High-strength automatic-flow crack-pouring castable and preparation method thereof

A castable, high-strength technology, applied in the field of gap filling materials, can solve the problems of easy steel penetration, inconvenient construction, difficult combination, etc., and achieve the effect of no vibration, easy construction, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

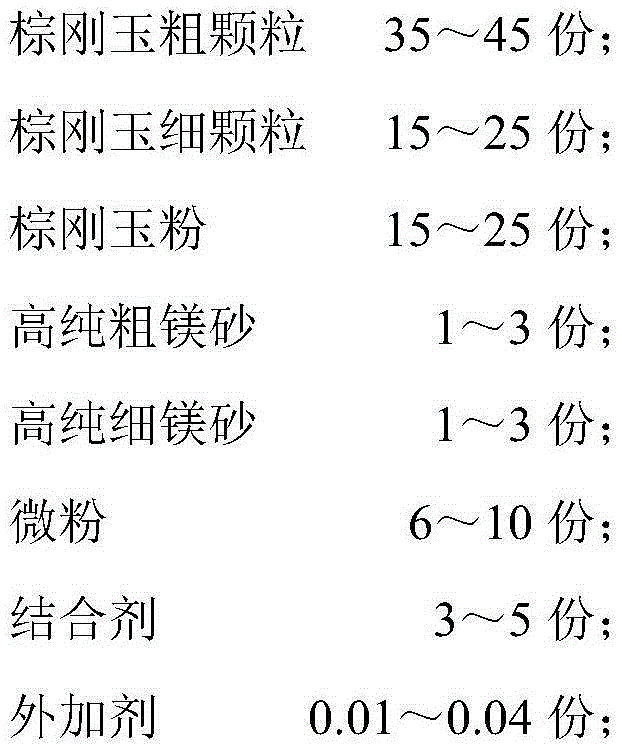

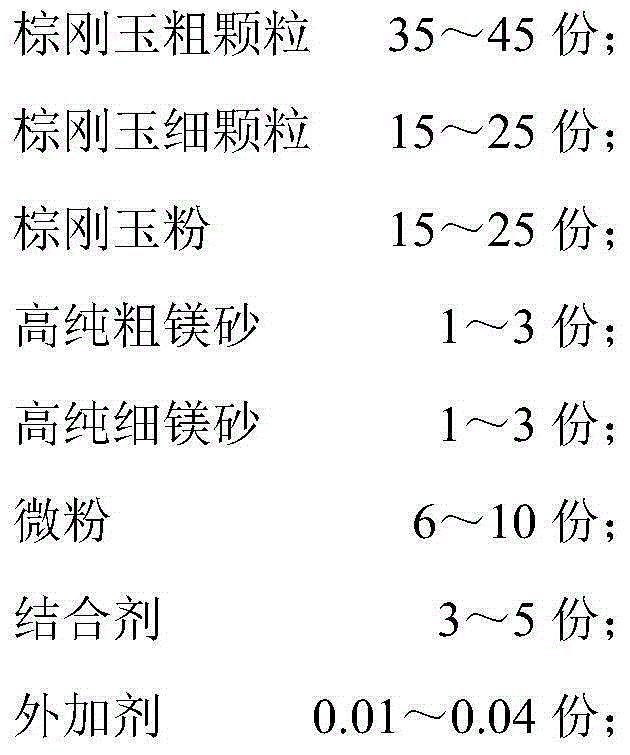

[0022] The high-strength self-flowing joint castable is made of the following materials according to the weight ratio:

[0023] Brown corundum particles (1-3㎜) 43 parts; brown corundum particles (0-1㎜) 20 parts; brown corundum powder (200 mesh) 20 parts; high-purity magnesia (0-1㎜) 2 parts, high-purity magnesia (200 mesh ) 2 parts, 8 parts of micropowder, 5 parts of binder, and 0.02 part of admixture.

[0024] Wherein, the micropowder adopts the mixture of alumina micropowder and silica fume powder, 7 parts of alumina micropowder, and 1 part of silica fume powder. The binder is sear-71 cement. The additive is a mixture of sodium hexametaphosphate and polyacrylamide, and its mass ratio is: 3 parts of sodium hexametaphosphate and 1 part of polyacrylamide.

[0025] The preparation method of the castable: Put the used refractory raw materials (brown corundum and high-purity magnesia) and micropowder in the mixer for 4 minutes; then add the binder and admixture to the mixer, and ...

Embodiment 2

[0027] The high-strength self-flowing joint castable is made of the following materials according to the weight ratio:

[0028] Brown corundum particles (1-3㎜) 41 parts; brown corundum particles (0-1㎜) 20 parts; brown corundum powder (200 mesh) 22 parts; high-purity magnesia (0-1㎜) 2 parts, high-purity magnesia (200 mesh ) 2 parts, 8 parts of micropowder, 5 parts of binder, and 0.02 part of admixture.

[0029] Wherein, the micropowder adopts the mixture of alumina micropowder and silica fume powder, 8 parts of alumina micropowder, 1 part of silica fume powder. The binder is sear-71 cement. The additive is a mixture of sodium hexametaphosphate and polyacrylamide, and its mass ratio is: 4 parts of sodium hexametaphosphate and 2 parts of polyacrylamide.

[0030] The preparation method of castable is the same as that of Example 1.

Embodiment 3

[0032] The high-strength self-flowing joint castable is made of the following materials according to the weight ratio:

[0033] Brown corundum particles (1-3㎜) 40 parts; brown corundum particles (0-1㎜) 21 parts; brown corundum powder (200 mesh) 21 parts; high-purity magnesia (0-1㎜) 3 parts, high-purity magnesia (200 mesh ) 2 parts, 8 parts of micropowder, 5 parts of binder, and 0.02 part of admixture.

[0034] Wherein, the micropowder adopts the mixture of alumina micropowder and silica fume powder, 6 parts of alumina micropowder, and 1 part of silica fume powder. The binder is aluminate cement. The additive is a mixture of sodium hexametaphosphate and polyacrylamide, and its mass ratio is: 3 parts of sodium hexametaphosphate and 1 part of polyacrylamide.

[0035] The preparation method of castable is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com