Special check valve for pneumatic material conveying

A check valve and material technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve the problems of dust sticking, check valve leakage, loose closing, etc., achieve long service life, good sealing, avoid The effect of jam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

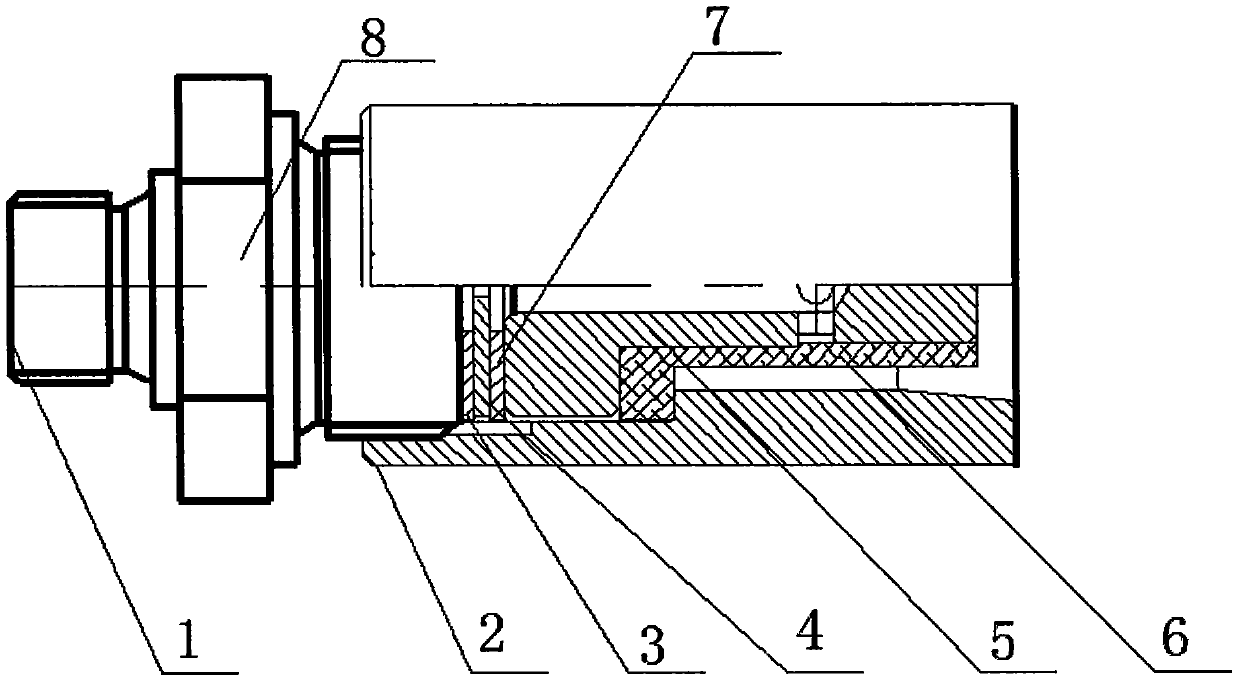

[0017] see figure 1 , special check valve for pneumatic material conveying system, including gland 1, valve body 2, gasket 1 3, gasket 2 4, valve core 5, sealing sleeve 6; gland 1 and valve body 2 are connected by threads, The two are tightly engaged to ensure that the valve will not let the medium leak out through the valve stem, and ensure that the valve achieves zero leakage within the design pressure range; the valve body 2 is made of wear-resistant metal material, and the valve body 2 is equipped with Valve core 5, sealing sleeve 6, gasket one 3, gasket two 4; valve core 5 is divided into a valve head and a valve stem, the valve stem is provided with a cavity in the axial direction, and 4 holes of the same size are opened in the radial dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com