A self-convection horizontal axis tidal current energy generation device

A power generation device and self-convection technology, which is applied in hydroelectric power generation, ocean energy power generation, engine components, etc., can solve the problems that the impeller angle cannot meet the high-efficiency power generation, the blade pitch mechanism is complicated, and the reliability of the unit is reduced, so as to achieve simple installation, High reliability, the effect of solving the problem of commutation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below with reference to the drawings and embodiments.

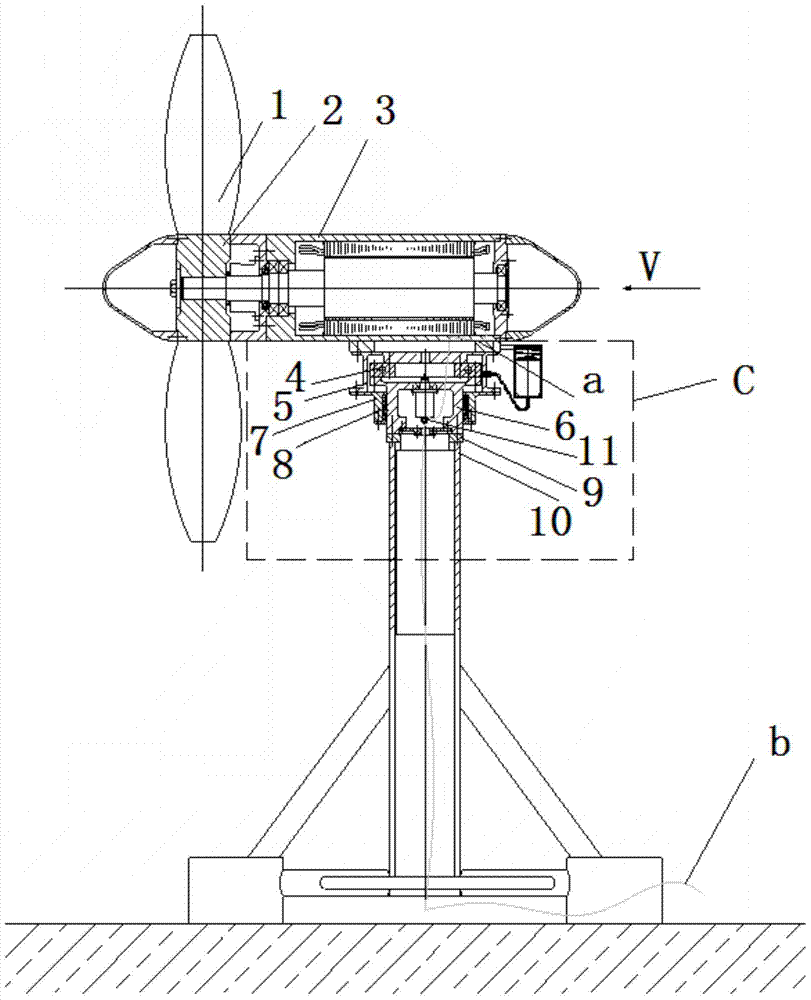

[0012] Such as figure 1 As shown, the present invention provides a self-convection type horizontal axis tidal current power generation device, which includes two parts: an impeller generator set and a self-convection device. The impeller generator set includes a blade 1, a hub 2 and a generator 3; the blade 1 is connected to the generator 3 via the hub. The blade 1 and the hub 2 are fixedly connected, and the pitch mechanism is omitted; the hub 2 and the generator 3 are directly connected through the main shaft, and the direct drive mode is adopted, and the speed increasing device is omitted. The side of the blade 1 facing the generator 3 is the oncoming surface (the current direction V is like figure 1 (Shown), the end of the generator 3 close to the blade 1 is called the front end, and the end far away from the impeller 1 is called the tail end.

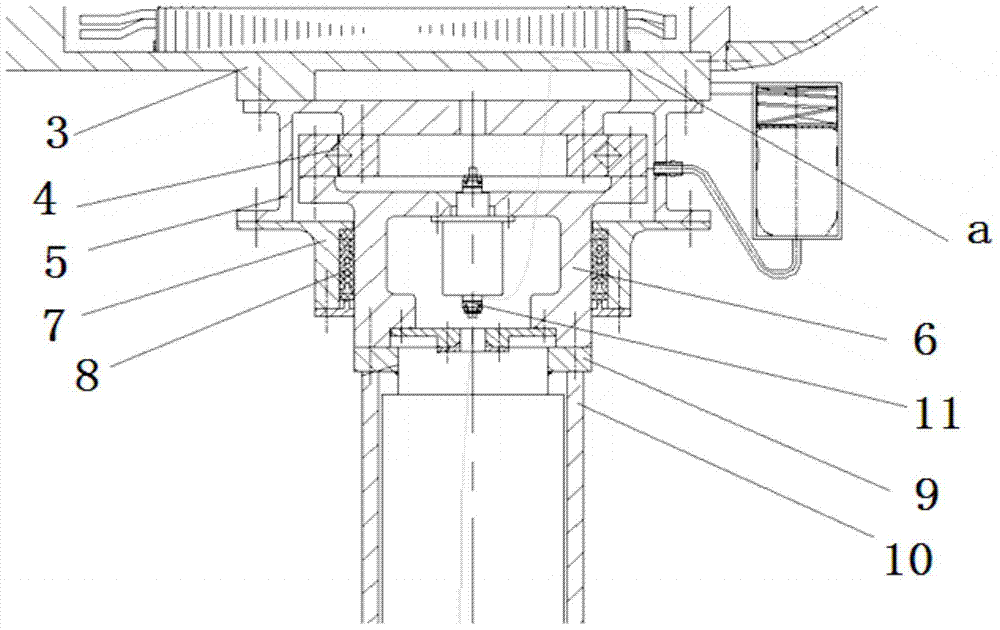

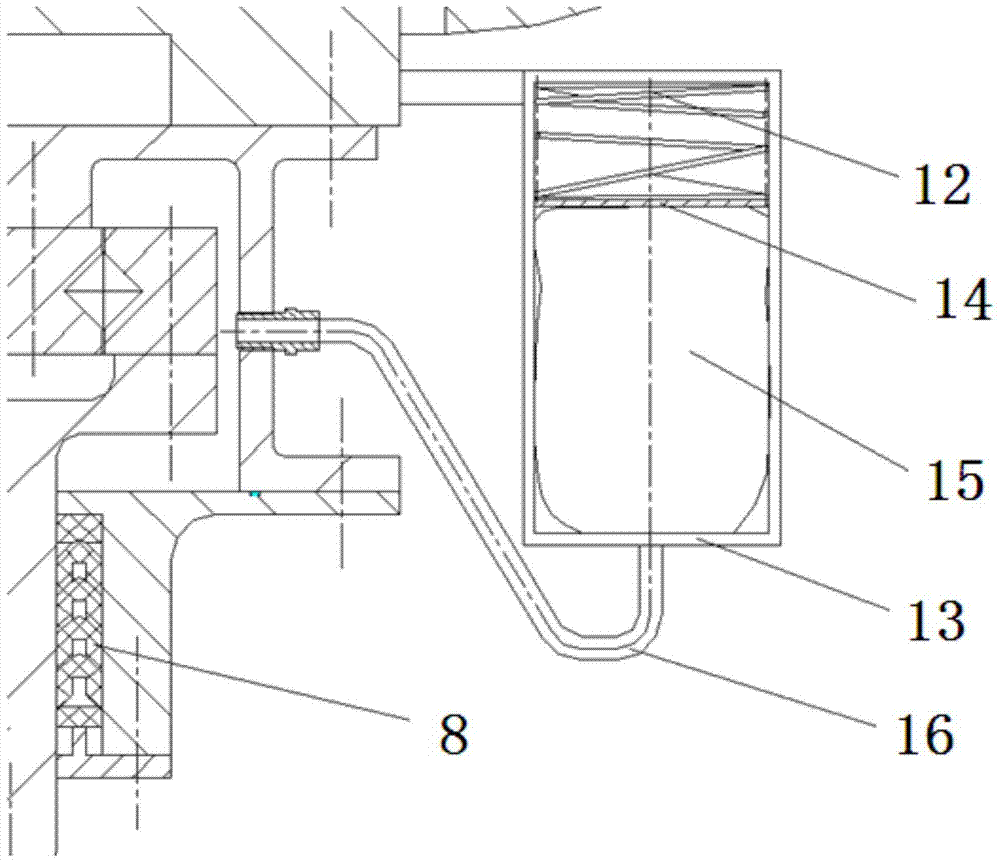

[0013] Such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com