Three-dimensional braided materials based on space group p4 symmetry

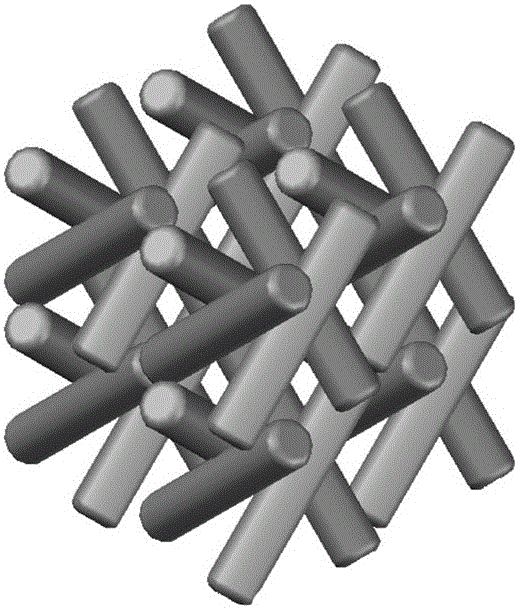

A three-dimensional weaving and space group technology, which is applied in the direction of braids, textiles and papermaking, can solve the problems of high process cost, optimize the performance of composite materials, and low processing efficiency, and achieve simple weaving process methods, excellent mechanical properties, and geometric structures. solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

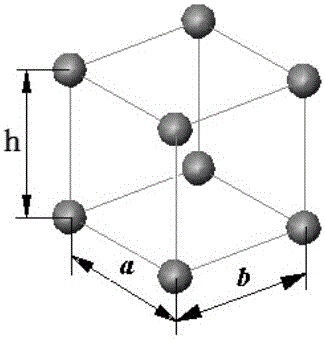

[0044] The following describes the space group-based of the present invention with reference to the accompanying drawings The specific implementation of the symmetrical three-dimensional braided material: the unit in the braided material refers to the representative volume unit. In this article and in the claims It stands for the same meaning as P4.

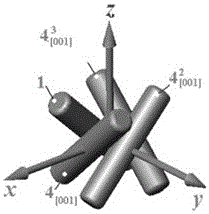

[0045] 1. A three-dimensional braided geometric structural unit that satisfies the symmetry of point group 4

[0046] In three-dimensional coordinate system xyz Suppose the z axis is the rotation axis, and the group elements satisfying the knitting point group 4 are (or ), the four rotation operations in point group 4, Is the generator of point group 4, which is considered to be around Shaft turned The rotation of the angle corresponds to the matrix of the group elements of point group 4 as follows

[0047] , ,

[0048] , .

[0049] The rotational symmetry operation corresponding to the group elements of space point group 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com