Hose lines for fresh and/or used dialysate

A dialysate and hose technology, used in dialysis systems, drug devices, other medical devices, etc., can solve the problems of high temperature loss of hot water, lack of weight errors, and inability to ensure, to reduce temperature loss and quality changes. Reduce and realize the effect of quality change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

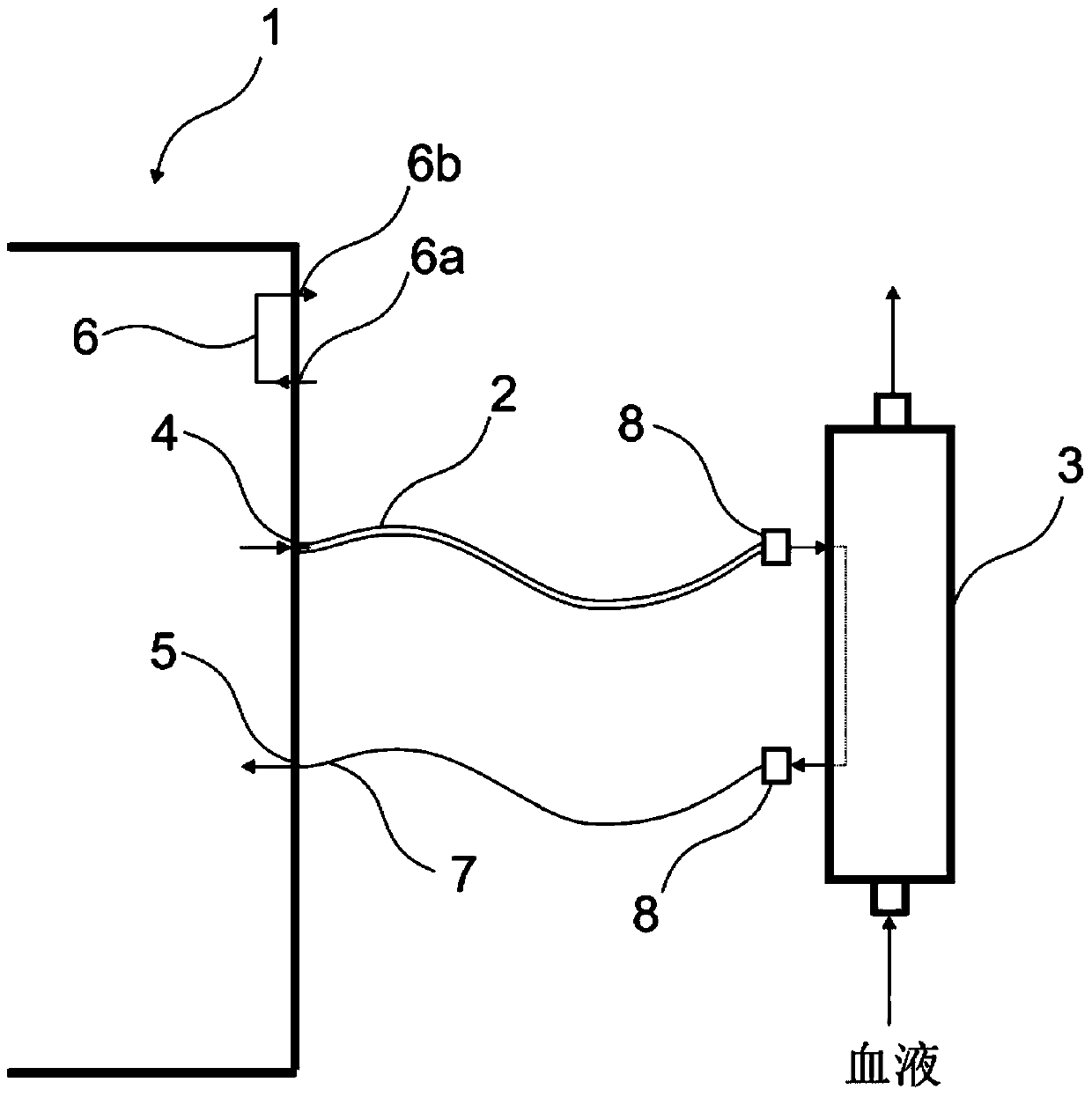

[0064] figure 1 Shown is a simplified view of a dialysis machine 1 via a first hose line (hose supply line) 2 for fresh dialysate and a second hose line for used dialysate according to one embodiment. Two hose lines (hose outlet lines) 7 are connected to the dialyzer 3 .

[0065] Dialysis machine 1 in figure 1 marked on the left. Dialysis devices or dialysis machines are known per se, so details of the dialysis machine 1 , such as internal components which are not directly related to the dialysate hose lines 2 , 7 , are not shown for reasons of clarity.

[0066] In the described example already as in figure 1 As shown in the dialysis machine 1, there is in particular a dialysate outlet 4, which represents the flow direction from fresh dialysate to a dialyzer 3 arranged outside the dialyser 1; a dialysate inlet 5, which provides Outflow of used dialysate from dialyzer 3; cleaning bridge 6, with an inlet 6a and an outlet 6b each for cleaning fluid, through which first hose l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com