Non-contact measuring system and method for drainage pipeline fluid flow

A drainage pipeline and measurement method technology, which is applied in the direction of liquid/fluid solid measurement, measurement flow/mass flow, measurement device, etc., can solve the failure, and the operator has to take out the equipment and clean it before reinstalling it at the bottom of the pipeline to measure Reduced precision, dangerous installation and operation of drainage pipes, etc., achieve the effect of light size, low overall power consumption, and reduced construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical content disclosed in this application more detailed and complete, reference may be made to the drawings and the following various specific embodiments of the present invention, and the same symbols in the drawings represent the same or similar components. However, those skilled in the art should understand that the examples provided below are not intended to limit the scope of the present invention. In addition, the drawings are only for schematic illustration and are not drawn according to their original scale.

[0035] The specific implementation manners of various aspects of the present invention will be further described in detail below with reference to the accompanying drawings.

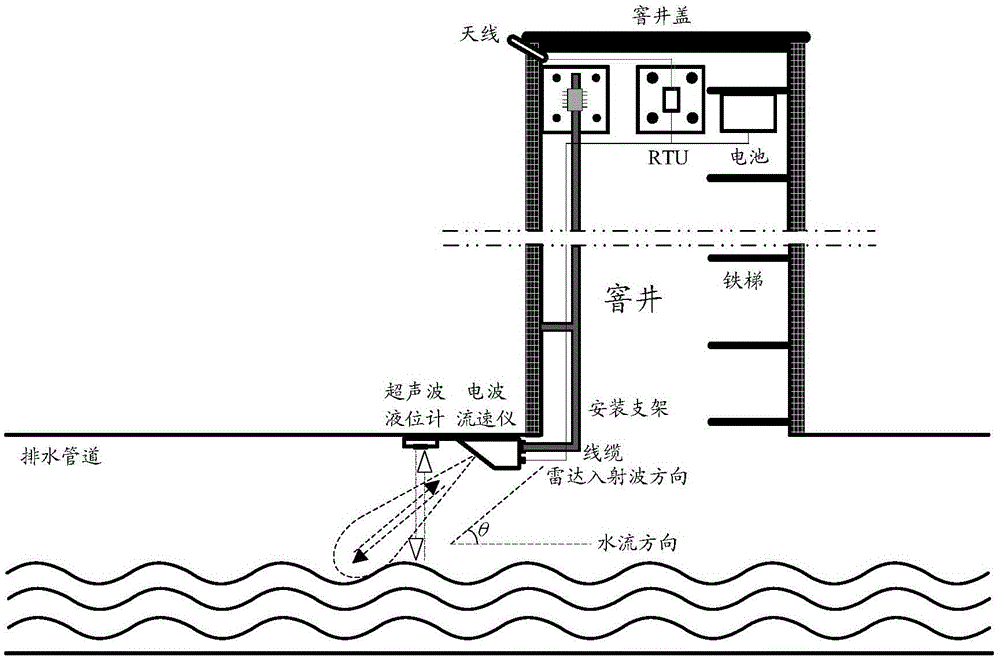

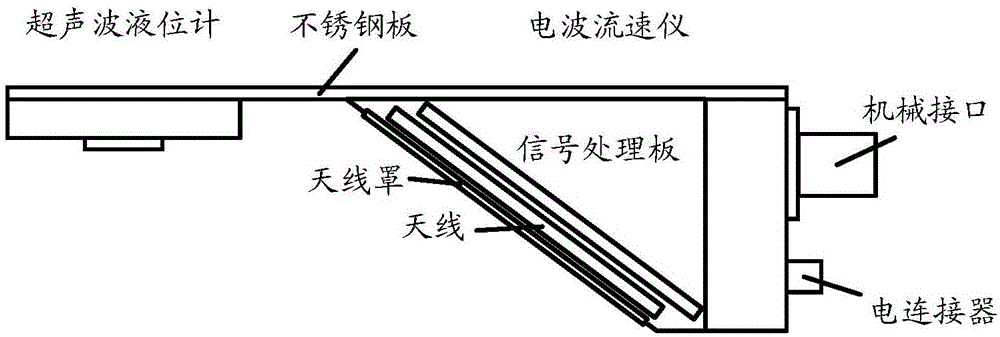

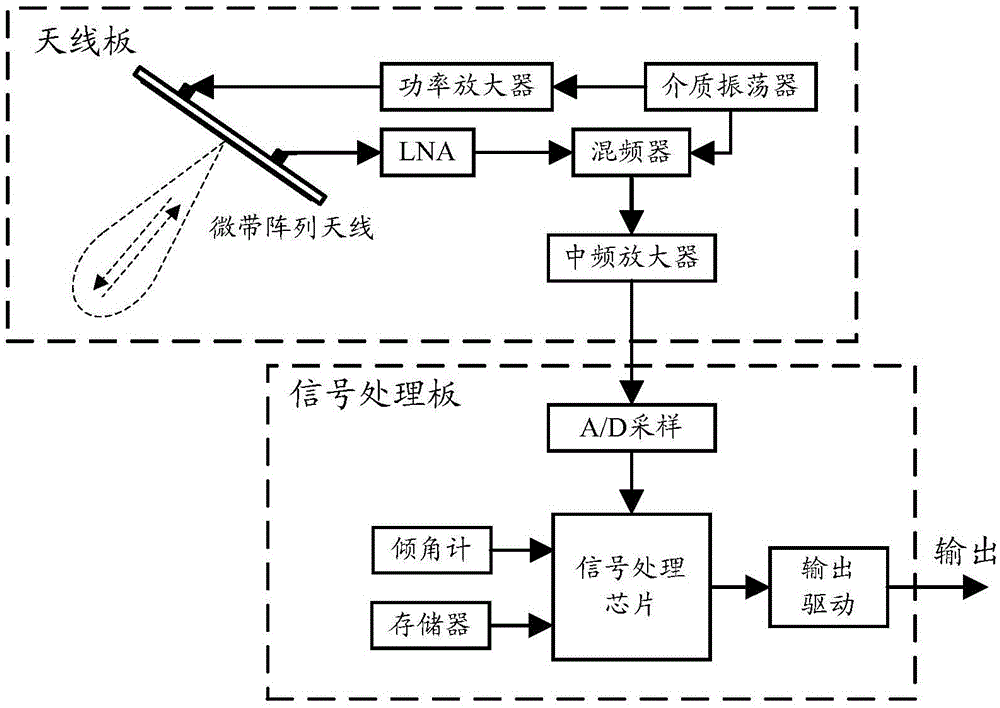

[0036] figure 1 A schematic diagram showing the application scene of the non-contact drainage pipe fluid flow measurement system of the present invention. figure 2 Shows figure 1 Schematic diagram of the structure of the measuring system of the electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com