Rebar sleeve grouting connection member for prefabricated assembled type concrete component and connection method

A prefabricated assembly, steel sleeve technology, applied in building components, structural elements, building reinforcements, etc., can solve the problems of high centering precision of steel bars to be connected, complicated steel bar connection process, high labor intensity, etc. High efficiency, high practical value, and labor-saving and time-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

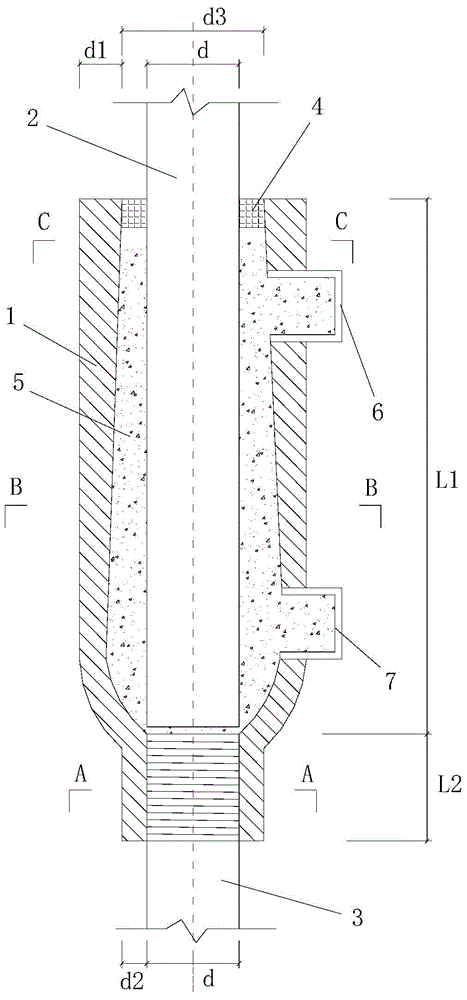

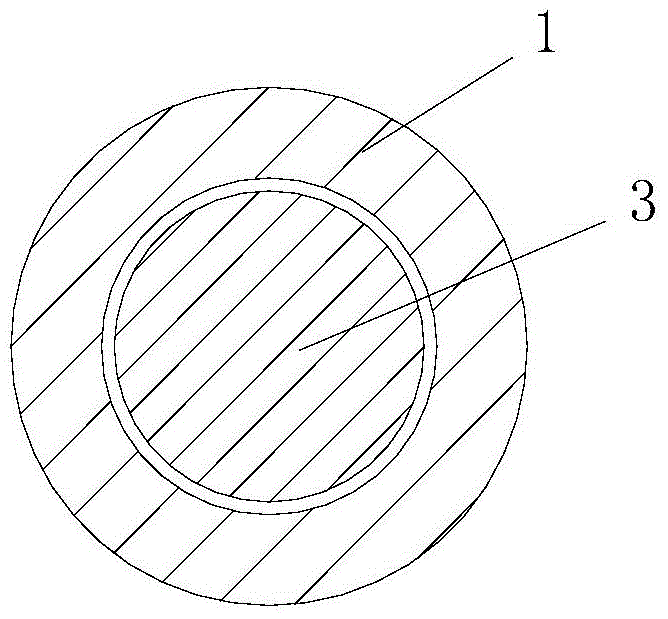

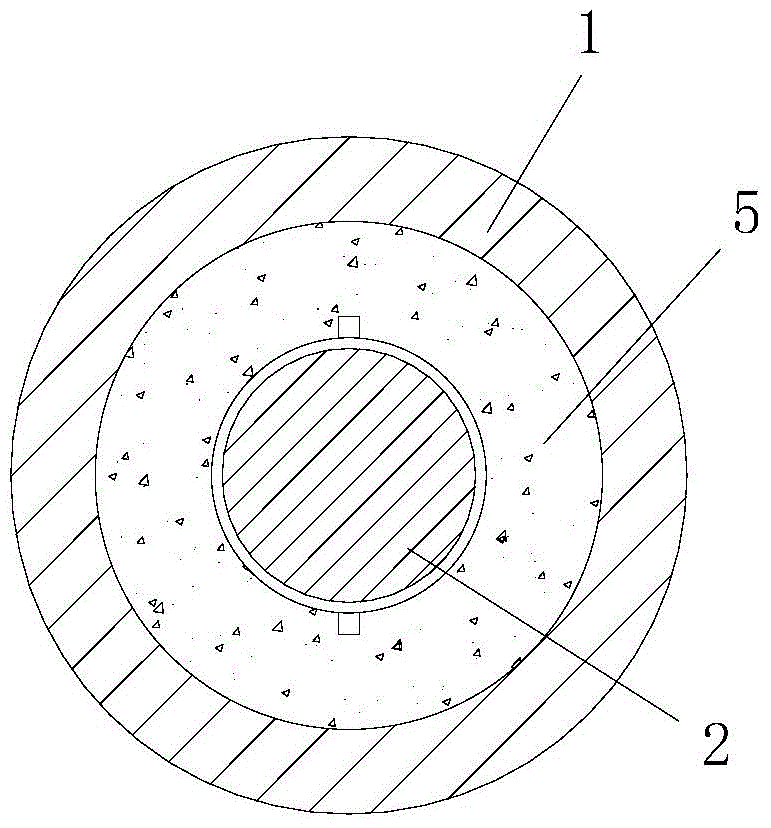

[0037] Such as figure 1 The shown prefabricated concrete component steel sleeve grouting connector includes a metal sleeve 1 for connecting inserted steel bars 2 and pre-embedded steel bars 3, a sealing gasket 4 arranged on the upper end of the metal sleeve 1 and a grouting The grouting structure 5 formed by the grouting material in the cavity between the metal sleeve 1 and the inserted steel bar 2, the inserted steel bar 2 is a ribbed steel bar, and the connection end of the embedded steel bar 3 is a threaded connection end. The metal sleeve 1 is divided into an upper cylinder section, a middle connecting cylinder section and a lower cylinder section from top to bottom, the upper cylinder section, the middle connecting cylinder section and the lower cylinder section are arranged coaxially and the inner cavities of the three connected. The upper tube section and the middle connecting tube section form a grouting tube, and the inserted steel bar 2 is inserted into the grouting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com