Multichannel numerical control machine tool energy consumption data acquisition bench

A technology of numerical control machine tools and energy consumption data, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of machine tool data collection limitations, low sampling frequency, and inconvenient operation, and achieve the effect of expanding data types, speeding up collection speed, and simple use process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

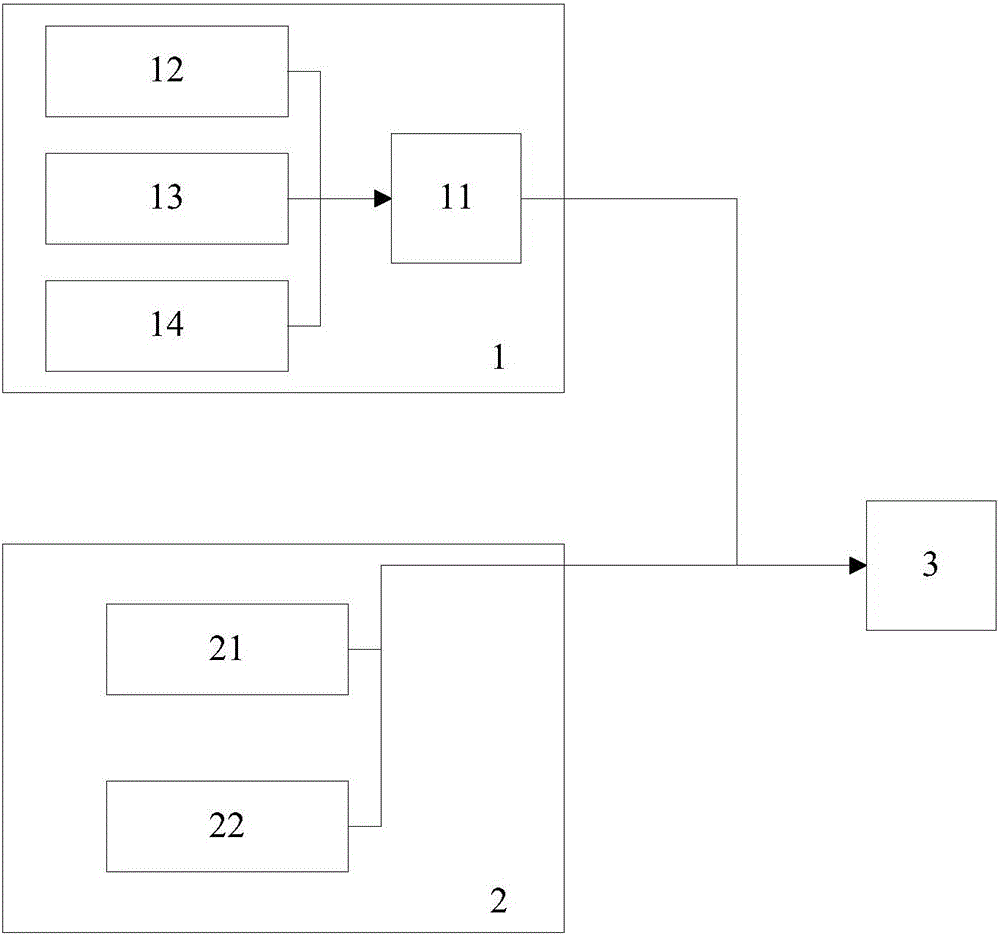

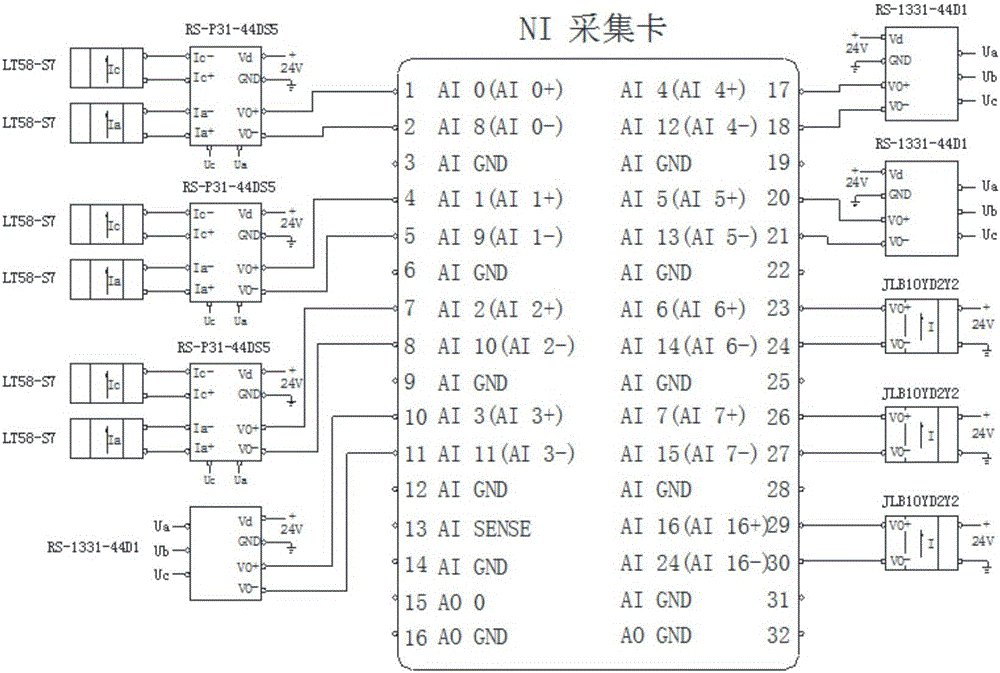

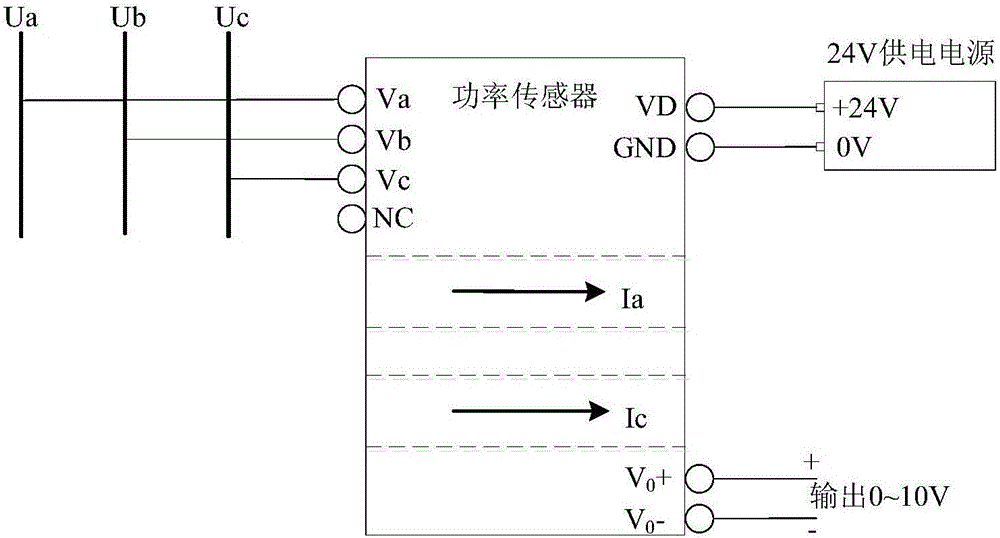

[0030] Such as Figure 1-2 As shown, a multi-channel machine tool energy consumption data acquisition bench, the acquisition bench system hardware mainly includes: LabVIEW acquisition module 1, SERVOGUIDE acquisition module 2 and industrial PC 3. The LabVIEW acquisition module includes a NI data acquisition card 11 , a power sensor 12 , a voltage sensor 13 , and a current sensor 14 , and the SERVOGUIDE acquisition module 2 includes a torque sensor 21 and a rotational speed sensor 22 . In addition, the stand also includes a power line filter, 220V to 24V switching power supply and 220V to 5V switching power supply.

[0031] (2) Further description of structural features

[0032] The NI data acquisition card 11 adopts the X series NIUSB6342 multi-function data acquisition card launched by NI Company, which can be directly connected to the PC through the USB interface and is easy to use.

[0033] The 220V to 24V switching power supply is used to supply power to the power sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com