Judging method for vertical shaft drilling process dynamic regulation on basis of slag material analysis

A technology of dynamic adjustment and determination method, which is applied in the fields of earthwork drilling, wellbore/well components, etc. It can solve the problems of single way, failure to dynamically adjust the drilling process, and inability to effectively adapt to geological changes, so as to improve reliability. performance, ensure construction safety and project quality, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

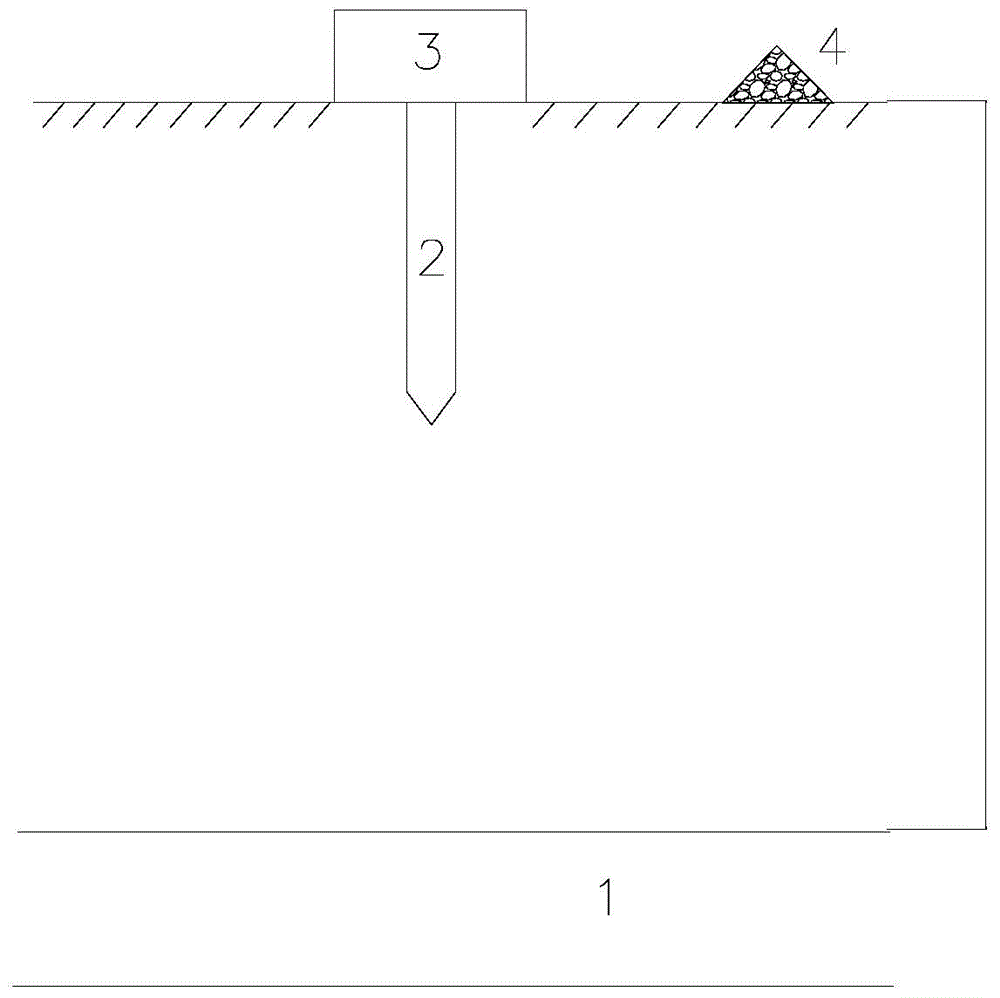

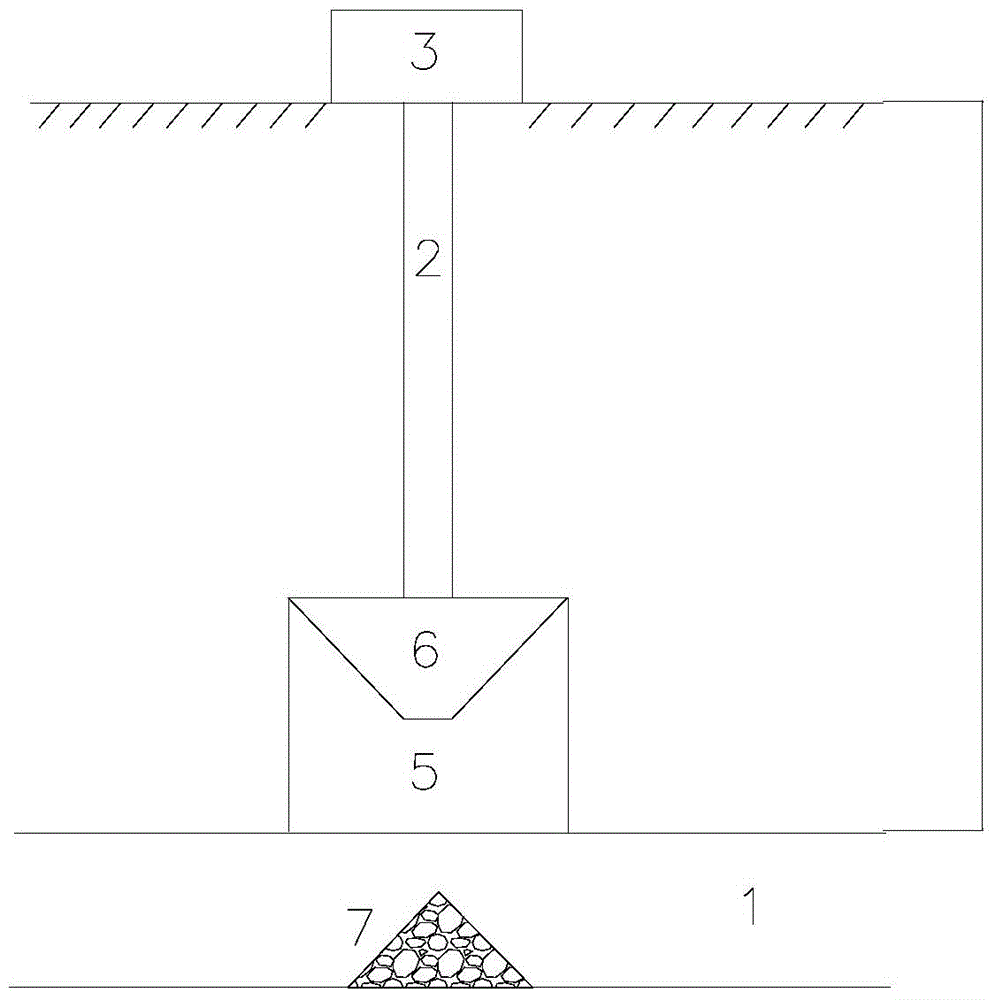

[0016] figure 1 It is a schematic diagram of shaft pilot hole drilling of the present invention; figure 2 It is a schematic diagram of vertical shaft reaming drilling of the present invention. The judging method of the dynamic adjustment of the shaft drilling process based on the slag material analysis in this embodiment includes the following steps: Utilize the raise drilling machine 3 to carry out pilot hole drilling, regularly salvage and drill rock slag sampling analysis; Preliminarily determine the lithology of shafts at different depths; select the process parameters for reaming drilling at different depths according to the determined lithology of shafts at different depths; use the raise drilling machine 3 and drill according to the selected reaming Reaming 5 is carried out according to the process parameters. In this embodiment, according to the geological conditions provided by the geological survey, the pilot hole 2 with a diameter of 28 cm is drilled downward from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com