Speed regulating type hydraulic coupling

A technology of hydraulic coupling and coupling, which is applied in the direction of fluid transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of many connection points of working oil pipes, leakage of working oil, waste of energy, etc., and achieve short working time. , reduce leakage points, reduce the effect of pipeline connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the present invention more obvious and easy to understand, a preferred embodiment is described in detail as follows in conjunction with the accompanying drawings.

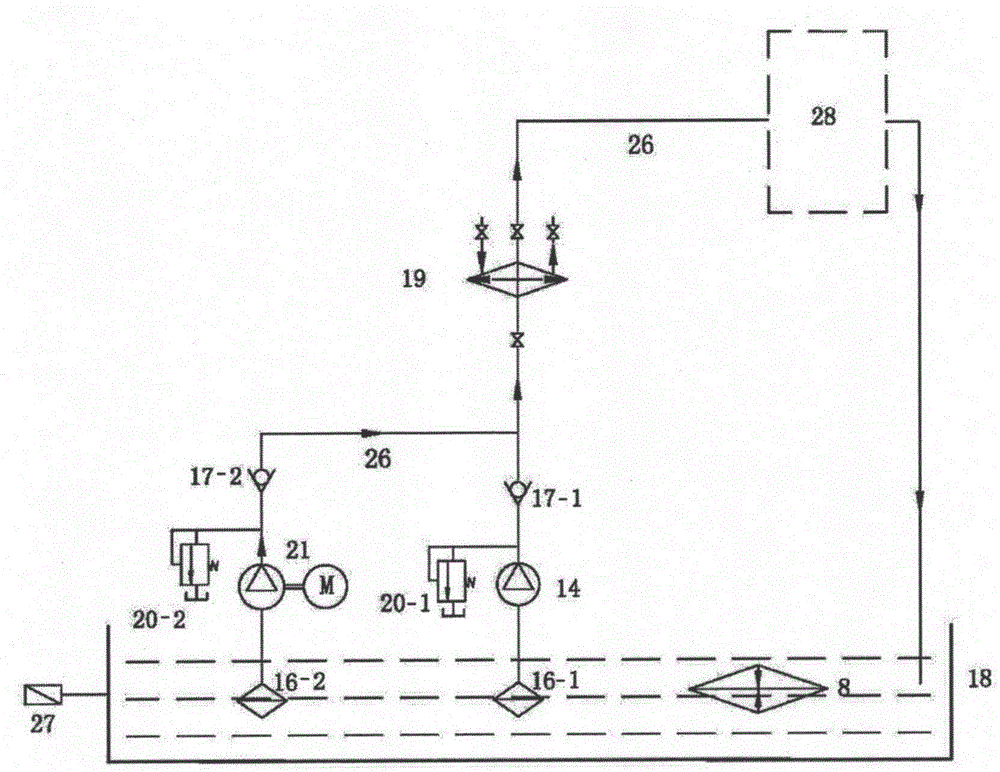

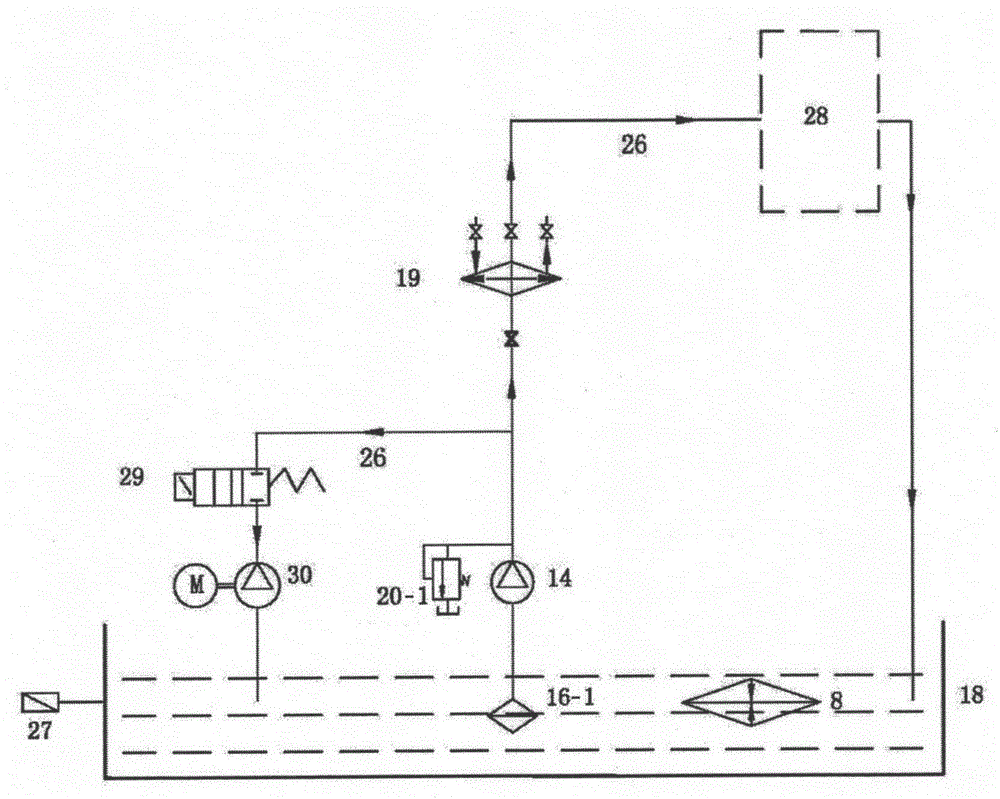

[0030] In the speed-regulating hydraulic coupling provided by the present invention, the originally configured circulating oil pump 21 is changed to an oil suction pump 30, and the second oil filter 16-2, the first check valve 17-1, and the second check valve 17- 2 and the second relief valve 20-2, add a two-position two-way electromagnetic reversing valve 29, one end of the two-position two-way electromagnetic reversing valve 29 is connected to the oil suction pump 30 through a pipeline, and the other end is connected to the cooler through a pipeline 19. Form a new speed-regulating hydraulic coupling, such as image 3 shown. Compared with the original circulating oil pump 21, the displacement of the oil suction pump 30 is reduced, and the oil flow direction is changed. The oil pump 30 suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com