Dynamic induction simulation device for broken surrounding rock grouting reinforcement, and testing method therefor

A technique of grouting reinforcement and crushing of surrounding rocks, which is applied in fluid dynamics tests, measuring devices, testing of machines/structural components, etc. It can solve problems such as unpublished simulations, large size requirements for test pieces, and difficult pressure control, etc., to achieve The effect of improving test efficiency, overcoming detection problems, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

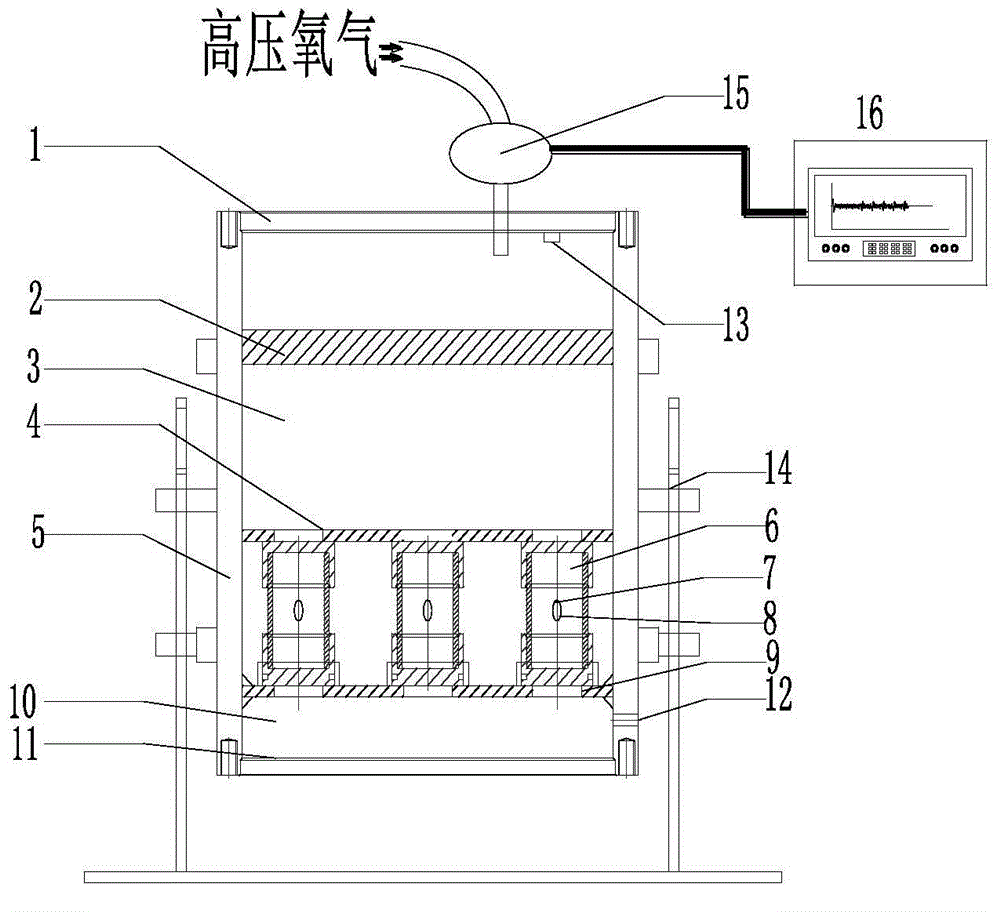

[0046] A dynamic induction simulation device for grouting reinforcement of broken surrounding rock is composed of a test piece mold 6, a grouting container 24, a high-pressure oxygen pressurizer, a sensing device, a dynamic monitoring and control system and other main parts.

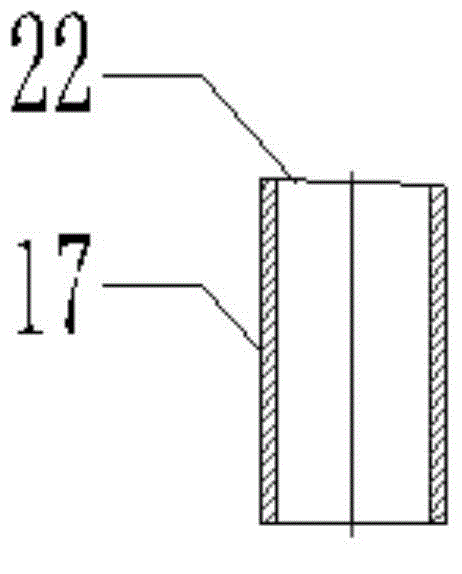

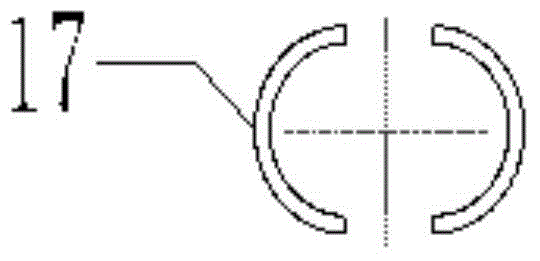

[0047] The material of the test piece mold 6 is tempered glass, so as to facilitate the visual observation of the slurry diffusion. The test piece mold side wall 17 is divided into two halves by a drum. When the test piece is solidified and cured, it can be conveniently disassembled and taken out. The contact surface between the upper cover 18 of the test piece mold and the lower cover 19 of the test piece mold and the mold body is a slope 22, and the outside of the upper and lower covers is provided with a slot 23 for convenient wrench force, which solves the problem that the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com