A horizontal large-scale continuous biogas dry fermentation device and method

A dry fermentation, large-scale technology, applied in fermentation, biochemical cleaning devices, biochemical equipment and methods, etc., can solve problems such as the realization of large volume of unmixed displacement fermentation manifests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

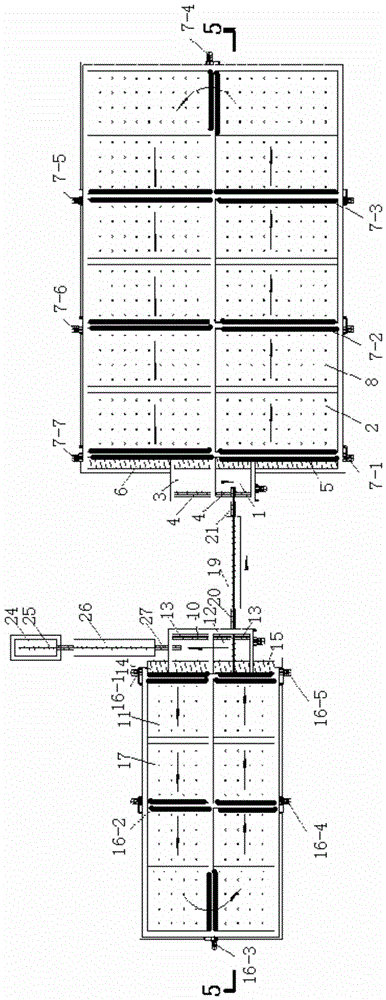

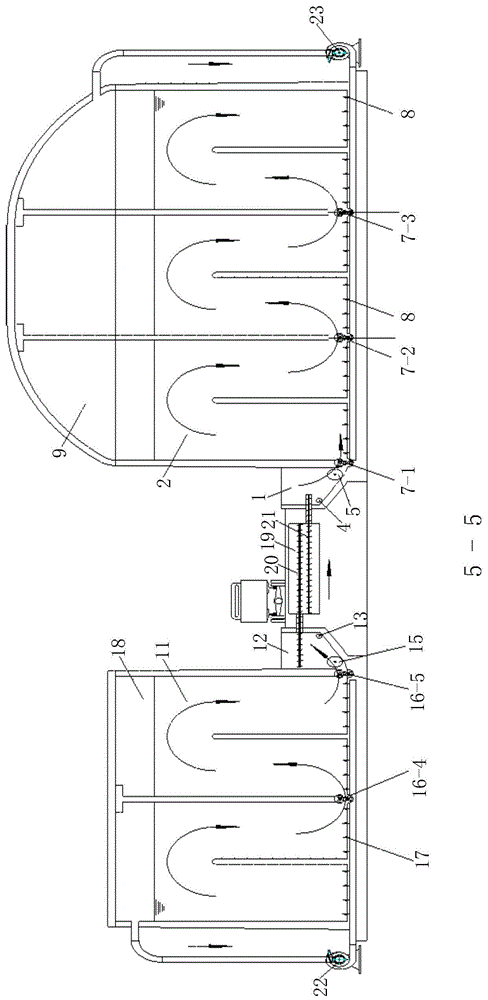

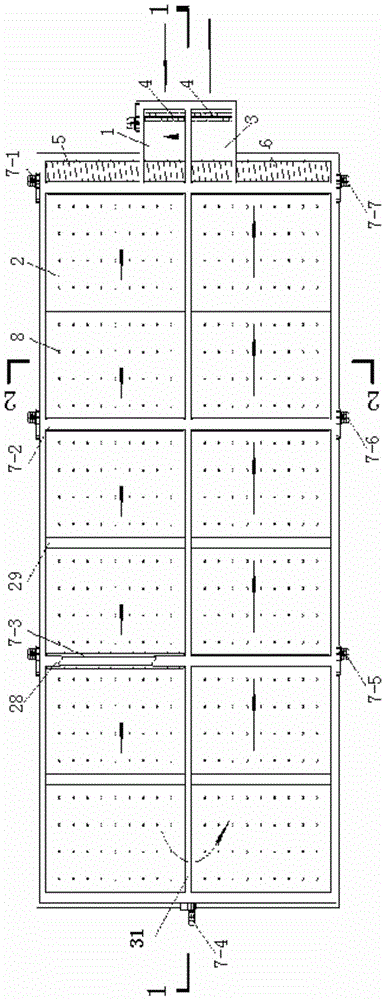

[0059] 1. Cabin

[0060] The production adopts reinforced concrete structure, and the effective volume of the hydrolysis fermentation cabin is 1500m 3 , the effective volume of the methane fermentation cabin is 5000m 3 .

[0061] 2. Stir

[0062] One of the key issues in dry fermentation of mixed materials is agitation. The agitation in this design is pneumatic agitation to collect the gas produced by fermentation (hydrolysis is hydrolysis waste gas, and methane fermentation is the mixed gas of methane fermentation). Since the overall fermentation material filling height of this process design is significantly lower than other dry fermentations, Therefore, it is realized that the stirring gas pressurizing device can adopt the form of a general-purpose fan, which reduces the engineering cost and improves the system stability, and the stirring uniformity is also enhanced.

[0063] 3. Thruster

[0064] This design adopts two-wing transverse propeller design under the conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com