Large external-driven integral horizontal rotary continuous biogas dry fermentation device and method thereof

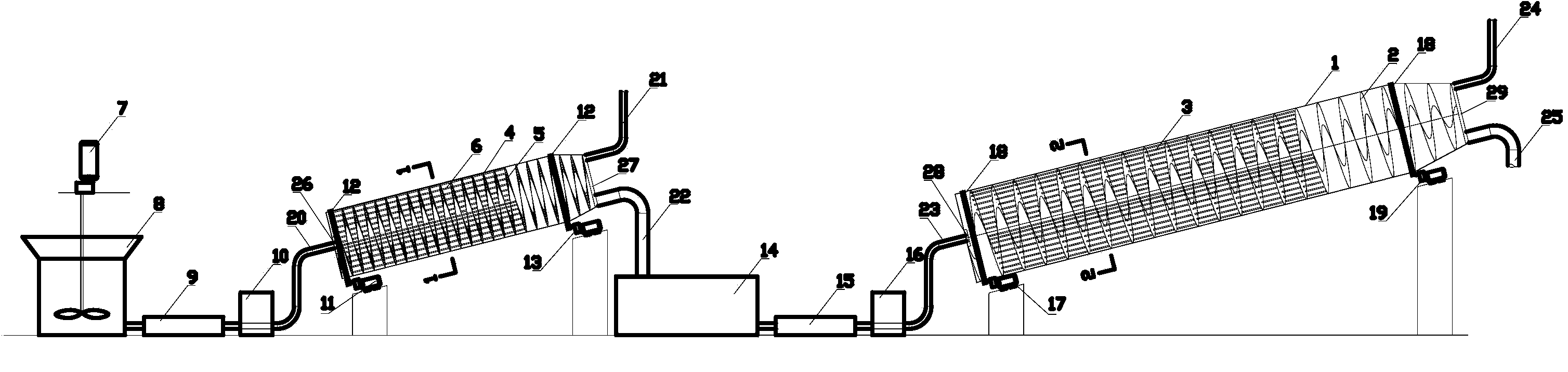

An externally driven, horizontal technology, used in fermentation, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the problems of uneven mixing of materials, high dry matter content of materials, and incomplete fermentation of materials discharged from the warehouse. The overall stirring is uniform, the fermentation is thorough, and the effect of mixing and mixing power is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Cabin

[0029] The production is made of stainless steel, and the effective volume of the hydrolysis fermentation cabin is 3.0m 3 , the effective volume of the methane fermentation cabin is 10m 3 . The angle between the fermentation cabin and the horizontal plane is 14°.

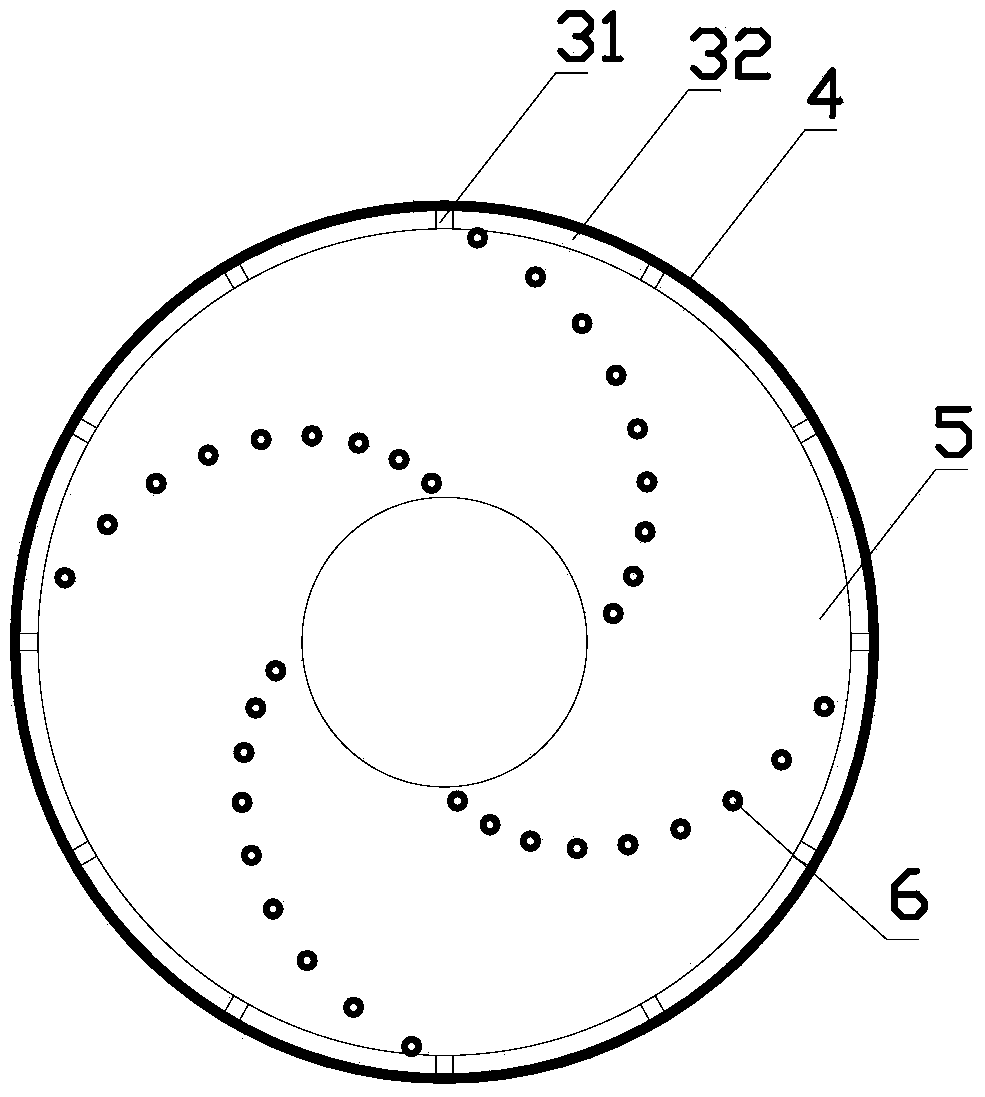

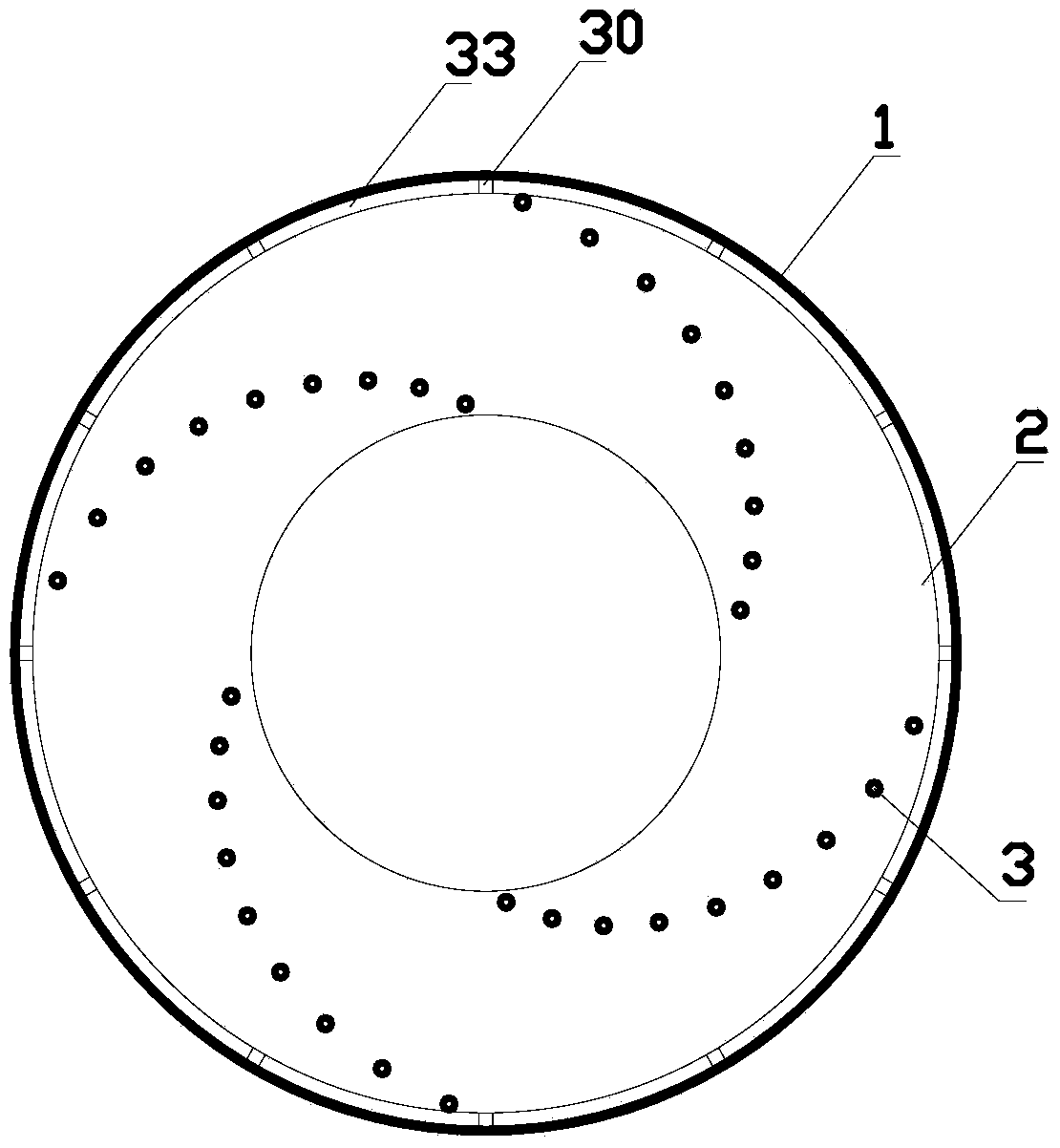

[0030] 2. Main screw and attached fins

[0031] For hydrolysis fermentation, the pitch of the main spiral fins is 200mm, with additional transverse fins, the length of which is 200mm, and only in the last 1 / 5 area of the hydrolysis acidification reaction chamber without additional transverse fins; for methane fermentation, the pitch of the main spiral fins is 400mm, with additional Small transverse fins, the length of the transverse fins is 400mm, and no transverse small fins are installed in the last 1 / 3 area of the methane fermentation tank.

[0032] 3. Volume of fermentation chamber

[0033] The diameter of the hydrolysis fermentation cabin is 1.2m, the length is 4.0m, and the overall v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com