A rotating cracking pipe structure

A technology for rotating structures and pipes, applied in sugarcane machining, manufacturing tools, mechanical equipment, etc., can solve the problems of complex mechanical devices, poor toughness, and low output of bamboo silk, and achieve the effects of stable rotation, fast cracking, and resource saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

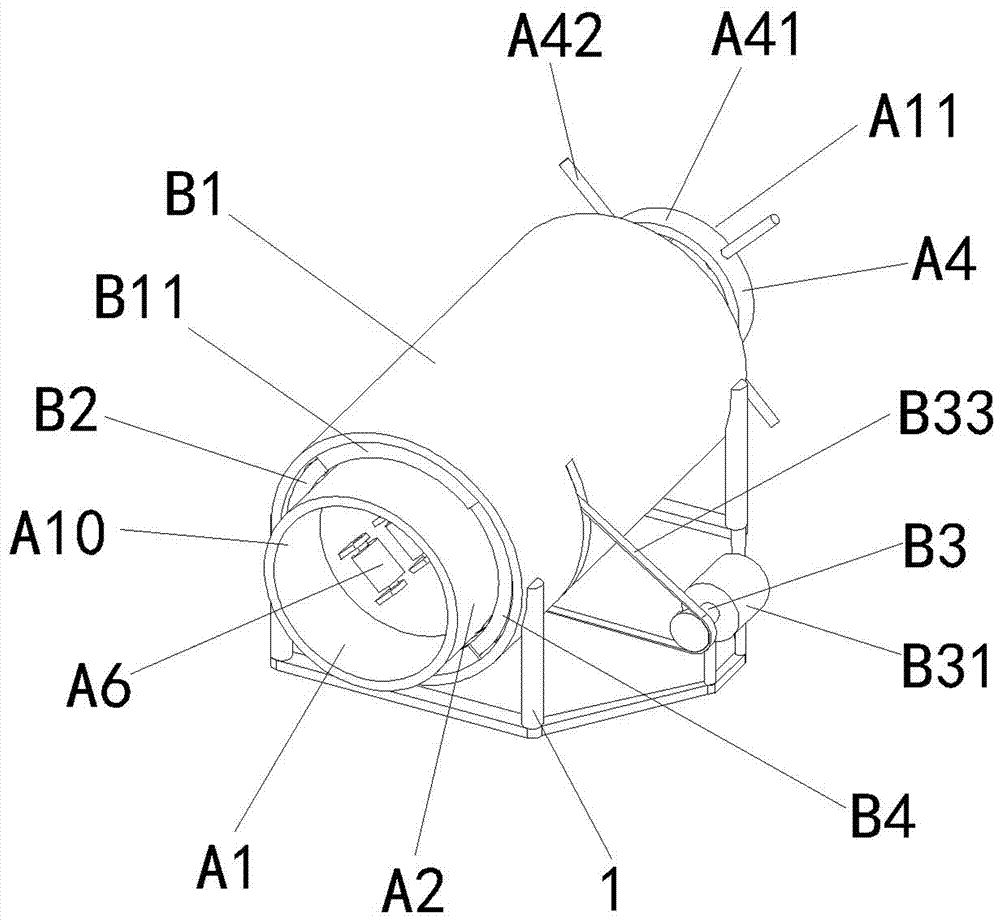

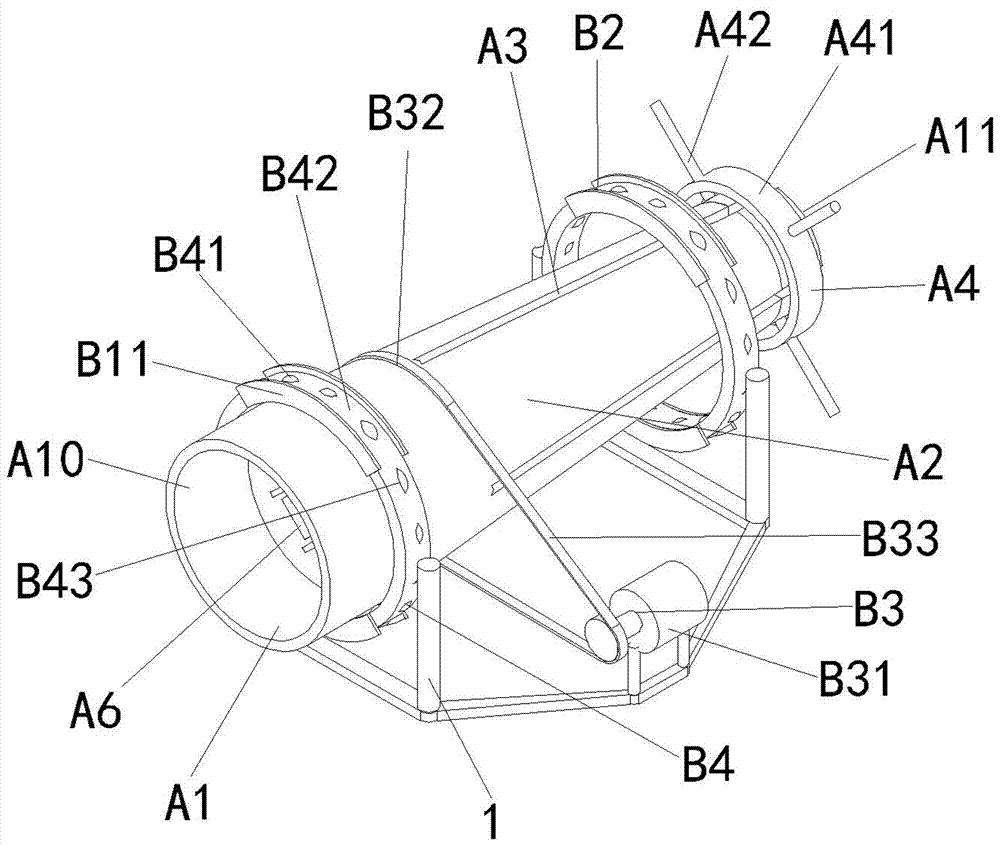

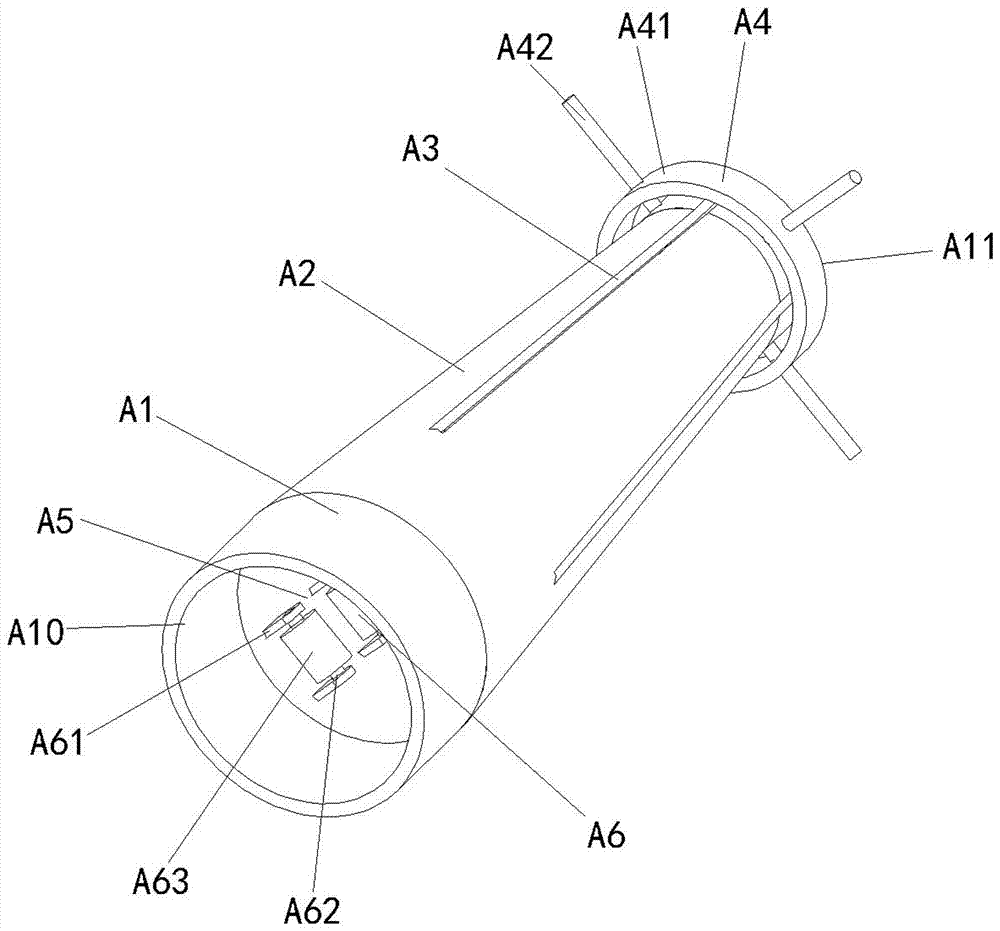

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 or Image 6 The shown rotating and cracking pipe structure includes openings at both ends for accommodating the bamboo pole pipe container A1. A bushing body B1 is arranged outside the pipe container A1. The bushing body B1 is fixedly connected with a bracket body 1. One end of the pipe container A1 is the first The end opening A10, the first end opening A10 is a circle with a diameter of 20cm, and a container wall A2 is arranged on its circumference, and the diameter of the cross-section at each place of the container wall A2 is equal to the first end opening A10. The other end is the second end opening A11, six notches are arranged on the circumference of the second end opening A11, and the notches extend along the axial direction of the pipeline container A1 to form an empty groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com