Wood veneer drying device

A technology of wood veneer and drying device, which is applied in drying gas arrangement, progressive dryer, drying of solid materials, etc., can solve the problems of veneer curling and uneven shrinkage of veneer, and achieve the effect of reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below through specific implementations:

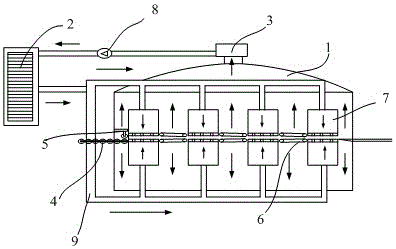

[0013] The reference signs in the drawings of the specification include: drying room 1, hot air blower 2, steam-water separator 3, feed roller 4, pressure roller 5, conveyor belt 6, hot air box 7, fan 8, and air inlet pipe 9.

[0014] The embodiment is basically as attached figure 1 Shown: The wood veneer drying device in this scheme is divided into a drying room 1, a drying mechanism and a board transport mechanism. The drying mechanism includes a hot air box 7, an air inlet pipe 9 and a hot air blower 2. The hot air box 7 is arranged up and down. A hot air box group is formed. The middle part of the hot air box group forms a transportation channel for wood veneers. The two oppositely arranged hot air boxes 7 are equipped with multiple jet pipes at the ends. The air used for drying first passes through the fan 8 to transfer the drying room 1 The air in the air is drawn out t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com