Minor-diameter cold roll hardening and tempering technology

A technology of cold rolling and small diameter, which is applied in the quenching and tempering process of small diameter cold rolling, which can solve the problems of long production cycle and large number of counts, and achieve the effect of clean quenching and tempering process and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

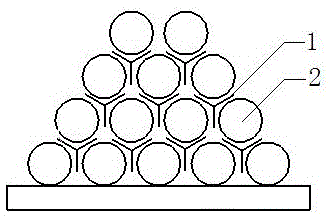

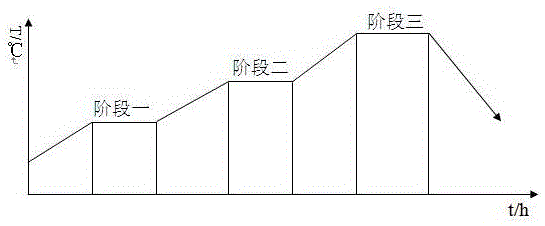

[0025] Select a small-diameter cold roll for quenching and tempering treatment, such as Figure 1-2 As shown, the specific process is: (1) Carry out flaw detection on the roll blank 2; (2) Roughly process the qualified roll blank 2 according to the drawing; (3) Put the roll blank 2 into the furnace, and determine the bottom stacking five Support roll blanks 2, and then successively reduce and stack roll blanks 2 upwards layer by layer, and stack fourteen roll blanks 2 in total. The roll blanks 2 are separated by brackets 1 and the distance between the roll blanks 2 is guaranteed to be 10mm; (4) Carry out heat treatment on the roll billet. In stage one, the temperature is raised to 350°C for preheating and heat preservation for 2 hours. In stage two, the temperature is raised to 650°C for heat treatment and heat preservation for 2 hours. In stage three, the temperature is raised to 900°C for heat treatment and heat preservation for 1 hour. The description is: the heating rate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com