Down lamp

A technology of downlights and cooling tubes, which is applied to point light sources, lighting and heating equipment, fixed lighting devices, etc., can solve the problems of troublesome installation and disassembly, unsatisfactory heat dissipation effect, etc., to achieve convenient installation and disassembly, improve heat dissipation effect, The effect of shrinking the volume

Active Publication Date: 2015-11-18

邳州市城洁保洁有限公司

View PDF6 Cites 52 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The existing radiators used for downlights are generally fixed in shape due to design defects. In order to increase the heat dissipation area, heat dissipation fins are generally densely distributed on the outer wall of the downlight, but the heat is concentrated on the outer wall of the downlight during the heat dissipation process. , the cooling effect is not ideal

Moreover, the existing downlight must be fixed by a snap ring, which is troublesome to install and disassemble.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

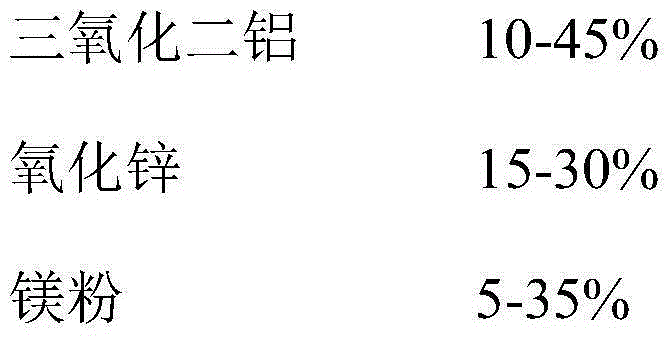

[0036] The foamed aluminum alloy material of the present invention consists of the following components by weight percentage:

[0037]

Embodiment 2

[0039] The foamed aluminum alloy material of the present invention consists of the following components by weight percentage:

[0040]

Embodiment 3

[0042] The foamed aluminum alloy material of the present invention consists of the following components by weight percentage:

[0043]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

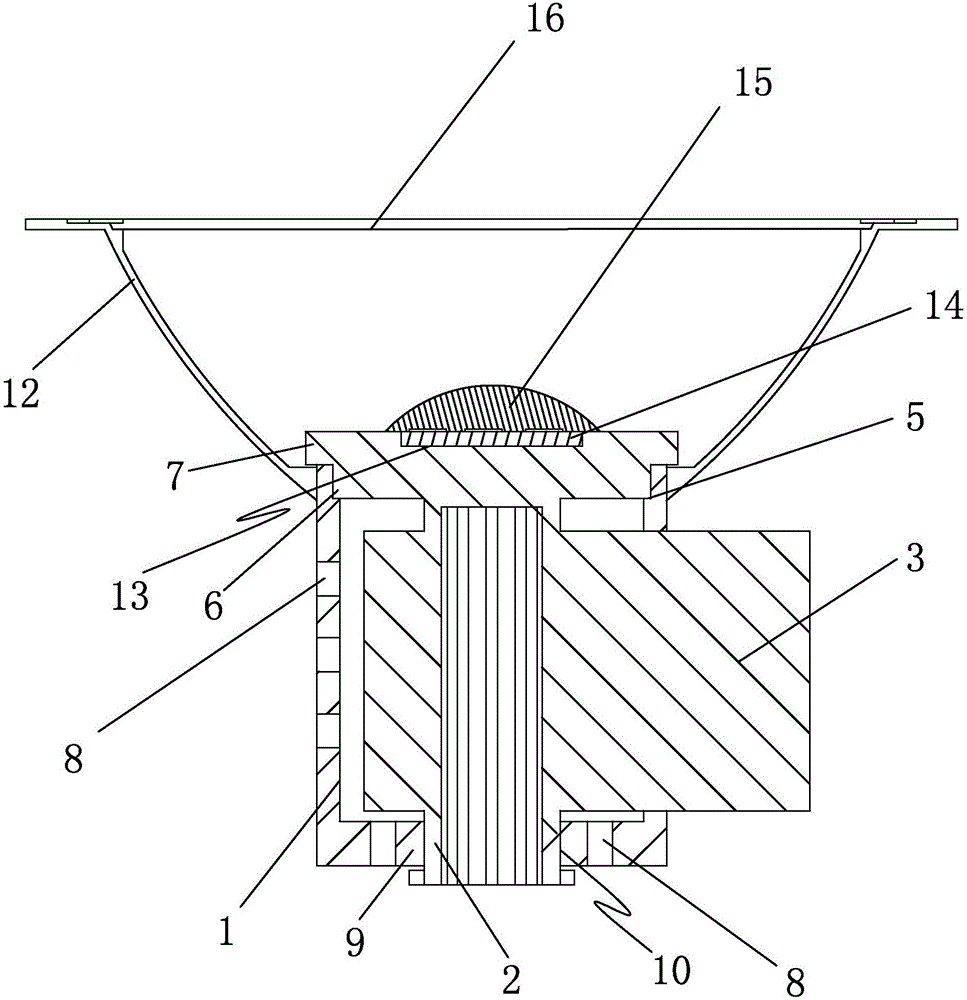

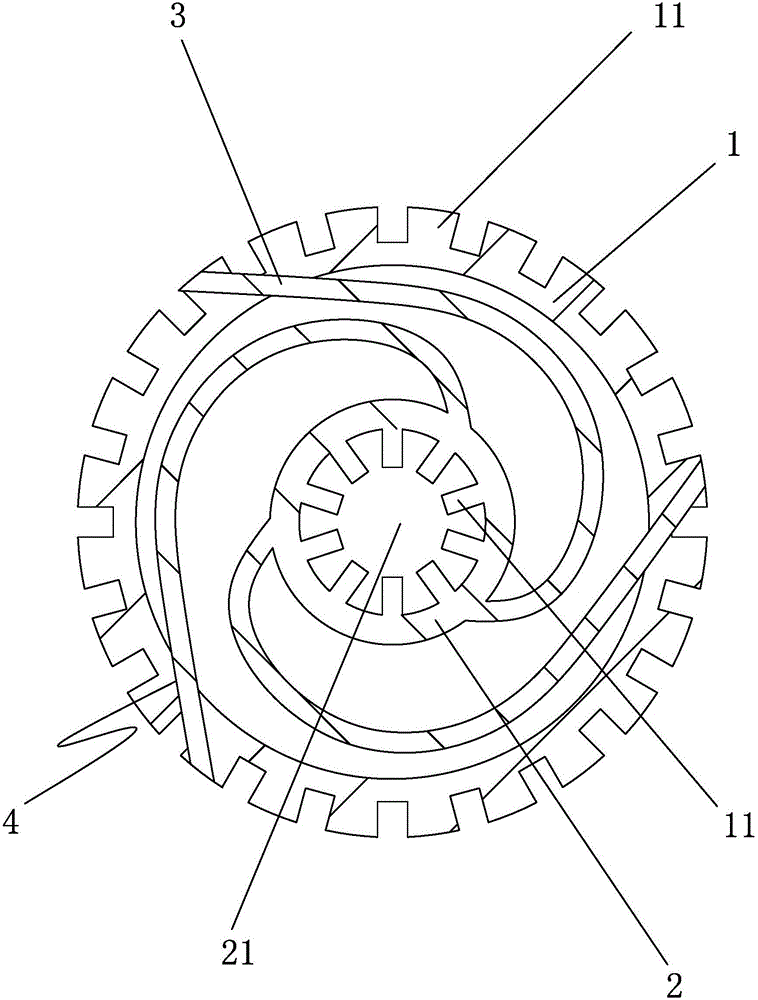

The invention discloses a down lamp. The down lamp is characterized in that the down lamp comprises a heat radiation cylinder body; a reflecting cover is connected with the upper end of the heat radiation cylinder body; a plurality of heat radiation fins are arranged on the outer wall of the heat radiation cylinder body; a heat radiator main body capable of rotating relative to the heat radiation cylinder body is arranged in the heat radiation cylinder body; a cavity is arranged in the heat radiator main body; heat radiation fins are distributed on the inner wall of the heat radiator main body evenly; a plurality of heat radiation sheets capable of huddling up on the heat radiator main body are arranged on the outer wall of the heat radiator main body; a plurality of guide grooves are formed in the heat radiation cylinder body; the heat radiation sheets are arranged in the guide grooves; an installing groove is formed in the upper end portion of the heat radiator main body; an LED chip is arranged in the installing groove. According to the down lamp, shortcomings in the prior art are overcome; the down lamp is simple in structure; a heat radiator can be unfolded, so that the down lamp is good in heat radiation effect and convenient to assemble and disassemble.

Description

technical field [0001] The invention relates to a downlight. Background technique [0002] The existing radiators used for downlights are generally fixed in shape due to design defects. In order to increase the heat dissipation area, heat dissipation fins are generally densely distributed on the outer wall of the downlight, but the heat is concentrated on the outer wall of the downlight during the heat dissipation process. , the heat dissipation effect is not ideal. Moreover, the existing downlights must be fixed by snap springs, and installation and disassembly are cumbersome. [0003] Therefore existing downlight needs to be further perfected. Contents of the invention [0004] The purpose of the present invention is to overcome the disadvantages of the prior art, and provide a downlight with simple structure, a radiator that can be deployed, a good heat dissipation effect, and convenient installation and disassembly. [0005] In order to achieve the above object, the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F21S8/00F21V29/77F21V29/89F21V29/83F21Y101/02

CPCF21S8/00

Inventor 黄亚宾

Owner 邳州市城洁保洁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com