Nuclear power plant waste solidification treatment system and method

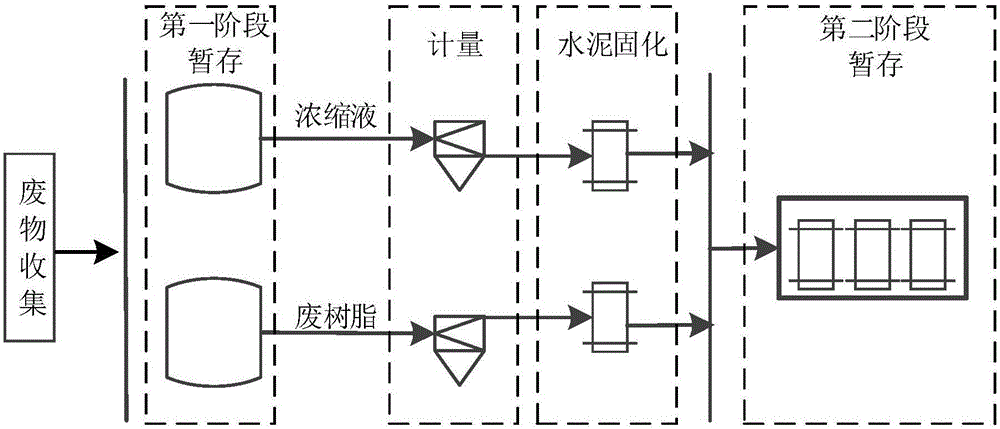

A solidification treatment and nuclear power plant technology, applied in nuclear engineering, radioactive purification, etc., can solve the problems of high complexity of equipment, high installation difficulty, weight deviation of weighing units, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

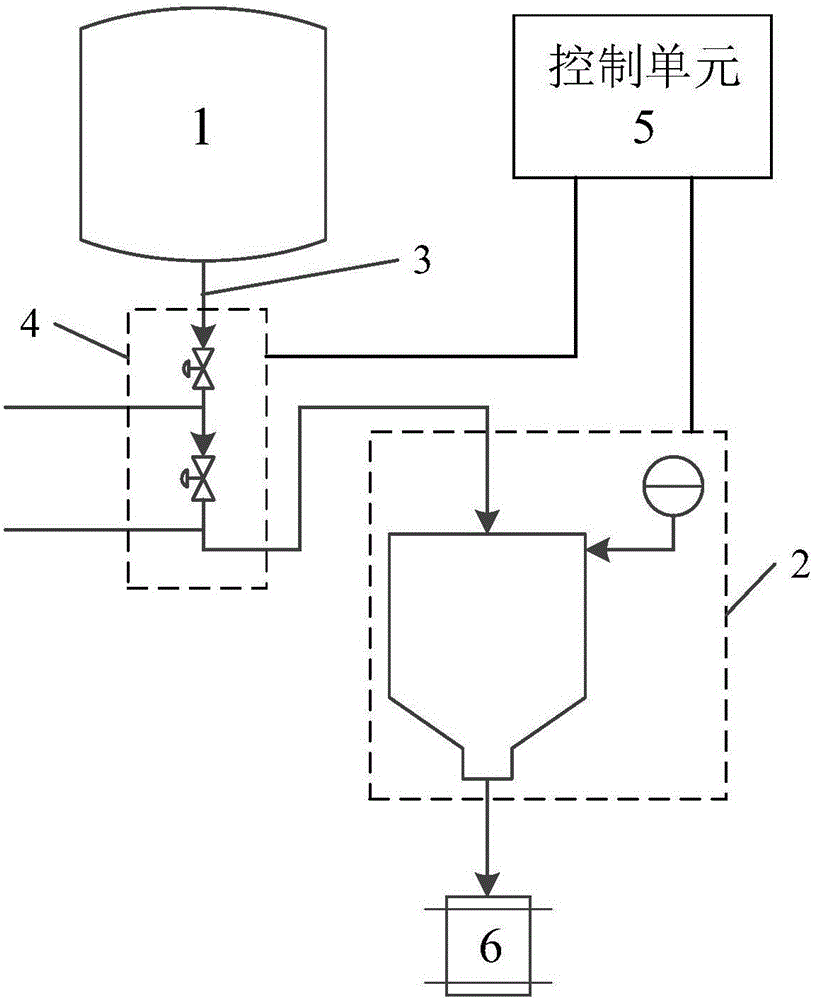

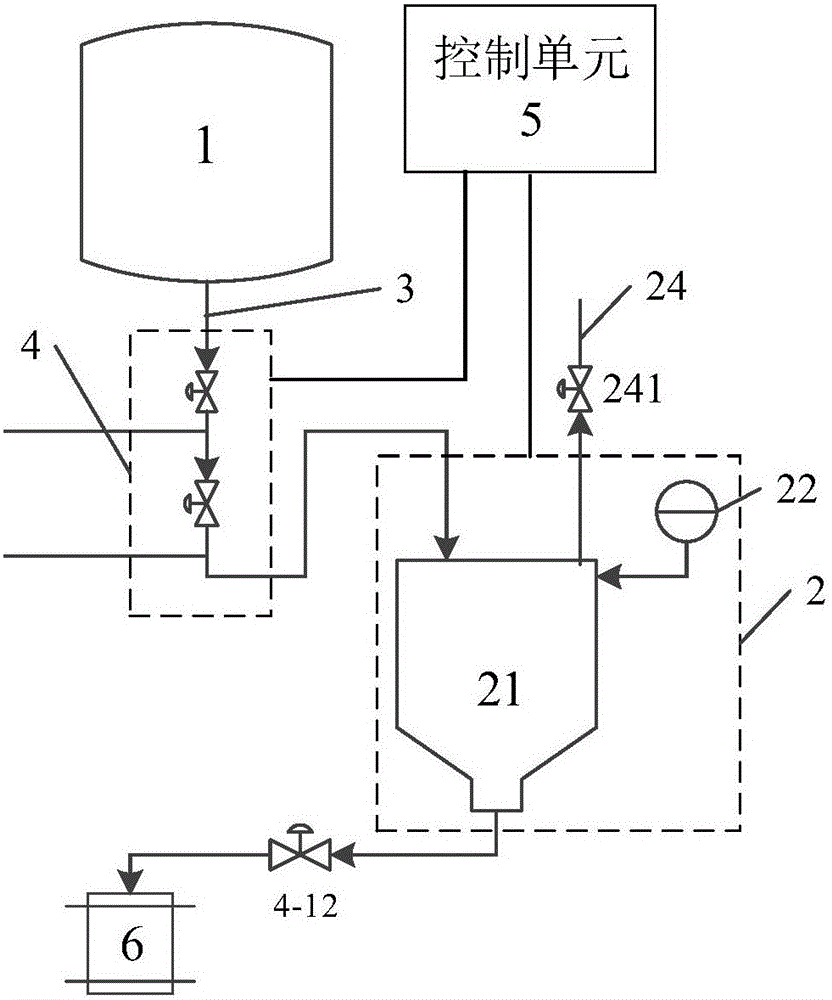

[0092] Please refer to figure 2 , the embodiment of the present invention provides a nuclear power plant waste solidification treatment system, comprising: a waste collection unit 1, a waste volume metering unit 2, a waste delivery pipeline 3 connecting the waste collection unit 1 and the waste volume metering unit 2, arranged at the waste delivery A valve assembly 4 on the pipeline 3, a control unit 5 connected to the waste volume metering unit 2 and the valve assembly 4, and a waste solidification unit 6 connected to the waste volume metering unit 2;

[0093] Waste collection unit 1, used to collect and temporarily store nuclear power plant waste;

[0094] The waste volume measuring unit 2 is used to obtain nuclear power plant waste from the waste collection unit 1 through the waste conveying pipeline 3, and measure the volume of the obtained nuclear power plant waste to obtain the waste volume;

[0095] The control unit 5 is used to obtain the waste volume from the waste ...

Embodiment 2

[0188] Based on the same inventive concept, please refer to Figure 9 , the embodiment of the present invention also provides a nuclear power plant waste solidification treatment method, which is applied to the nuclear power plant waste solidification treatment system as described in the first embodiment above. The treatment method includes the steps of:

[0189] S1. Collect and temporarily store nuclear power plant waste through the waste collection unit 1;

[0190] S2. Obtain nuclear power plant waste from the waste collection unit 1 through the waste volume measurement unit 2, and measure the volume of the acquired nuclear power plant waste to obtain the waste volume;

[0191] S3. The waste volume is obtained from the waste volume metering unit 2 by the control unit 5, and the valve switch state of the valve assembly 4 is controlled and adjusted based on the waste volume, so that the valve assembly 4 controls when the valve switch state changes. The amount of waste from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com