Cooling water circulating and recycling system for plastic machine equipment

A technology of cooling water circulation and equipment, applied in the direction of filtration circuit, filtration separation, chemical instruments and methods, etc., can solve the problem of waste of water resources and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

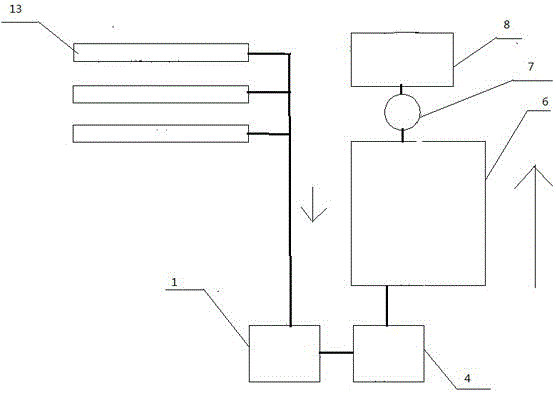

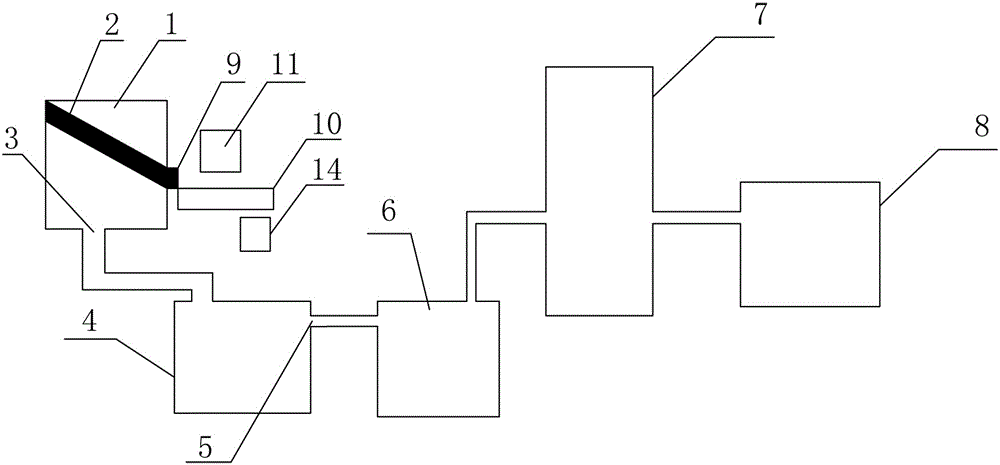

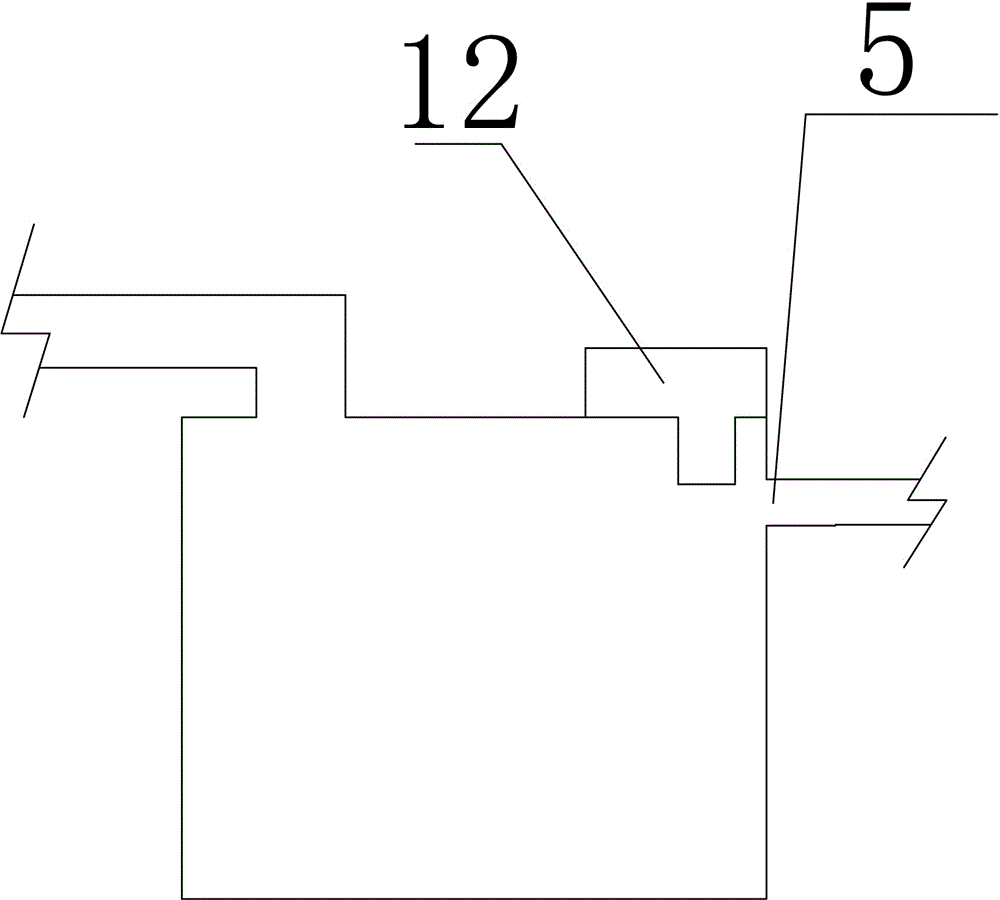

[0015] Such as figure 1 Among them, a cooling water recycling system for plastic machinery equipment includes a filter pool 1, a filter screen 2 is provided on the upper part of the filter pool 1, and a filter port 3 is provided at the bottom of the filter pool (preferred filter pool 1 is located underground), and the filter screen 2 is placed on an inclined plane, and the recovery port 9 on the wall of the filter tank 1 communicates with the lower part of the screen surface of the filter screen 2. Preferably, the recovery port 9 communicates with the vibrating screening machine 10, and a hot air blower 11 is arranged above the vibrating screening machine 10. The air outlet of the fan 11 is vertically aligned with the vibrating screening machine 10, and a winnowing machine 11 is arranged below the outlet of the vibrating screening machine 10. The winnowing machine 14 can winnow the material at the outlet of the vibrating screening machine 10, and the sedimentation tank 4 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com