A circulating energy-saving and water-saving fast steamer

A circulation type, steamer technology, applied in the field of steamer, can solve the problems of large environmental impact, heat loss, poor steam cycle effect, etc., to achieve the effect of eliminating steam escape, accelerating heating speed, and reducing heat energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

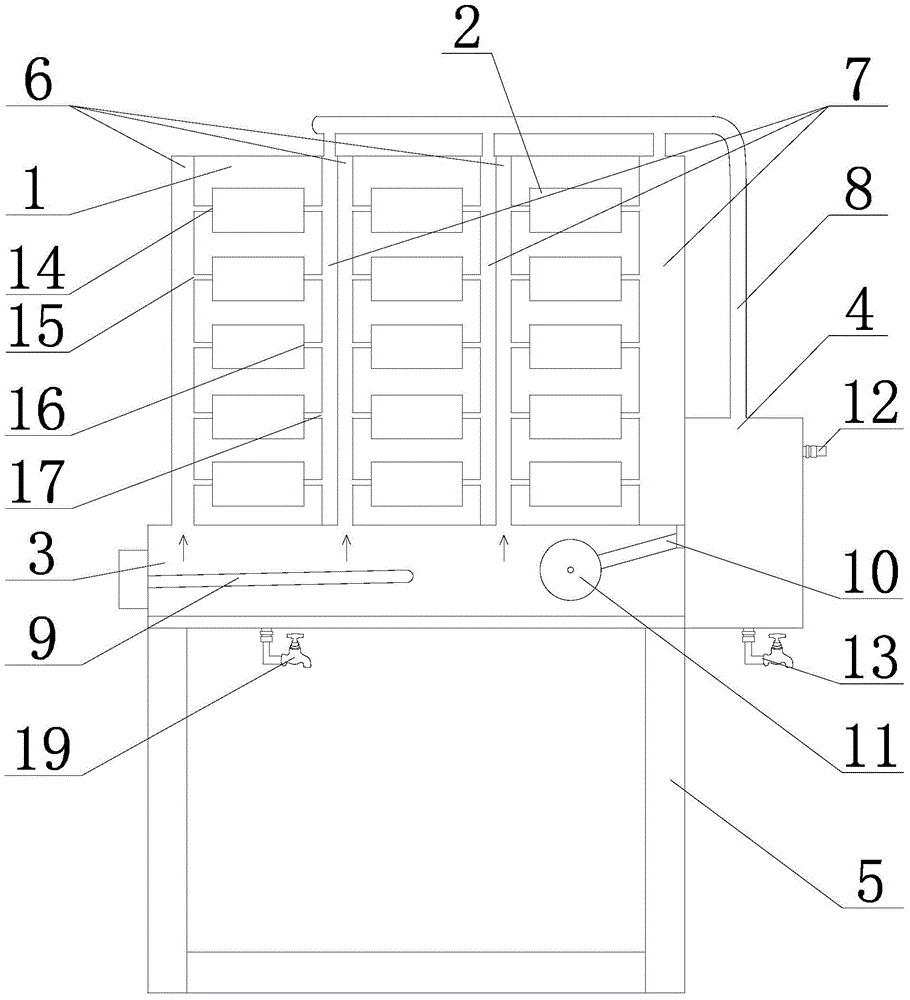

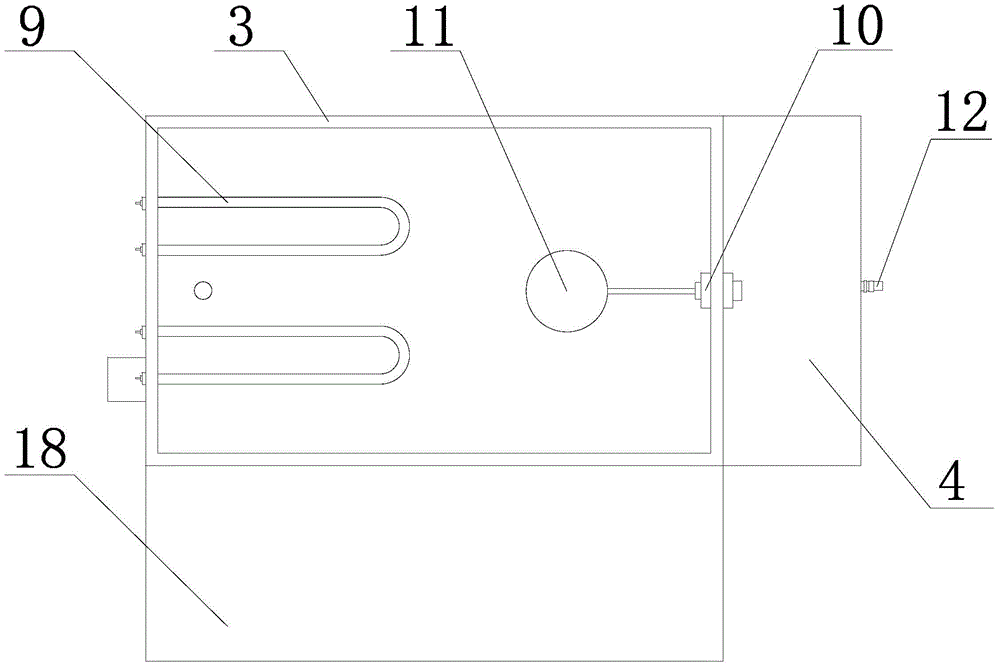

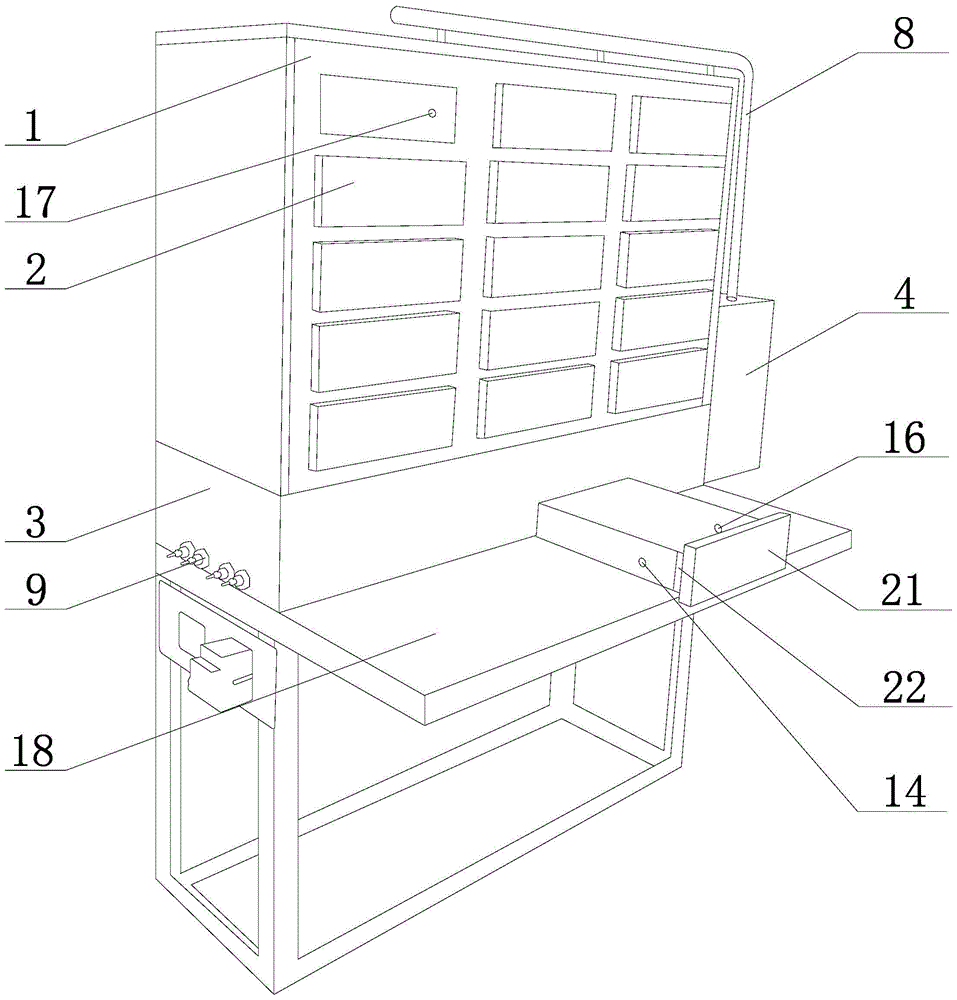

[0028] Figures 1 to 3 Among them, a circulating energy-saving and water-saving fast steamer includes a steaming rack 5, a steaming box 1, a water tank 3 and a heating device, the heating device provides a heat source for the water in the water tank, the heating device is an electric heating device 9, and the electric heating device 9 The electric heating tube is located in the water tank 3, and provides heating for the water in the water tank through the electric heating tube. The electric heating device 9 is fixed on the steamer 1 with screws through the flange and the protective shell, and the steamer 1 is provided with a switch and a protection device. The electric heating device 9 is provided with a connection terminal, and is connected with a temperature controller, and the output temperature and closing of the electric heating tube are set as required. The water tank 3 is located above and below the steaming rack 5, and one side of the water tank 3 is provided with a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com