Magnetic control device for resistance spot welding with adjustable position

A technology of resistance spot welding and magnetron device, applied in resistance welding equipment, welding equipment, transportation and packaging, etc., can solve the problems of difficult adjustment of working distance of magnetron device, reduced automobile production rhythm, fragile permanent magnet, etc. To achieve the effect of easy replacement, convenient operation and enhanced stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

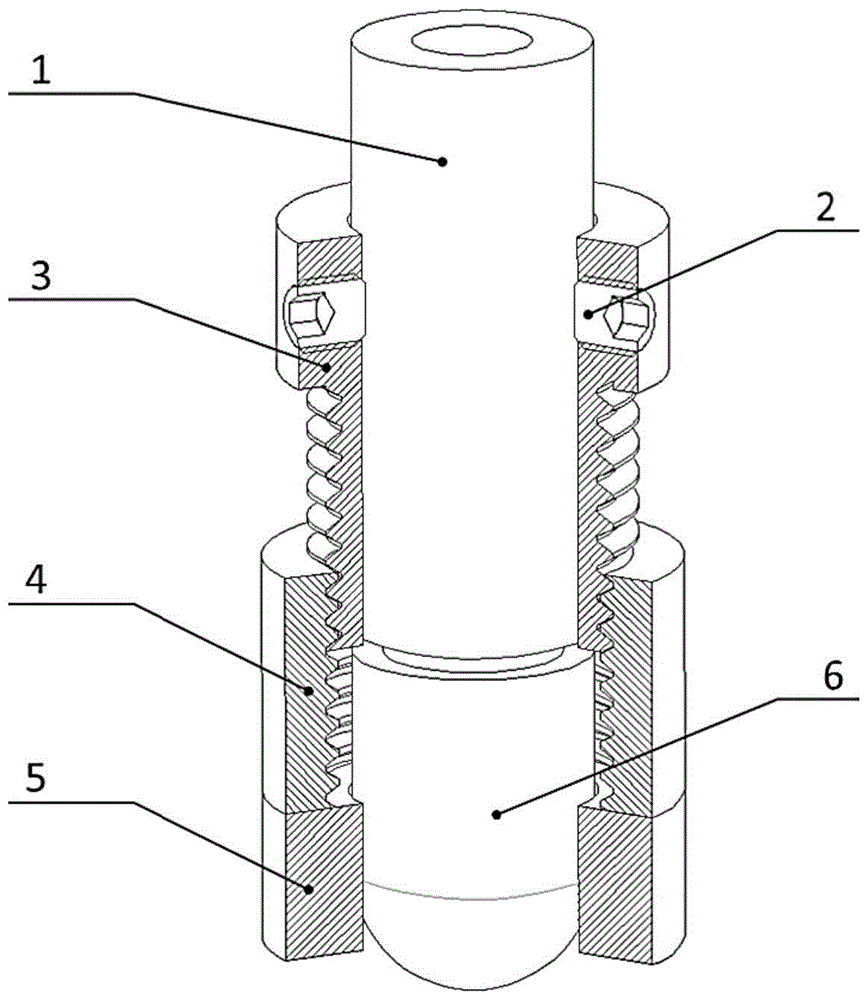

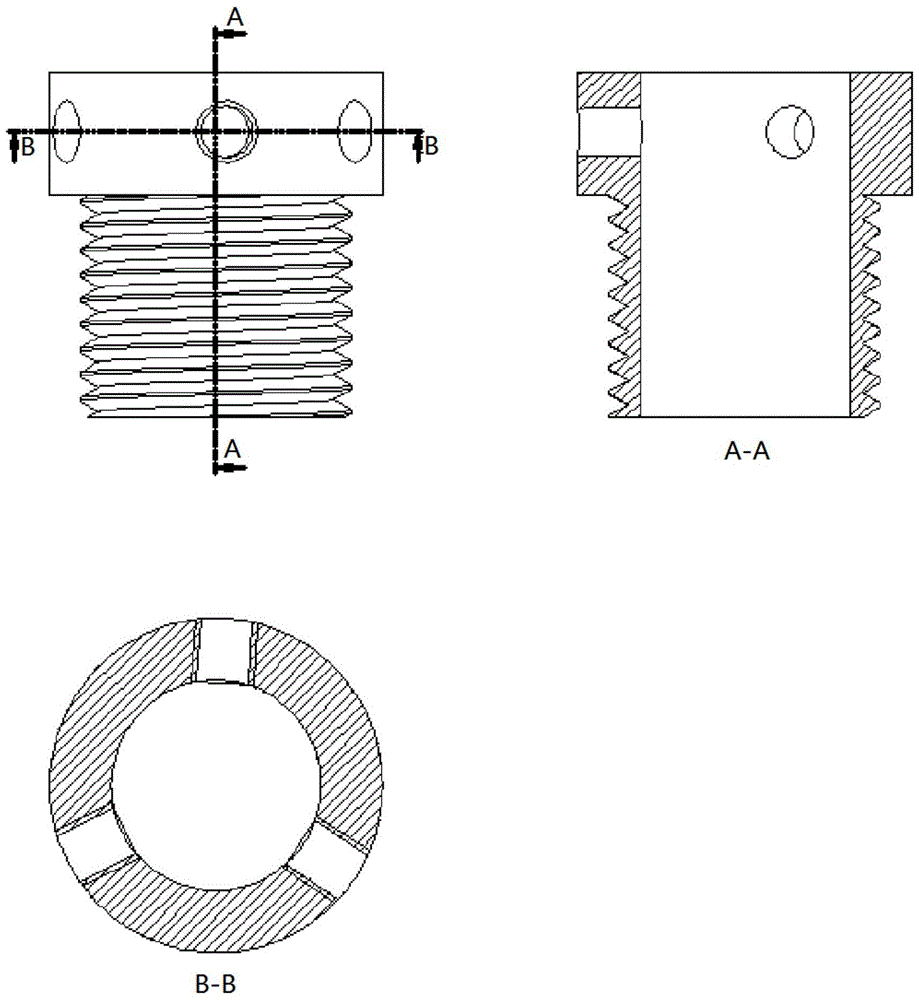

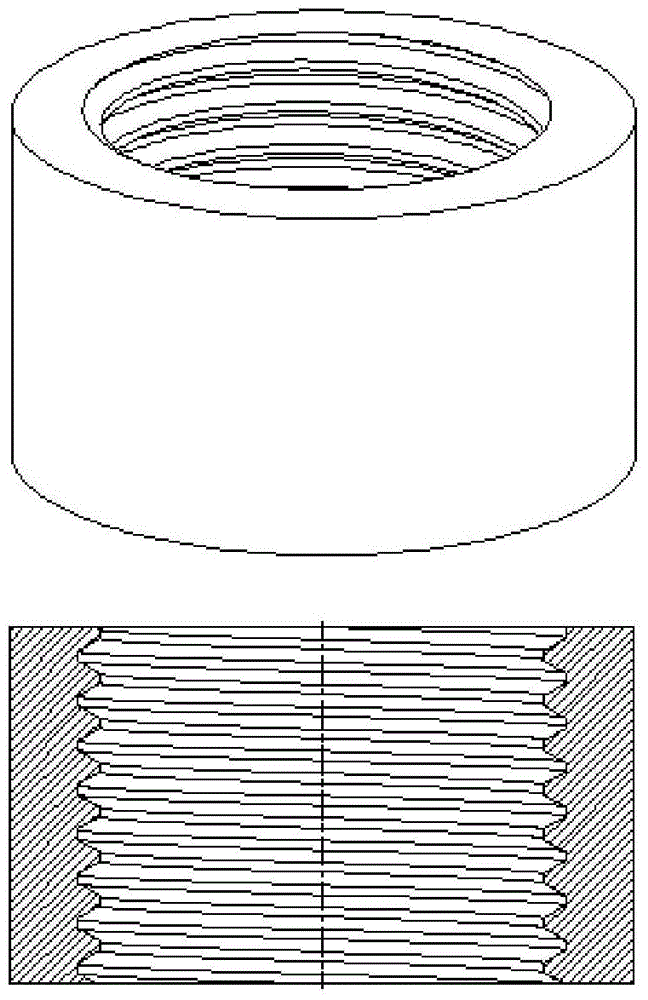

[0038] like Figure 5 As shown, this embodiment includes: electrode rod 1, positioning screw 2, bushing 3, positioning guide sleeve 4, annular permanent magnet 5, electrode cap 6, plate 7 and electrode dresser 8, wherein: bushing 3 and electrode The rod 1 is fixedly connected by a positioning screw, the positioning guide sleeve 4 is movably socketed with the bushing 3, the annular permanent magnet 5 is fixedly connected with the positioning guide sleeve 4, and the electrode cap 6 is connected with the electrode rod 1.

[0039] The magnetization direction of the annular permanent magnet 5 is parallel to its axis of symmetry, and its magnetic field distribution is axisymmetric.

[0040] The number of the ring-shaped permanent magnets 5 is 1 pair, and the polarities are mutually exclusive, so as to realize double-sided stirring.

[0041] The annular permanent magnet 5 has an inner diameter 0.5mm larger than the outer diameter of the electrode rod, a wall thickness of 5mm, and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com