Battery Cycle Life Prediction Method

A technology for battery cycle and life prediction, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of shortening the life evaluation cycle, large equipment and energy consumption, and long time consumption, so as to shorten the performance evaluation time and predict. The effect of high accuracy, avoiding energy consumption and resource waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

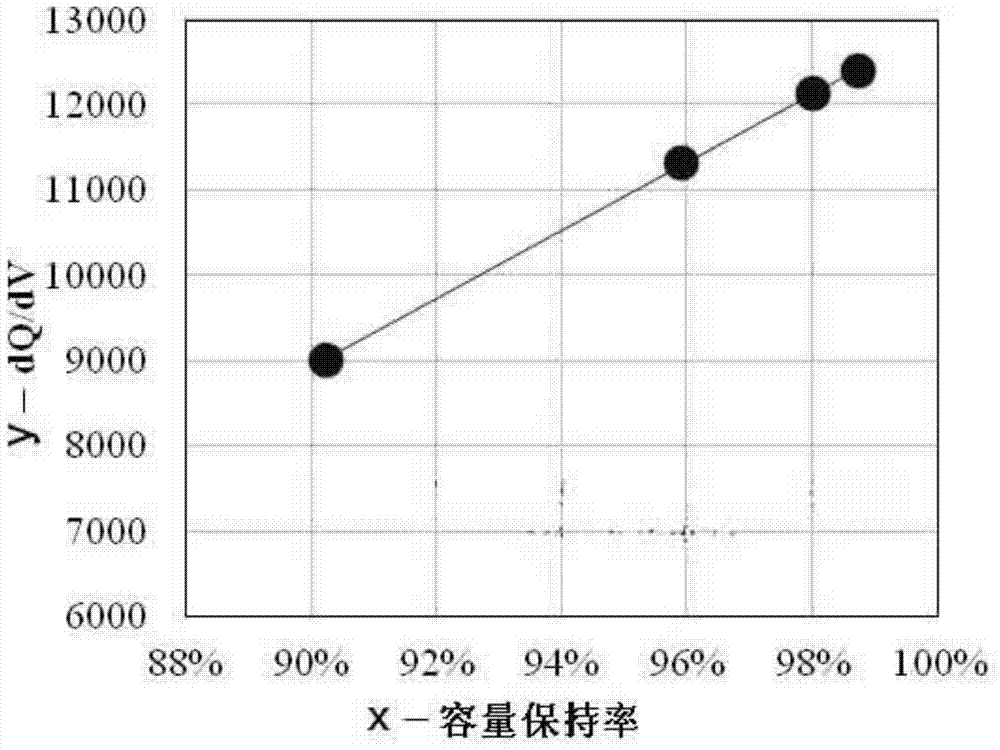

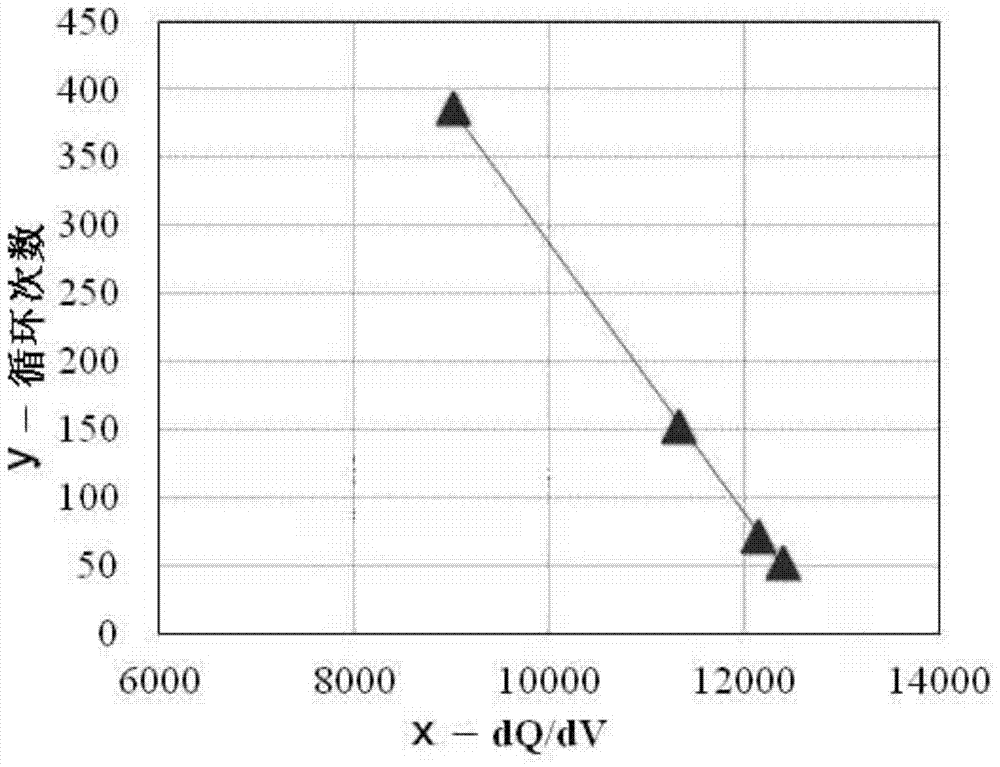

[0024] The following takes the test and evaluation of a lithium-ion battery as an example to describe the present invention in detail, so as to further illustrate the substantive features and remarkable progress of the present invention.

[0025] In this example, the 0.7C charge-discharge cycle life of a 18650 (2200mAh) battery at room temperature is to be investigated, and the test equipment is an Arbin charge-discharge instrument.

[0026] Set the corresponding battery cycle process on the blue battery, firstly conduct a small current charge and discharge test of the battery before cycle, specifically: discharge the battery, the current is 220mA, the cut-off voltage is 3.0V, sleep for 15min; the constant current charging current is 220mA , the cut-off voltage is 4.20V, the constant-voltage charging cut-off current is 44mA, and sleeps for 15 minutes; the constant-current discharge current is 220mA, the cut-off voltage is 3.0V, and sleeps for 15 minutes.

[0027] Then enter th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com