A kind of pulsating heat pipe heat exchanger and its processing method

A technology of pulsating heat pipes and processing methods, which is applied to indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of hidden dangers in the safe operation of heat exchange systems, mixing of hot and cold fluids, long processing cycles, etc., and achieve easy large-scale Batch processing and production, simple processing technology and low quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

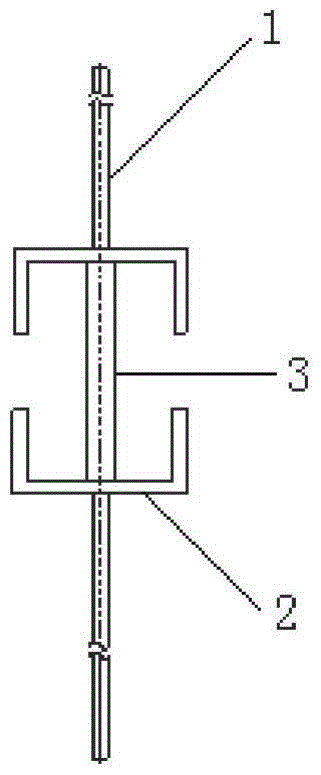

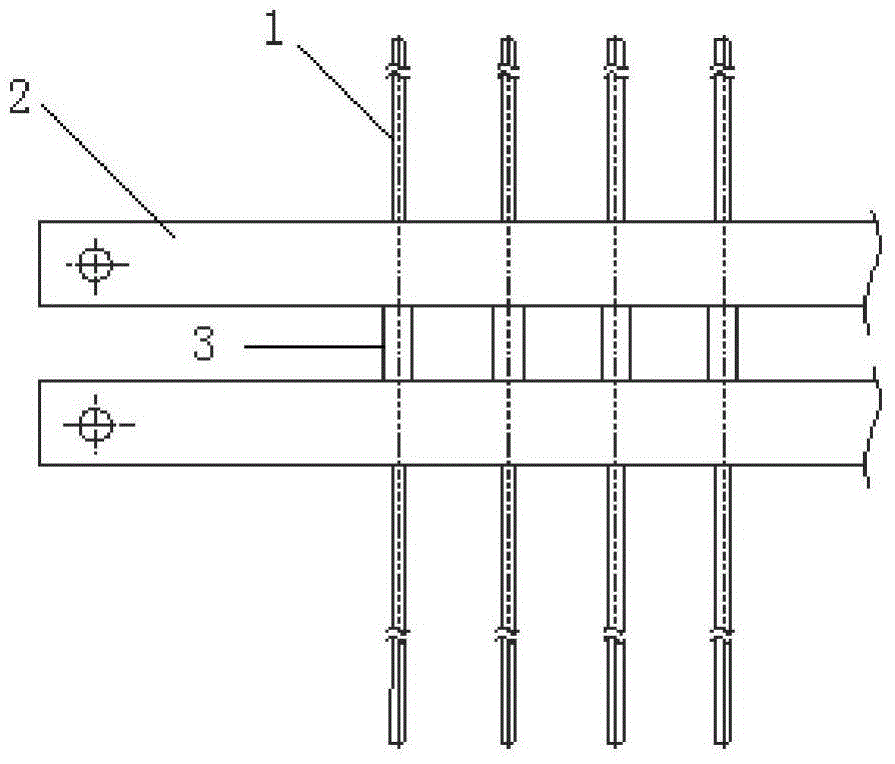

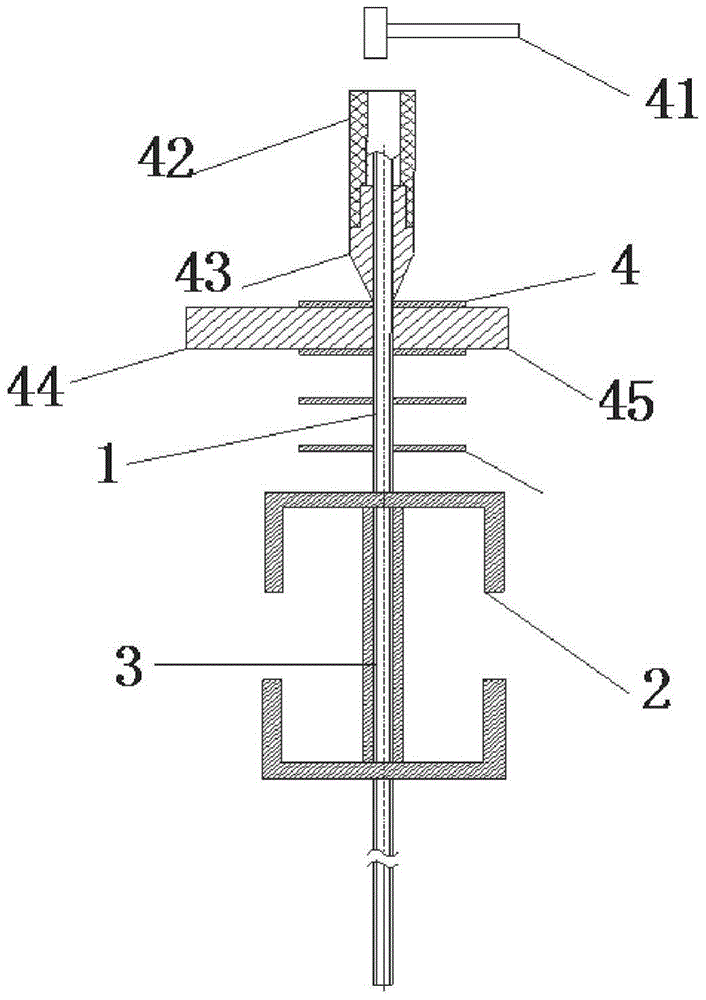

[0054] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0055] Before processing, it is first necessary to carry out the processing of each component (take a certain set of actual component parameters in the project as an example):

[0056] a. Vertical heat exchange branch pipe 1:

[0057] Cut out 42 cold-drawn copper tubes with an outer diameter of 3mm, an inner diameter of 2mm, and a length of 400mm, each of which is a group of 7, a total of 6 groups. Since the vertical heat exchange branch pipe 1 is in direct contact with the hot and cold fluids, and both the hot and cold fluids are pressurized fluids, the vertical heat exchange branch pipe 1 is made of cold-drawn copper tubes with high strength, large pressure bearing and not easily deformed.

[0058] b. Partition 2:

[0059] A steel plate with a thickness of 3mm and a U-shaped cross-section. In the structure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com