Oxygen separator and method for generating oxygen

An oxygen separator, oxygen sensor technology, applied in separation methods, chemical instruments and methods, oxygen/ozone/oxide/hydroxide, etc., to improve reliability, prevent the negative effects of measurement quality degradation, easily and directly The effect of analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

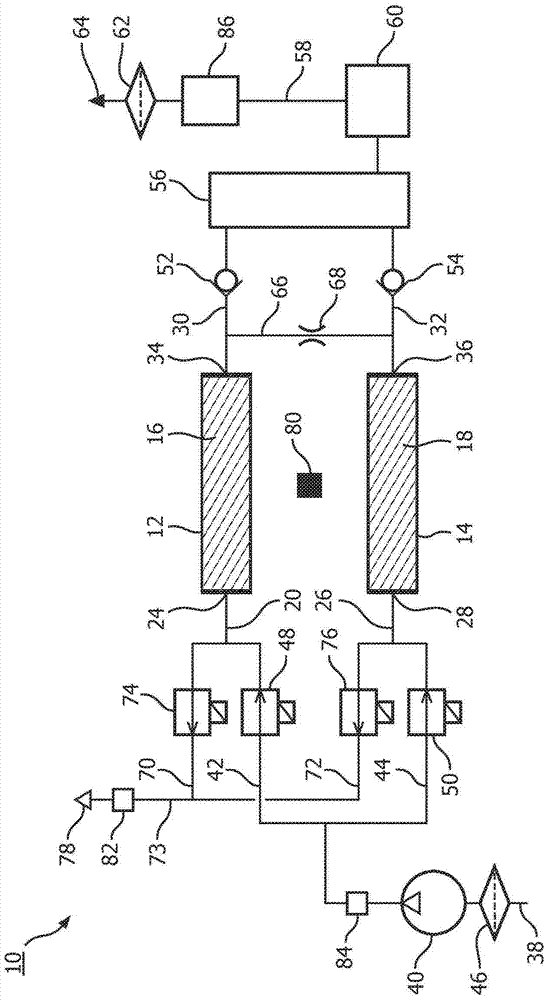

[0057] exist figure 1 In , an exemplary embodiment of an oxygen separator 10 for generating oxygen is schematically shown. The oxygen separator 10 may be used to generate oxygen for therapeutic applications, for example in the field of COPD treatment. The oxygen separator 10 may be designed as a fixed arrangement, eg for use in a hospital, or it may be a portable device, eg for use in home care applications. However, the oxygen separator 10 may also be used in any application where pure or substantially pure oxygen must be provided, such as in aircraft or for welding purposes. Such an oxygen concentrator or oxygen separator 10 may accordingly be an oxygen concentrator according to, for example, the type known as SimplyGo and commercially available from Philips Respironics.

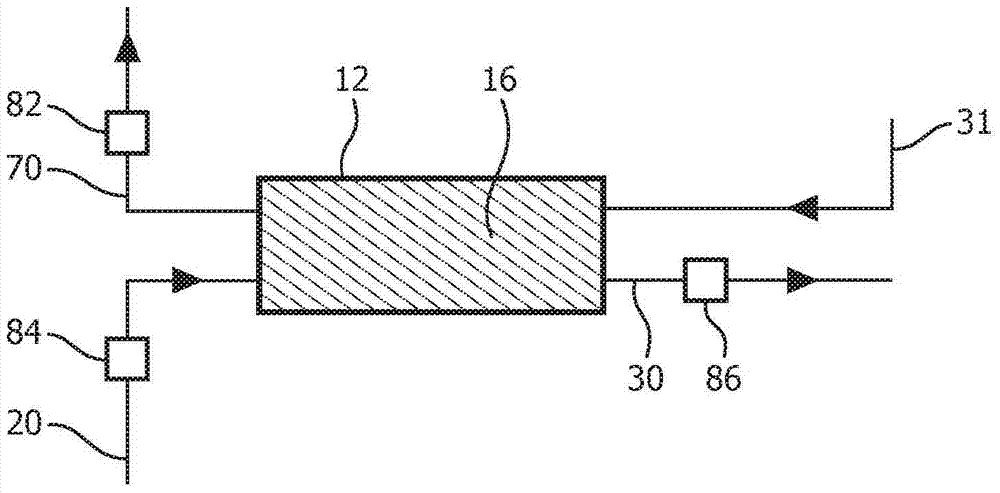

[0058] according to figure 1 The oxygen separator 10 includes at least one oxygen separation device 12 capable of separating oxygen from an oxygen-containing gas. However, it is preferred that the oxyg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com