High-intensity gas discharge lamp

A technology of high-pressure gas and discharge lamps, which is applied to the components of gas discharge lamps, etc., and can solve problems such as inability to adapt to different needs of lighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

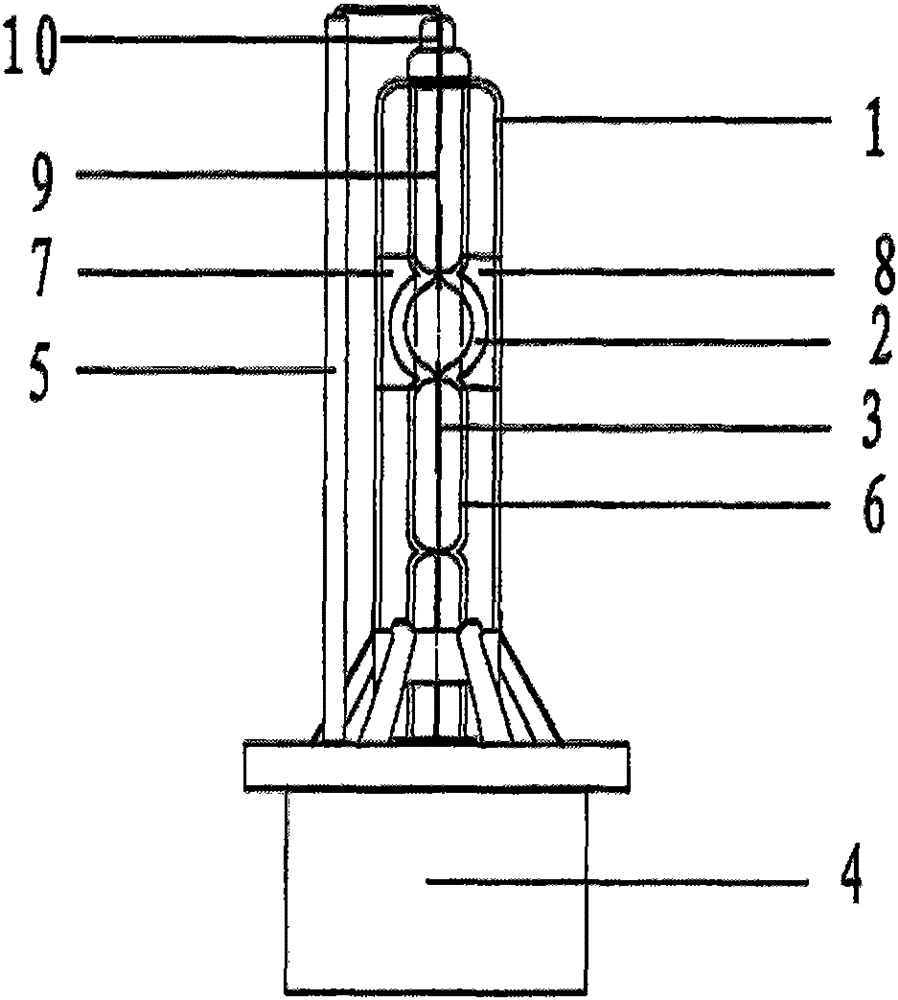

[0023] The invention provides a high-pressure gas discharge lamp, see attached figure 1 , including a glass cover 1, a discharge vessel 2, an electrode 2, a lead wire 5 and a lamp holder 4, the bottom of the glass cover 1 is fixedly connected to the center of the top of the lamp holder 4, the two ends of the glass cover 1 are sealed, one end of the lead wire 5 is drawn out from the lamp holder 4, and the other end extends Above the top of the glass cover 1, the discharge vessel 2 is set in the closed space inside the glass cover 1, and the two ends of the discharge vessel 2 are respectively provided with hoops 6, and the two ends of the discharge vessel 2 are provided with electrodes 3, and part of the electrodes 3 extends into the discharge vessel. In the capacitor 2, the remaining part is in the collar 6, and the inner wall of the glass cover 1 is provided with a coating at a position corresponding to the discharge vessel.

[0024] In the working state, the coating film is s...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, except that in this embodiment, in the working state, the coating film of the high-pressure gas discharge lamp is distributed on the top 1 / 2 area of the inner wall of the glass outer cover.

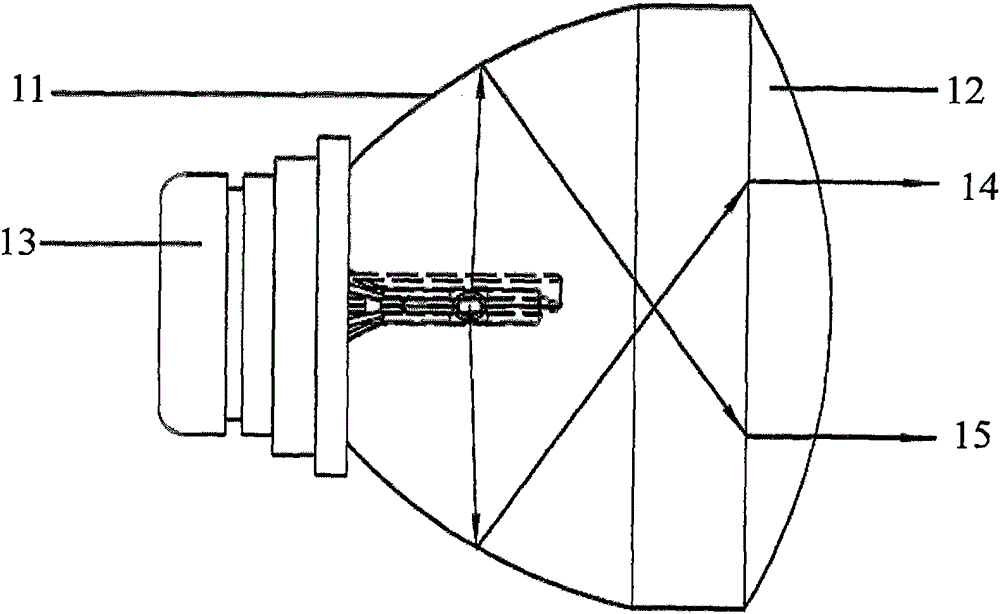

[0033] The light emitted by the high-pressure gas discharge lamp in this embodiment is reflected by the reflective cup and refracted by the convex lens, so that the upper part of the car headlight emits light with a color temperature of 4500k-6500k and high brightness, and the lower part emits light of 3000k-3500k The light with a longer wavelength; the light with a color temperature of 4500k-6500k can make road lighting whiter, brighter and safer, while the light with a color temperature of 3000k-3500k has a longer irradiation distance and stronger penetration of rain, snow and fog; thus Realizing a high-pressure gas discharge lamp can change its illumination effect according to different road conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com