Double-shaft differential type crusher

A differential type, crusher technology, applied in grain processing and other directions, can solve the problems of sliding surface wear, surface corrosion of disc cutters, easy corrosion of chrome-molybdenum steel, etc. The effect of frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the twin-shaft differential crusher according to the present invention will be described in detail with reference to the drawings.

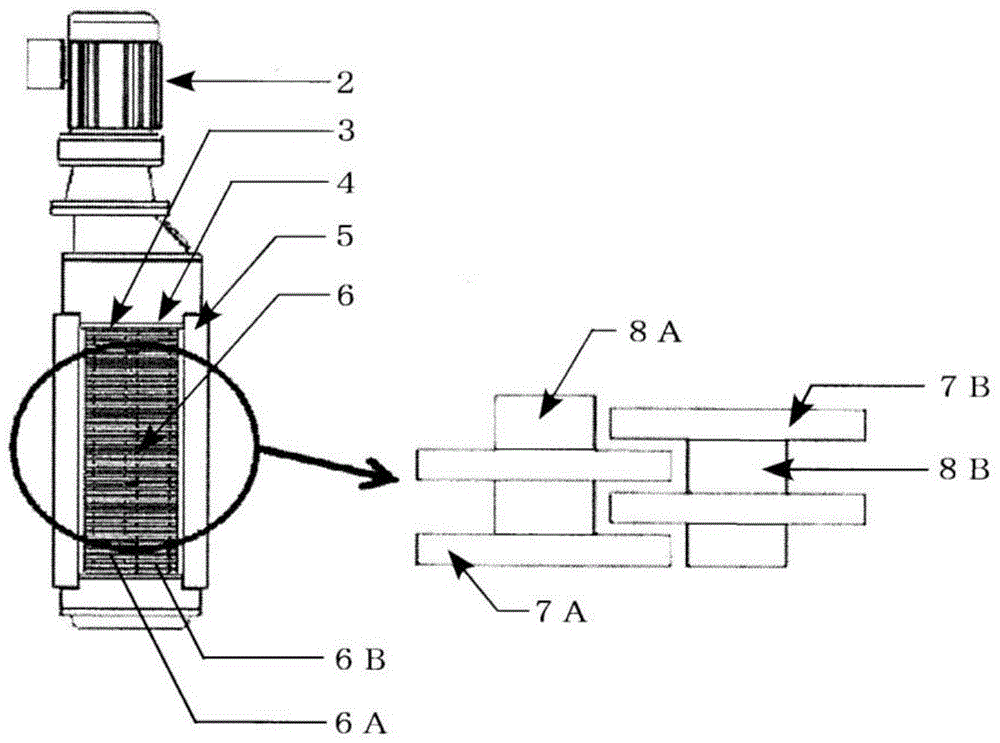

[0026] figure 1 It is a schematic explanatory diagram showing the structure of a twin-shaft differential crusher 1 according to an embodiment of the present invention.

[0027] [Twin Shaft Differential Crusher]

[0028] The double-shaft differential crusher 1 of the embodiment of the present invention includes: a drive motor 2; a drive shaft 3 driven by the drive motor 2; a driven shaft 4 transmitted with the rotational power of the drive shaft 3 driven; shell 5; and cutter portion 6.

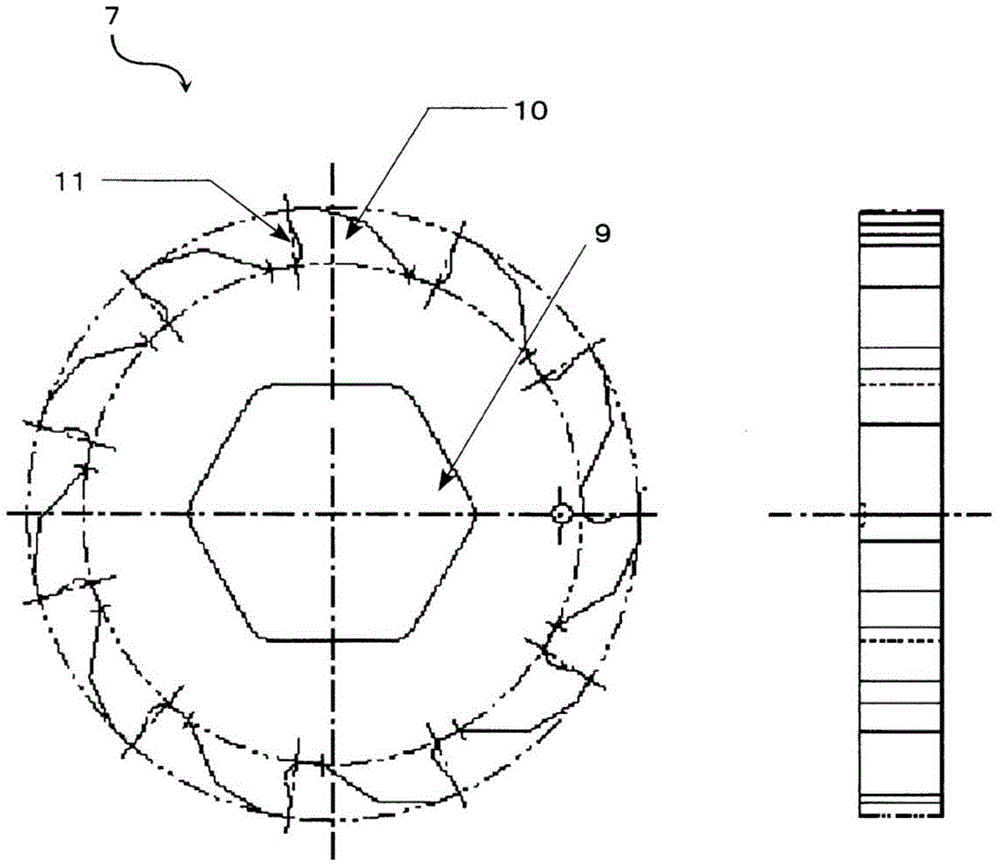

[0029] In addition, the cutter portion 6 is composed of the following units: a cutter unit 6A composed of a drive shaft 3 and a plurality of ceramic cutters 7A and bushings 8A arranged around the drive shaft 3; The unit 6B is composed of a driven shaft 4 and a plurality of ceramic cutters 7B and bushings 8B arranged around the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com