Portal vertical machining center

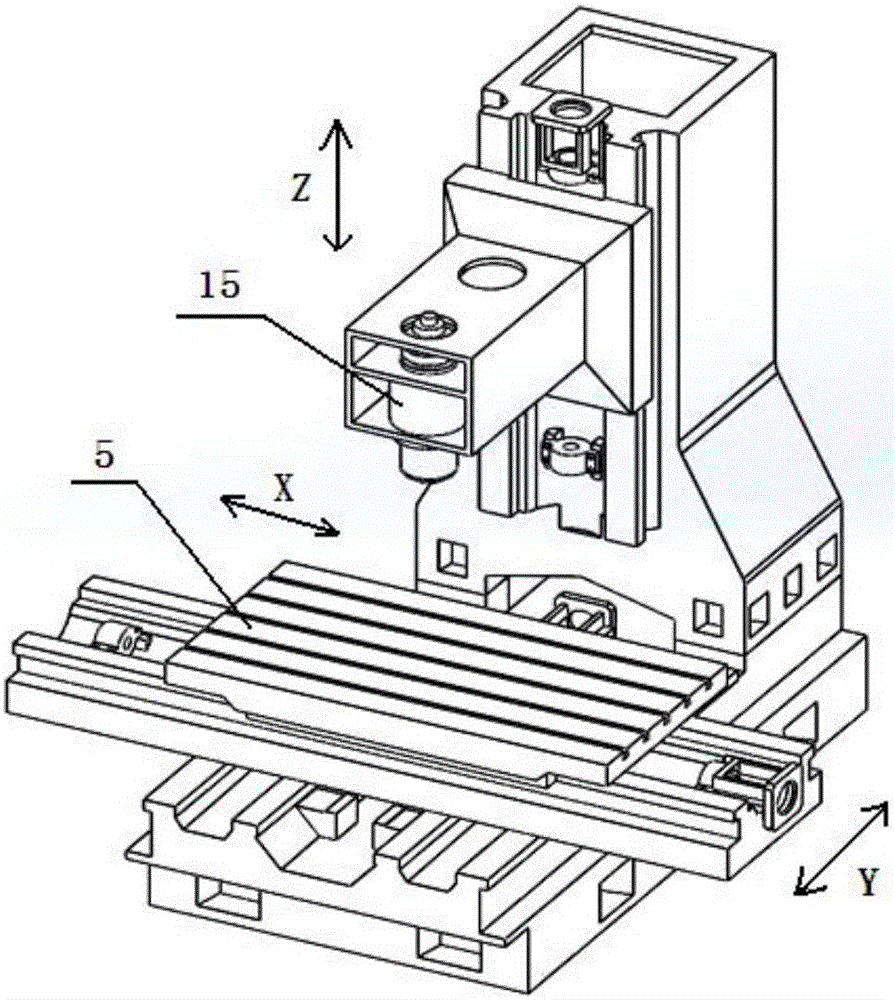

A vertical machining center and door-type technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of excessive cutting vibration, affecting the processing precision, product surface finish, and affecting the rigidity of the processing spindle 15, etc. , to achieve the effect of avoiding vibration, good rigidity and avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

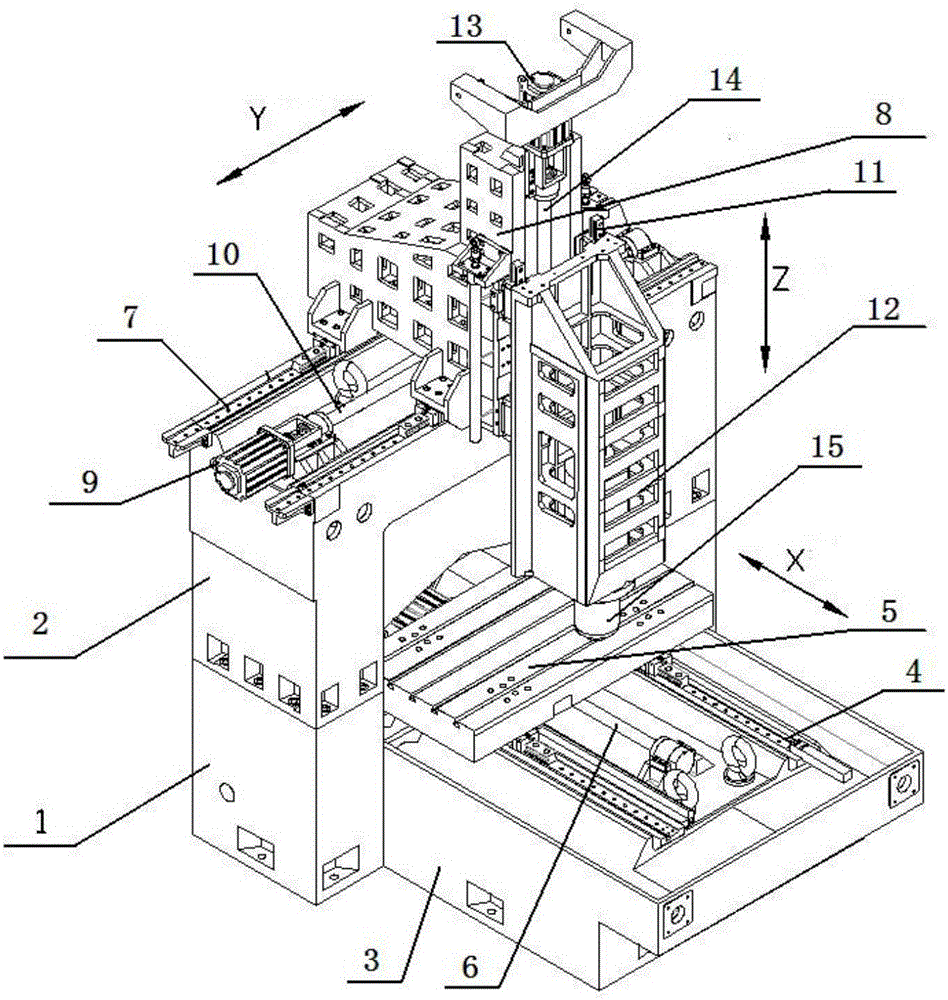

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0016] The invention provides a door-type vertical machining center, such as figure 2 With the structure shown, the machining center has good rigidity, good stability, high machining precision, and has a good market promotion prospect.

[0017] Such as figure 2 The portal-type vertical machining center shown includes a bed 1, a portal frame 2 and a base 3 are arranged on the bed 1, the portal frame 2 spans above the base 3, and a portal frame 2 is arranged on the base 3 The guide rail one 4 in the horizontal direction perpendicular to the plane where the plane is located is installed with a workbench 5 that can move along the guide rail one 4 along the X axis; the workbench 5 passes through the X axis servo motor (not shown) and the lead screw one 6 drives it to move back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com