Corrugated steel web compound web structure

A technology of corrugated steel webs and combined webs, which is applied in buildings, bridges, etc., can solve the problems of heavy welding workload of welding stud connectors, difficulty in piercing reinforcement of steel plate connectors, and affecting the quality of concrete pouring, so as to reduce welding The effect of reducing workload, shortening the construction period on site, and facilitating fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

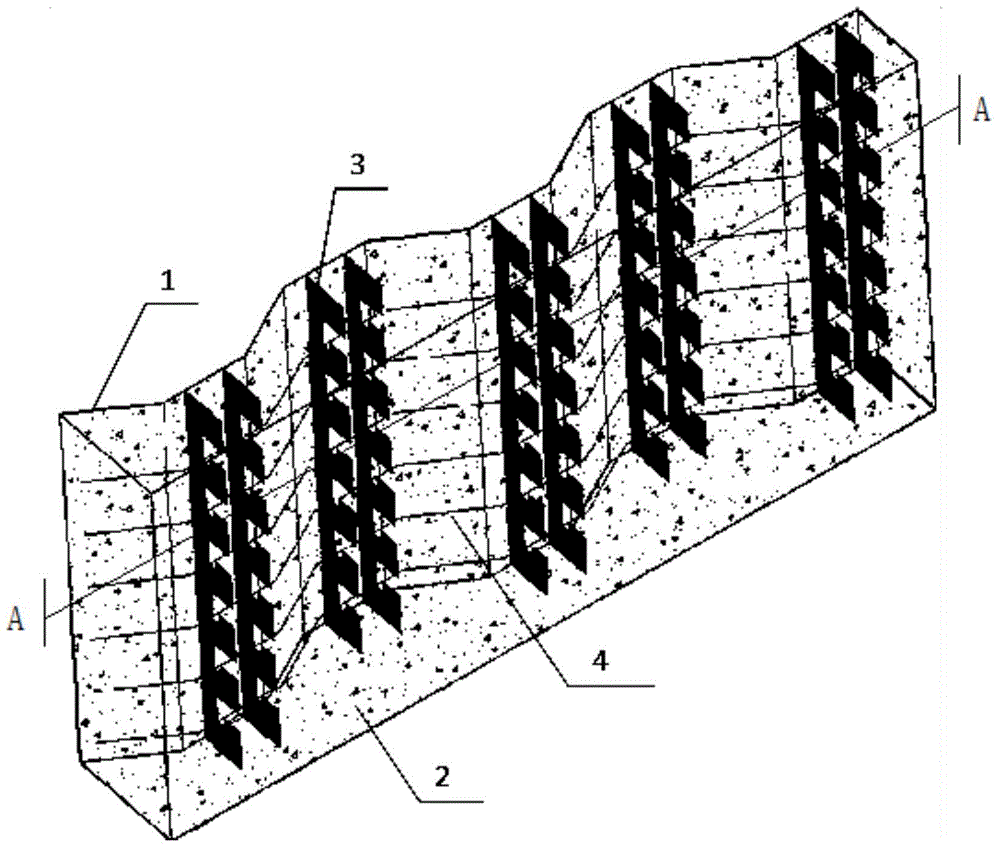

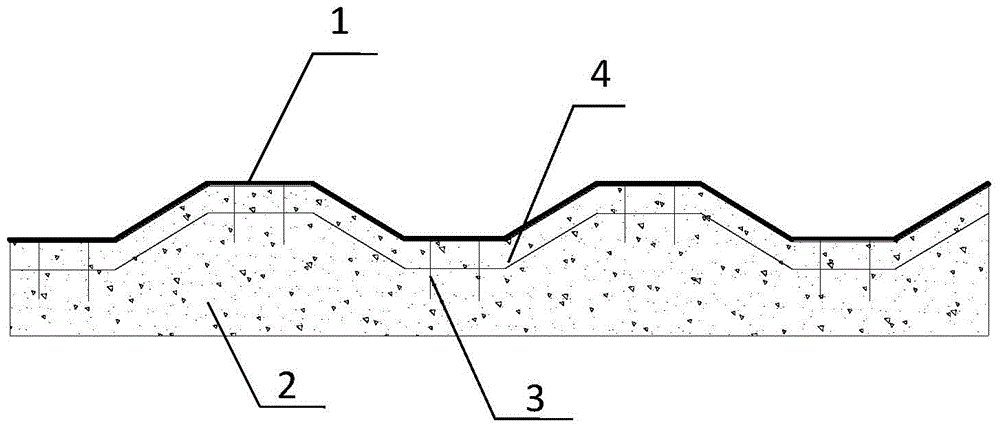

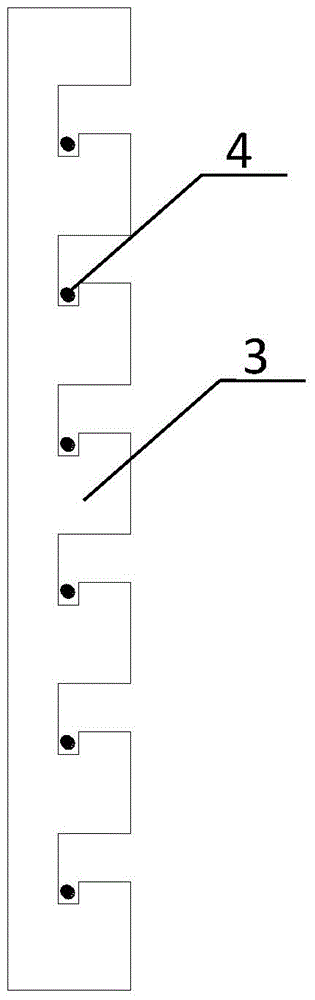

[0021] Such as Figure 1~3 The schematic diagram of the composite web structure of the corrugated steel web of the present invention is shown, including a corrugated steel web 1 , lining concrete 2 , steel plates 3 and through steel bars 4 .

[0022] A steel plate 3 is vertically fixed on the flat steel plate inside the corrugated steel web 1, optimally, two steel plates 3 form a group, and are arranged on the same flat steel plate on the corrugated steel web 1; the free end side of the steel plate 3 Opening, the steel plate 3 opening is provided with through steel bars 4, and the lining concrete 2 is wrapped and arranged on the outside of the corrugated steel web 1, steel plate 3 and through steel bars 4 to form an integrated structure, wherein there are multiple openings, at the bottom of the opening structure with downward grooves forming an open type structure. The bending angle of the penetrating steel bar 4 is consistent with the bending angle of the corrugated steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com