Unit braking cylinder with hand braking device

A technology of unit brake cylinder and hand brake, which is applied to the operating mechanism of railway vehicle brakes, railway brake systems, brake actuators, etc. Problems such as large piston stroke and large external dimensions meet the needs of fast truck loading and operation, convenient maintenance and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

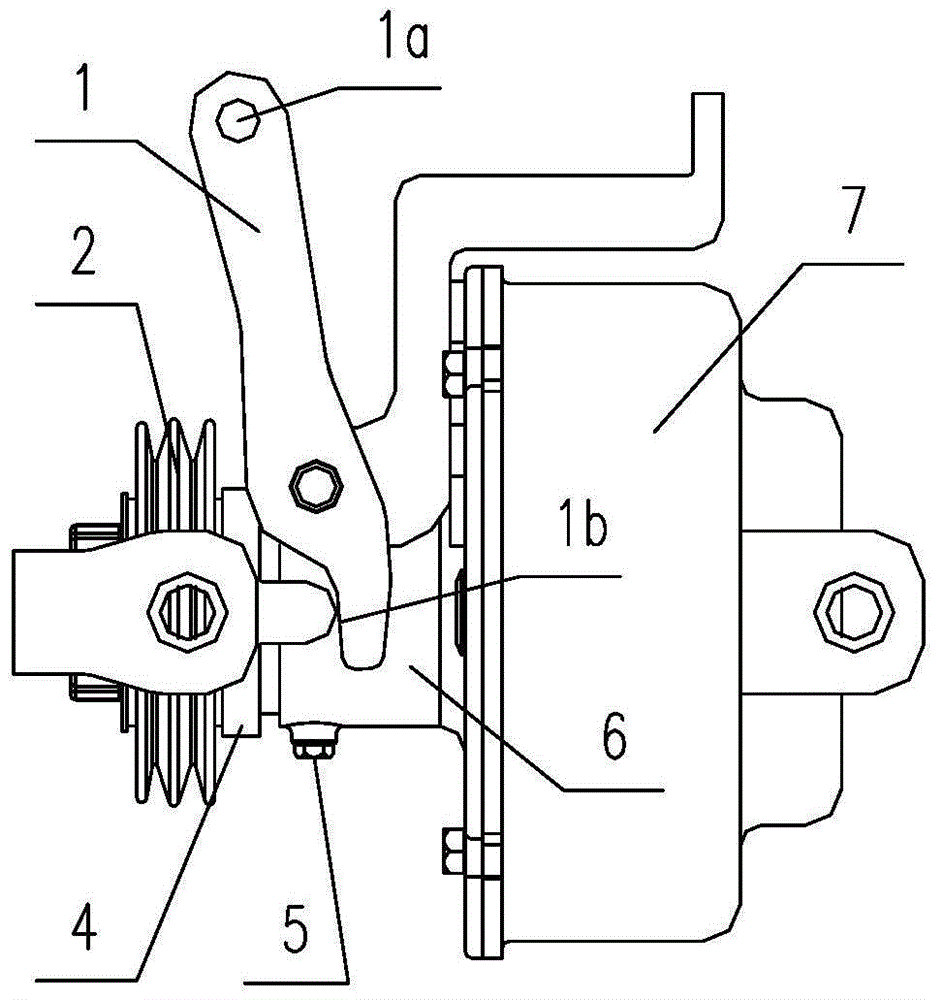

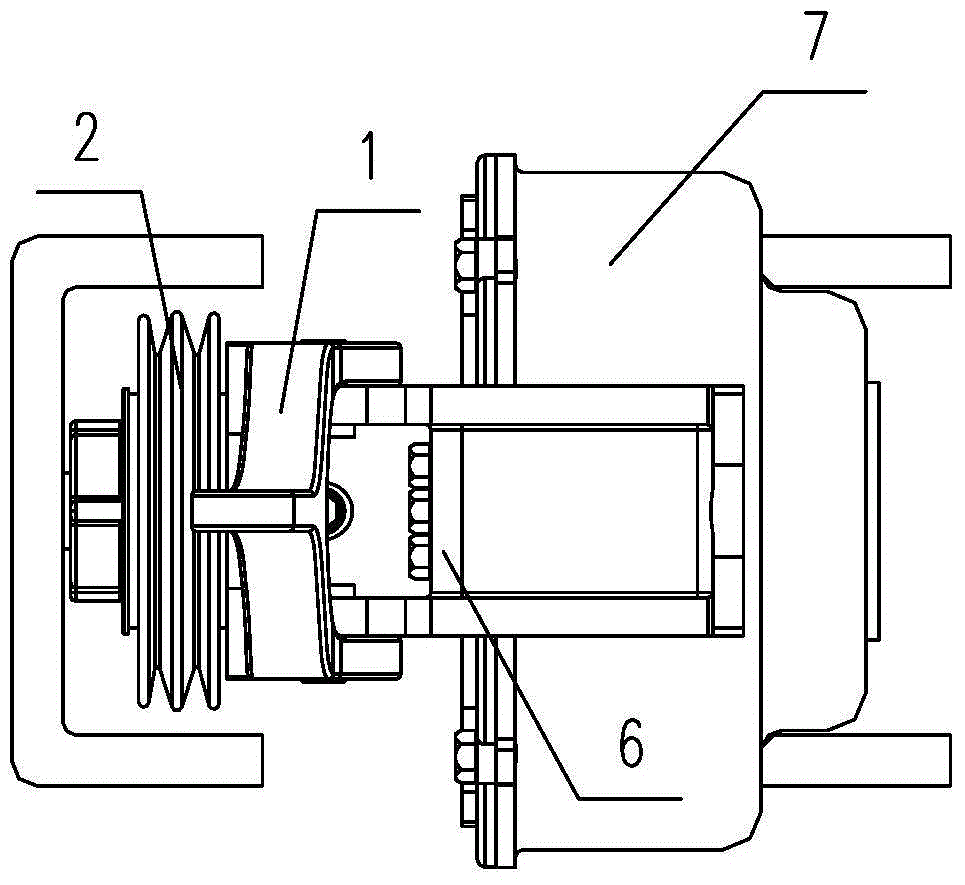

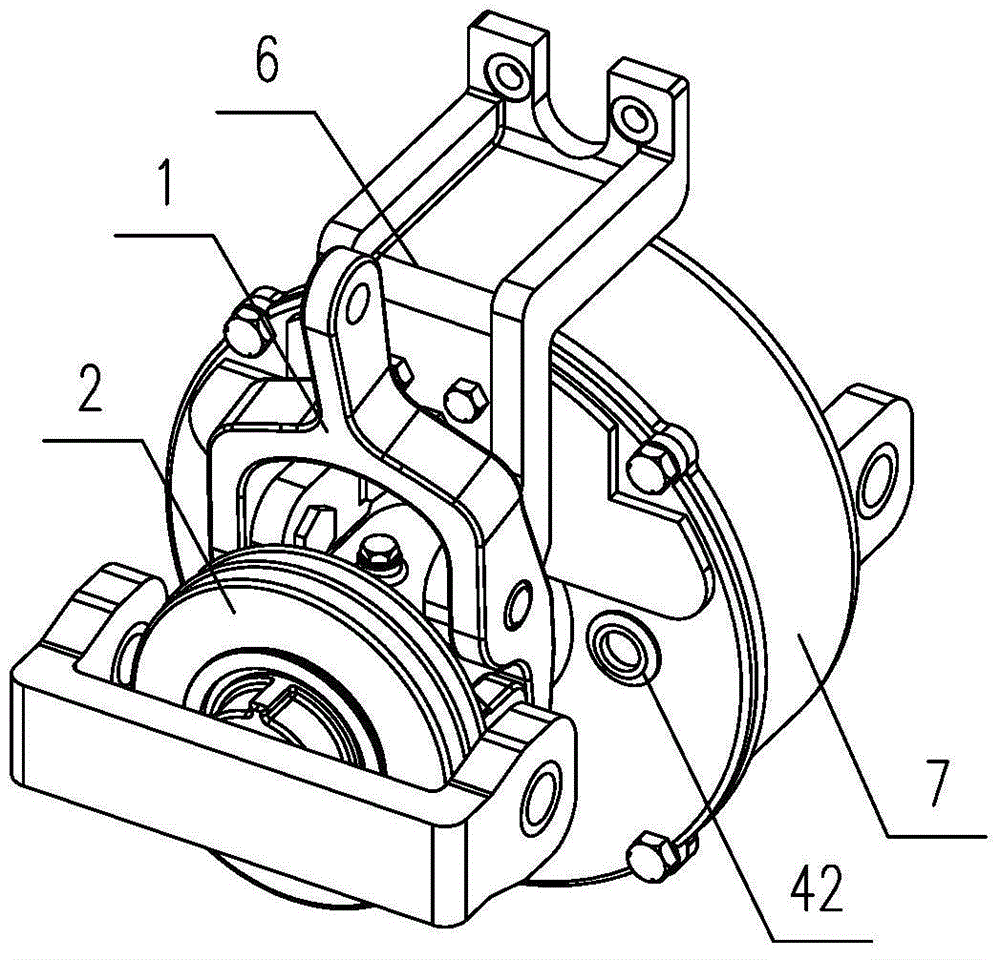

[0052] The unit brake cylinder with hand brake device as shown in the figure includes an integral diaphragm 9, a piston component 10, a cylinder body component 7, a cylinder head component 6, a gasket 13, a sealing ring 11, a relief spring 8, and a hand brake Moving lever 1, push iron 4, dust cover 2, one-way automatic adjustment device for brake disc clearance 12, manual adjustment device for brake disc clearance 3;

[0053] The integral diaphragm 9 is sleeved on the piston composition 10, and a support ring 15 embedded with a lubricating sleeve 14 is provided between the integral diaphragm 9 and the piston composition 10, and placed together in the cylinder composition 7 Inside;

[0054] Described piston composition 10 is welded by piston 19 and piston rod 20, and described piston rod 20 middle part is provided with two screw holes 20a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com