Device and process for continuously preparing methanol emulsified diesel fuel

A technology for emulsifying diesel oil and methanol, which is applied in the petroleum industry, chemical instruments and methods, liquid carbon-containing fuels, etc., and can solve problems such as unsatisfactory mixing effects, large differences in volume flow ratio, and unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

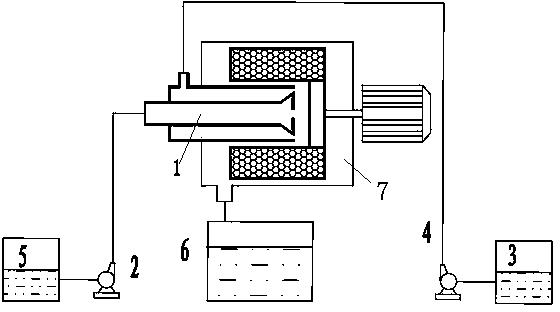

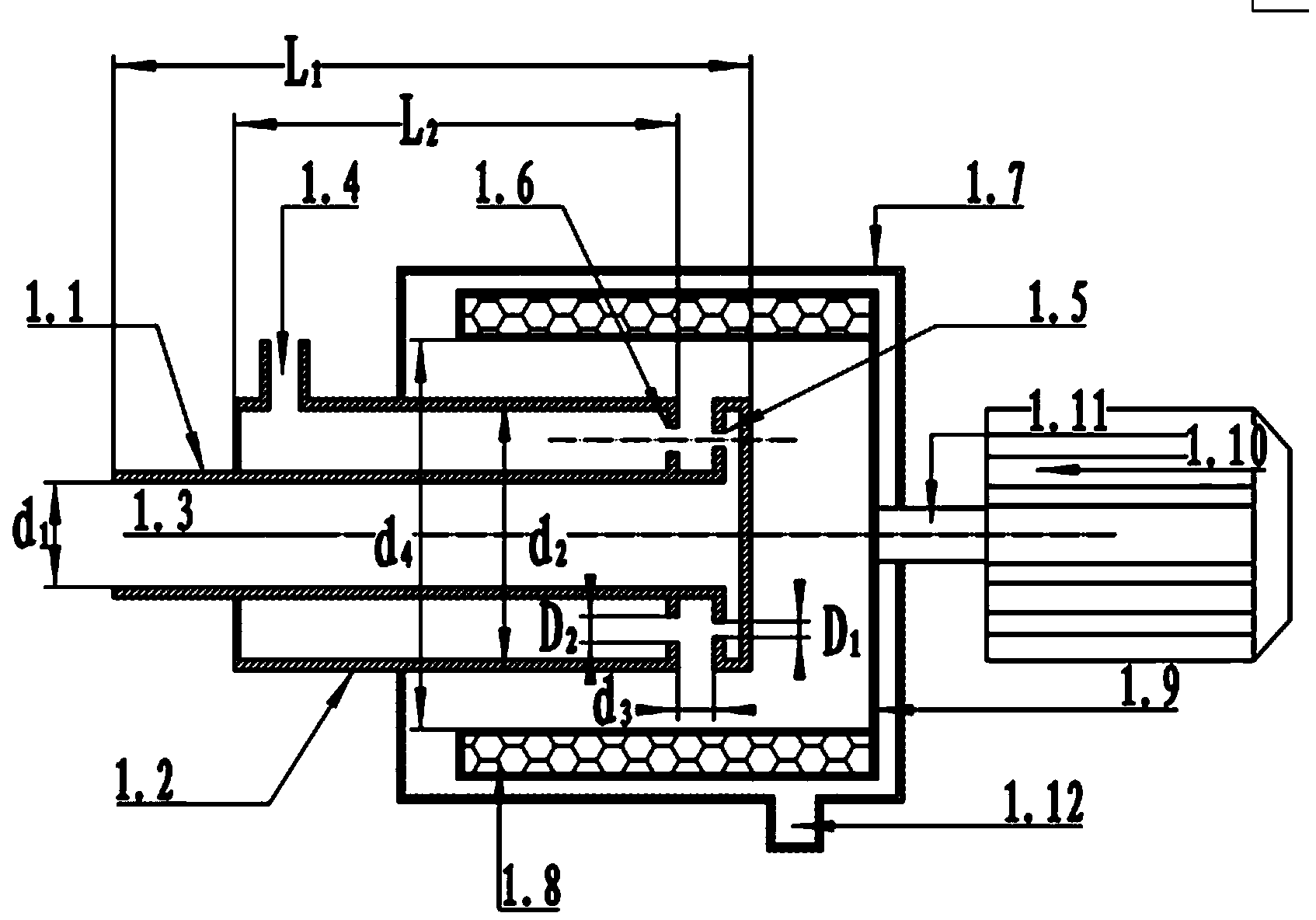

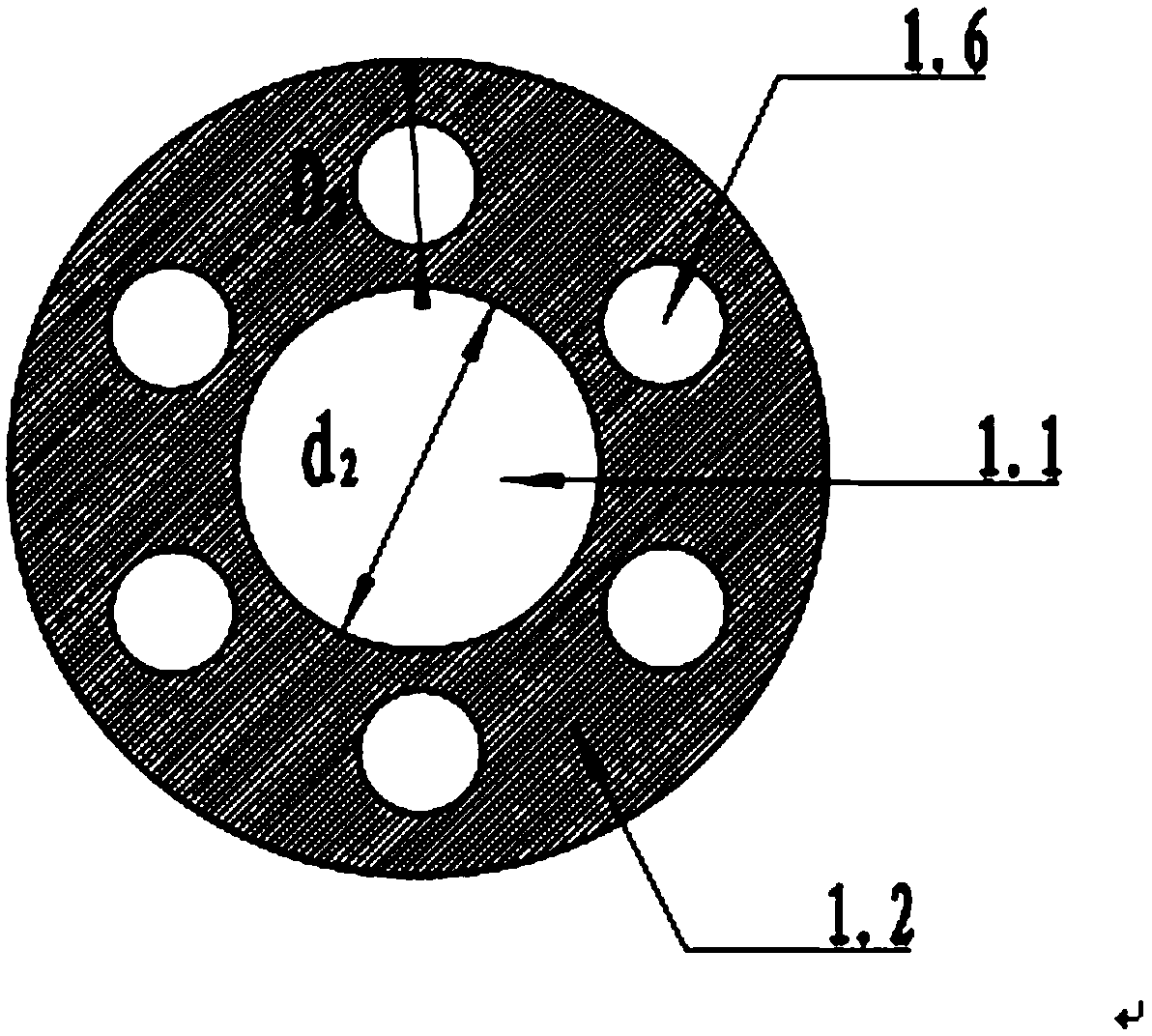

[0027] Prepare the water phase with hydrophilic emulsifier in the methanol storage tank and the oil phase with lipophilic emulsifier in the diesel storage tank. Prepare 40 tons / h of methanol diesel emulsion, according to the ratio of water phase: oil phase = 10:90, enter the new impinging flow-rotating packed bed emulsification device, adopt the new impinging flow-rotating packed bed device. The structural dimensions and characteristics are: main The discharge holes of the inlet (diesel) material pipe and the discharge holes of the casing are several holes whose centers are located on the same circumference and which are evenly distributed relative to the center circumference of the pipe axis, forming annular holes respectively. Main feed pipe diameter d 1 and main feed pipe discharge hole diameter D 1 The ratio is 2; casing diameter d 2 and main feed pipe diameter d 1 The ratio is 2; the main feed pipe length L 1 and main feed pipe diameter d 1 The ratio is 20; sleeve le...

Embodiment 2

[0029] Prepare the water phase with hydrophilic emulsifier in the methanol storage tank and the oil phase with lipophilic emulsifier in the diesel storage tank. Prepare 5 tons / h of methanol diesel emulsion, and enter the new impinging flow-rotating packed bed emulsification device at the ratio of water phase: oil phase = 30:70. The characteristic dimensions and characteristics of the new impinging flow-rotating packed bed device are: The discharge hole of the main inlet (diesel) material pipe and the discharge hole of the casing are a number of holes whose centers are located on the same circumference and are evenly distributed relative to the center circumference of the pipe axis, forming ring holes respectively. Main feed pipe diameter d 1 and main feed pipe discharge hole diameter D 1 The ratio is 25; casing diameter d 2 and main feed pipe diameter d 1 The ratio is 5; the main feed pipe length L 1 and main feed pipe diameter d 1 The ratio is 10; the sleeve length L 2 ...

Embodiment 3

[0031] Prepare the water phase with hydrophilic emulsifier in the methanol storage tank and the oil phase with lipophilic emulsifier in the diesel storage tank. Prepare 10 tons / h of methanol diesel emulsion, and enter the new impinging flow-rotating packed bed emulsification device at the ratio of water phase: oil phase = 20:80. The characteristic dimensions and characteristics of the new impinging flow-rotating packed bed device are: The discharge hole of the main inlet (diesel) material pipe and the discharge hole of the casing are a number of holes whose centers are located on the same circumference and are evenly distributed relative to the center circumference of the pipe axis, forming ring holes respectively. Main feed pipe diameter d 1 and main feed pipe discharge hole diameter D 1 The ratio is 50; casing diameter d 2 and main feed pipe diameter d 1 The ratio is 1; the main feed pipe length L 1 and main feed pipe diameter d 1 The ratio is 15; the sleeve length L 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com