A kind of silver ammonium phosphotungstate compound salt catalyzes the method for synthesizing citrate

A technology of silver ammonium phosphotungstate and citrate, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid esters, etc., can solve the problems of poor reusability, complicated preparation process, and low activity, and achieve Environmental friendliness, simple preparation process, high surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

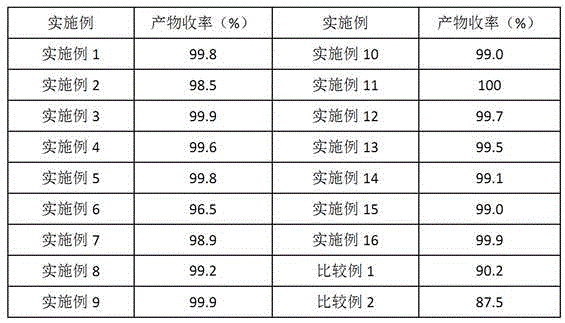

[0015] Add 19.21 g citric acid (0.1 mol), 33.35 g n-butanol (0.45 mol) and 0.38 g (NH 4 ) 0.5 Ag 0.5 h 2 PW 12 o 40 Catalyst, start stirring, raise the temperature to 155°C, start timing when the reflux phenomenon starts to appear in the condenser tube, and react for 4 hours. After the reaction system was cooled to room temperature, it was separated by filtration, and the filtrate was detected by gas chromatography. The product yields are shown in Table 1.

Embodiment 2

[0017] Using the same reaction conditions and detection method as in Example 1, only the amount of catalyst was changed to 0.20 g, and the product yield is shown in Table 1.

Embodiment 3

[0019] Using the same reaction conditions and detection method as in Example 1, only the amount of catalyst was changed to 0.80 g, and the product yield is shown in Table 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap