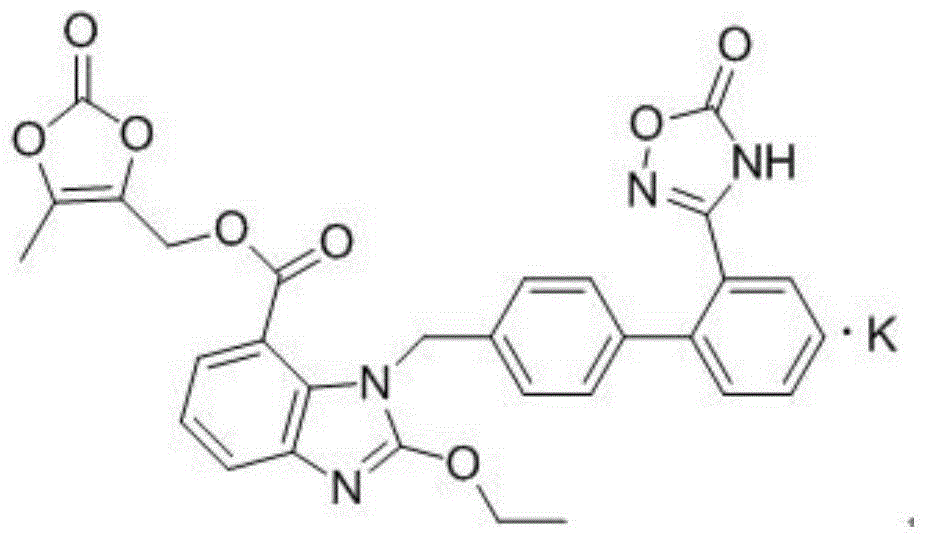

Azilsartan medoxomil potassium combination and preparation method thereof

A technology of azilsartan medoxomil potassium and azilsartan medoxomil, which is applied in the field of pharmaceuticals and can solve problems such as preparation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0043] In order to enable those skilled in the art to better understand the technical solutions of the present invention, some non-limiting examples are further disclosed below to further describe the present invention in detail.

[0044] The mannitol, microcrystalline cellulose, croscarmellose sodium, hydroxypropyl cellulose and magnesium stearate used in the present invention meet the standards of pharmaceutical excipients in the Chinese Pharmacopoeia 2010 edition.

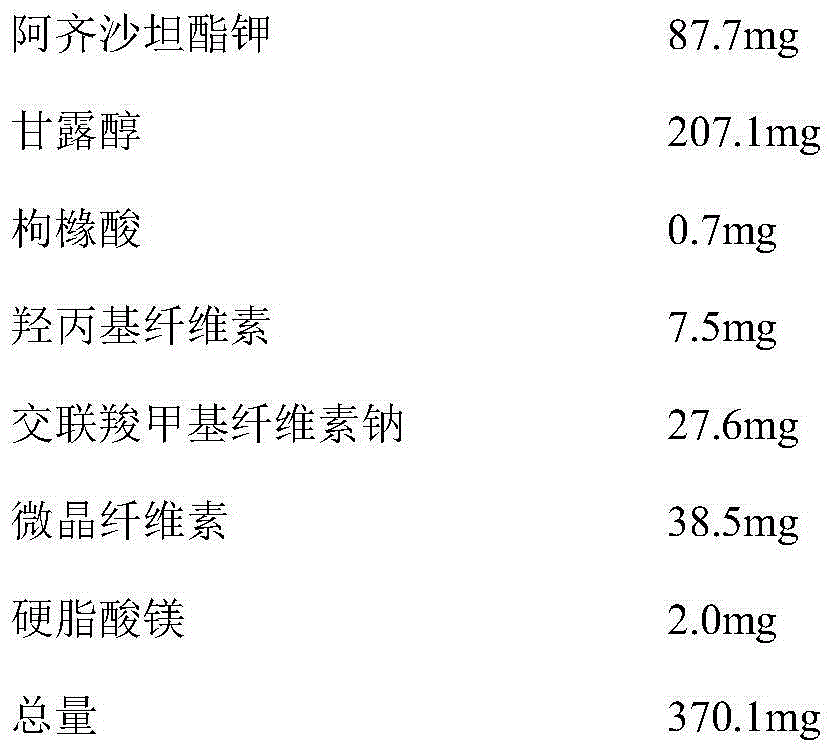

Embodiment 1

[0046]Weigh 335g of mannitol, 44.8g of croscarmellose sodium and 142.2g of azilsartan medoxomil potassium, mix them evenly and place them on the Chongqing Zilong fluidized bed to preheat to 40°C, and then start the process at 35±3 Spray a mixed solution made of 12.2g hydroxypropyl cellulose, 1.2g citric acid and appropriate amount of water under the condition of ℃, the pH value is about 2.53, and dry on a fluidized bed, and then carry out granulation on a QUADRO granulator, Pass 055R sieve. 3.3 g of magnesium stearate and 62.4 g of microcrystalline cellulose were added and mixed together uniformly to obtain a mixture. Finally the resulting mixture was pressed into a composition with a hardness of 90N.

[0047] Composition of the preparation (370.1 mg per tablet)

[0048]

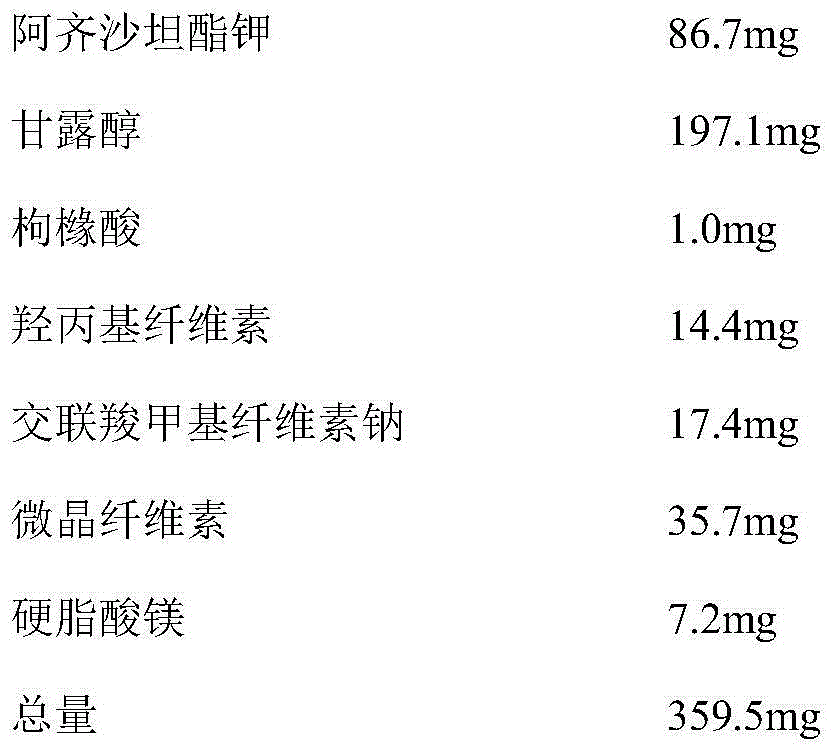

Embodiment 2

[0050] Weigh 329.0g of mannitol, 29.0g of croscarmellose sodium and 144.7g of azilsartan medoxomil potassium, mix them evenly and place them on the Chongqing Zilong fluidized bed to preheat to 40°C, and then start at 35± Spray a mixed solution made of 24.1g hydroxypropyl cellulose, 1.7g citric acid and appropriate amount of water at 3°C, the pH value is about 2.46, dry it on a fluidized bed, and then granulate it on a QUADRO granulator , through 055R sieve. 12.1 g of magnesium stearate and 59.6 g of microcrystalline cellulose were added and mixed together uniformly to obtain a mixture. Finally the resulting mixture was pressed into a tablet with a hardness of 90N.

[0051] Composition of the composition (359.5 mg per tablet)

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com