Automatic smearing equipment and automatic smearing production line

An automatic and equipment technology, applied in the field of automatic production equipment, can solve the problems of waste of easy cleaning liquid, increase of production cost, low efficiency of manual application, etc., and achieve the effect of saving human resources, reducing labor intensity and reducing staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

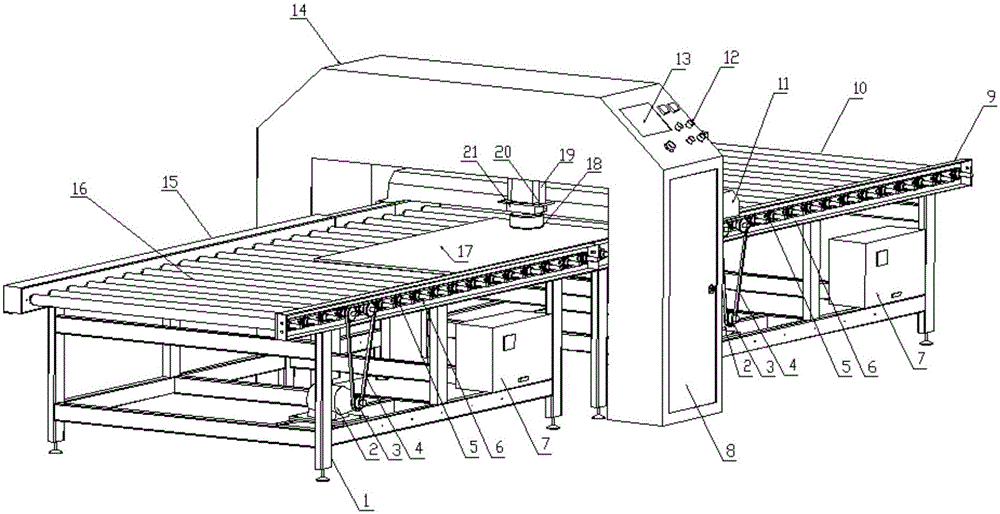

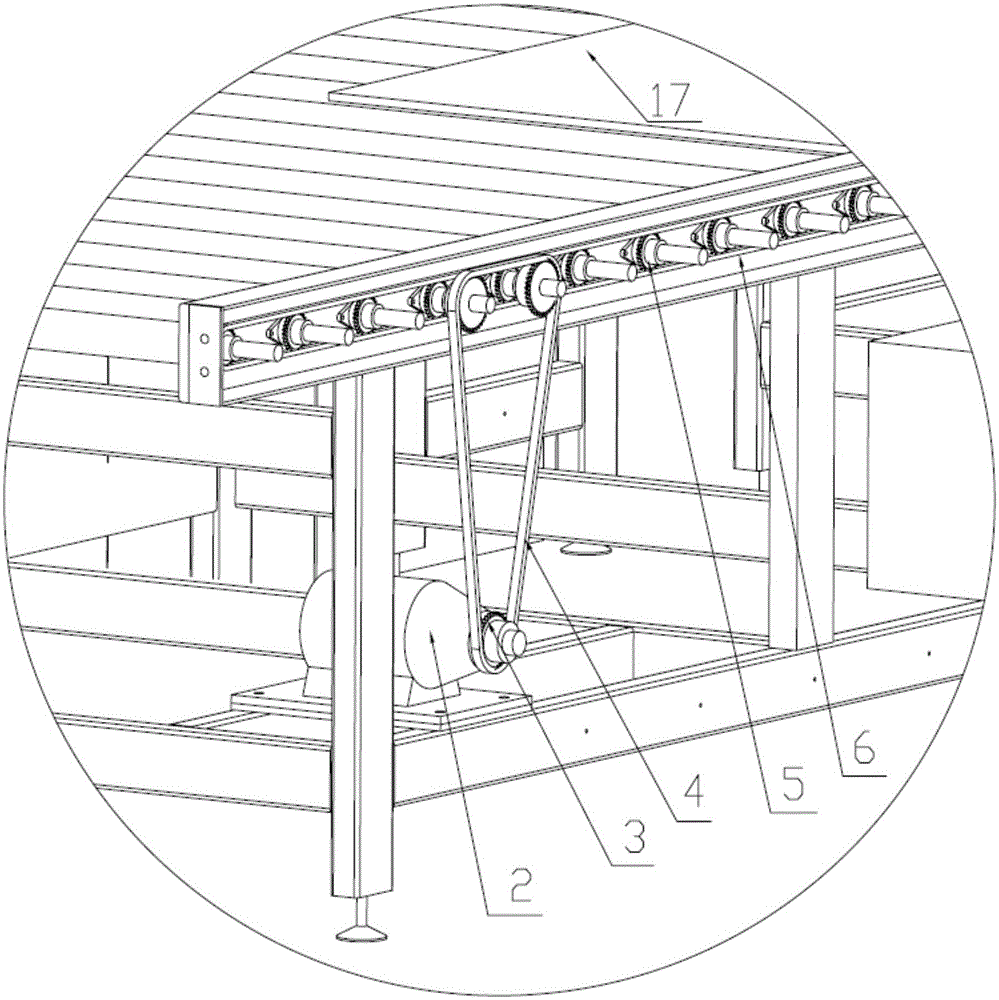

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

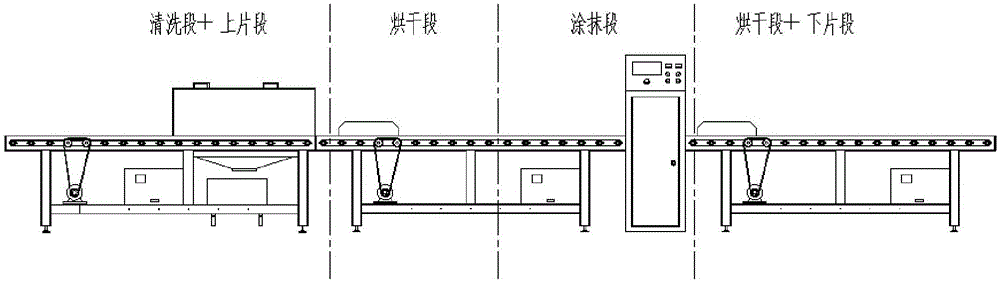

[0026] Such as figure 1 As shown, an automatic coating production line includes two parts: automatic cleaning machine and automatic rotary coating machine. It can be divided into four functional sections: cleaning section; drying section; smearing section; drying section. It can automatically complete the whole process of glass cleaning, glass drying, and glass cleaning liquid application, which can replace manual cleaning, manual handling, natural drying and manual application, which can greatly improve work efficiency. At the same time, reduce the number of direct staff in each process and save human resources for the factory. At the same time, the labor intensity is also reduced. The cleaning machine and the smearing machine use synchronous control motors to make the motor speed evenly equal. The cleaning part is composed of a cleaning box, a funnel basin and a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com