Sawing machine and sawing machine control method

A control method and technology of a machine control device, which are applied in shearing machine control devices, automatic control devices, manufacturing tools, etc., can solve the problems that sensors cannot be successfully realized, and achieve the effect of shortening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

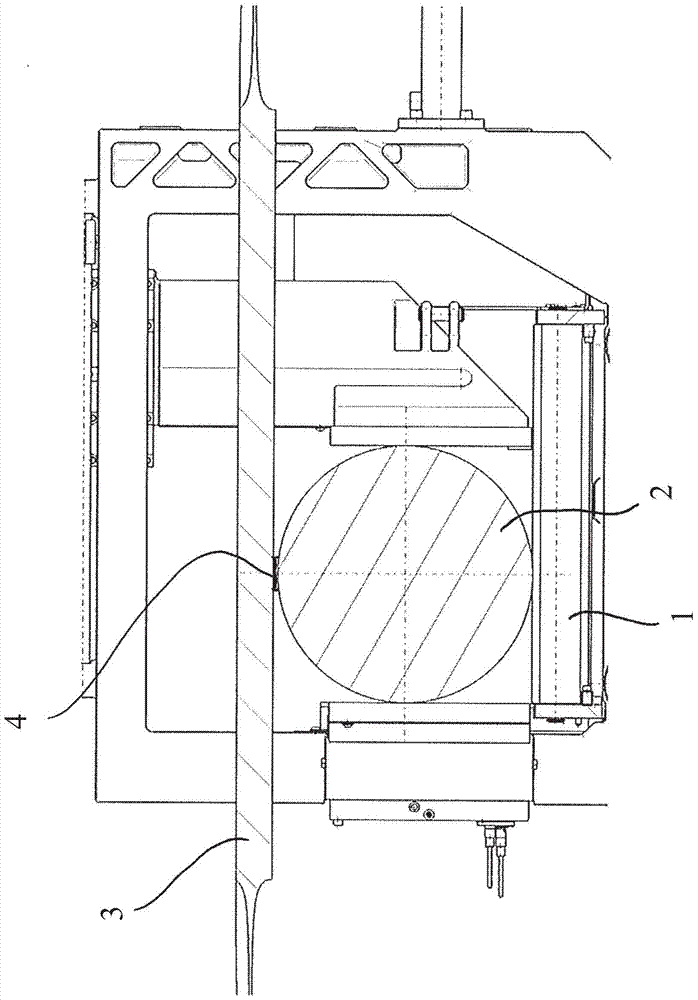

[0034] figure 1 A saw table 1 of a band saw machine is schematically shown, on which a workpiece 2 (here a cylindrical strip) is placed. Above the workpiece, the saw band 3 as a saw blade circulates around two deflection rollers (not shown) in the upper part of an elevating saw machine. The saw band moves from right to left within the drawing in the selected view.

[0035] Such as figure 1 The moment shown is the start of the actual cutting process: the saw band 3 moves downwards during the feed movement in the cutting plane which coincides with the drawing plane in the selected view and moreover comes into contact with the workpiece 2 . In the joining section 4 , the saw band 3 cuts into the material of the workpiece 2 and cuts through the workpiece by the cutting action of the saw teeth arranged on the lower end of the saw band 3 .

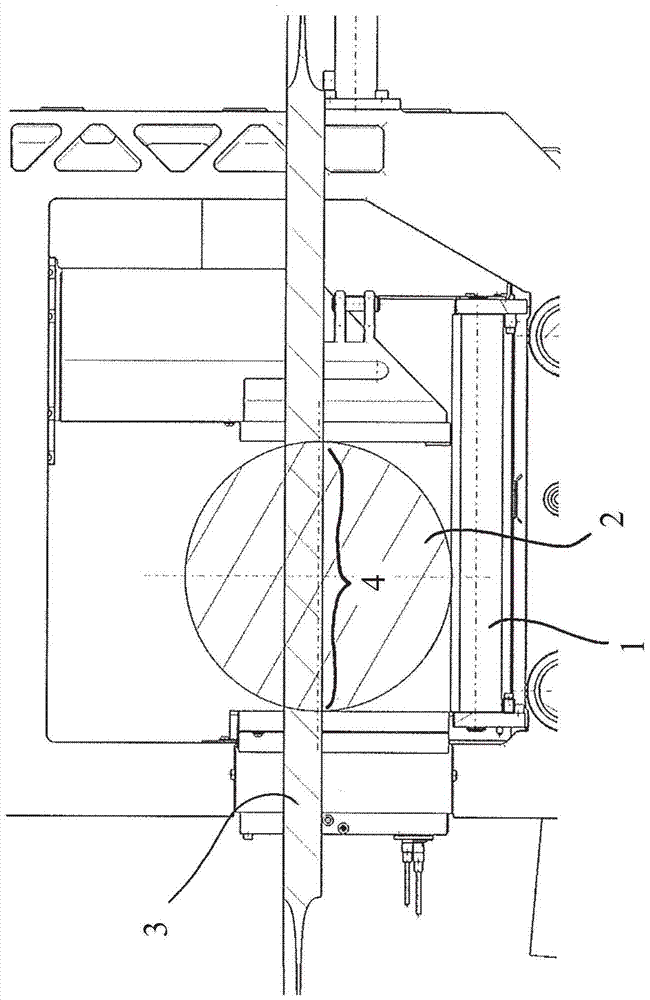

[0036] figure 2 A later moment in the cutting process is shown. Here, the saw band 3 is located approximately in the center of the cross-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com