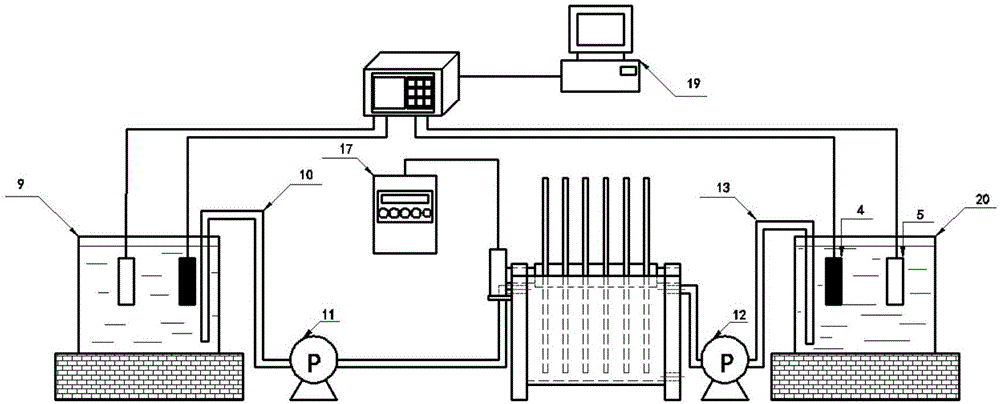

[0036] Microcosmic Mechanism Study of Hydraulic Retention Time on Treatment Effect of Biofilm Sewage Treatment Device

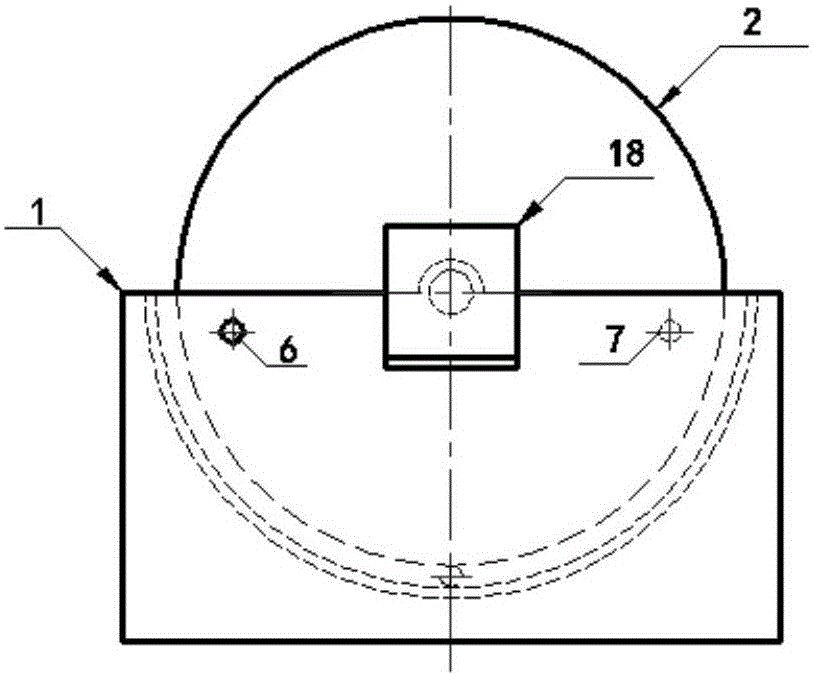

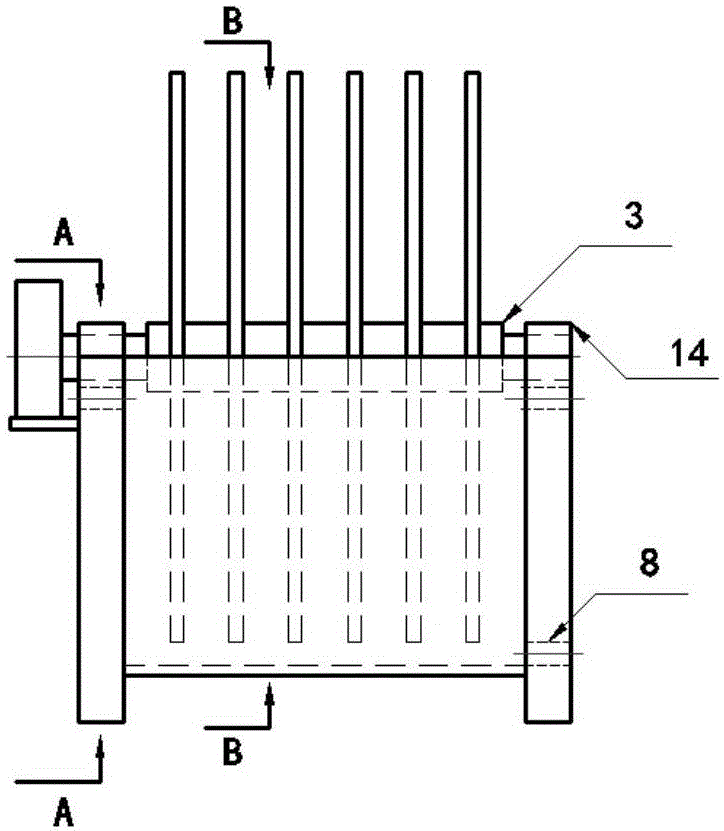

[0037] Three sets of biofilm sewage treatment devices were used for parallel tests. Each set of biofilm sewage treatment devices used 6 biofilm carrier discs. The discs were discs with a diameter of 25 cm and a thickness of 0.6 cm. Set up 8 biofilm test strips at random, and control the height of the water inlet and outlet holes. When there is water in and out of the concave tank, the immersion rate of the disk in the sewage is 40%.

[0038] The circular biofilm carrier disc is film-hanged by the activated sludge inoculation method. The method is as follows: use the remaining sludge of the urban sewage treatment plant as the inoculation sludge and artificially prepare the simulated sewage containing 40mg / L ammonia nitrogen according to a certain ratio. The mixture is stored in the sump, pumped into the concave water tank through the water inlet pump, the pump...

Embodiment 2

[0046] Microcosmic Mechanism Study on the Treatment Effect of Water Flow Shear Force on Biofilm Sewage Treatment Device

[0047] According to current literature reports, the water shear stress that biofilms can withstand is in the range of 0-2Pa. Using the device and sewage described in Example 1, keeping the pump flow rate of the biofilm sewage treatment plant constant, under the optimal hydraulic retention time conditions determined in Example 1, by changing the output of the pulse power supply and changing the rotating speed of the rotating shaft, different biofilms can be obtained. Surface water flow shear conditions. The shearing force of the water flow on the biofilm at different rotation radii of the biofilm carrier disk under different rotating speed conditions is calculated according to the calculation formula (2).

[0048] τ w = 0.8 · ρ · v · ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com