Printing plate structure and manufacturing method thereof

A technology of printing plates and dots, which is applied in the field of printing plate structure and its production, can solve the problems of printing quality degradation, affecting printing quality, increasing dot printing expansion value, etc., to achieve the effect of reducing deformation, improving resistance rate and exquisite printing patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

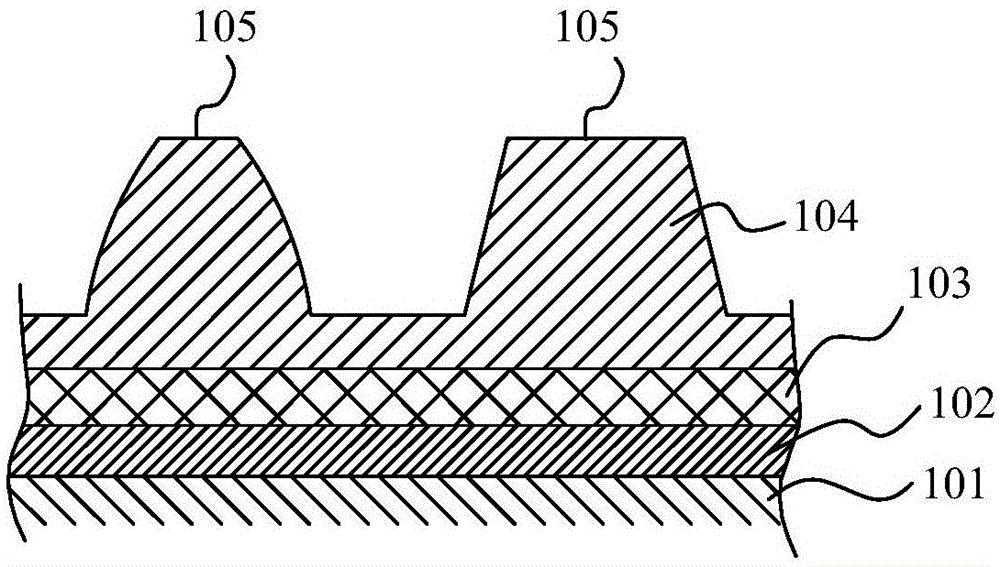

[0059] Satellite flexographic plates for film printing using a laser to directly engrave a rubber plate.

[0060] The printing plate adopts the RIP precision of 2400PPI, the number of screening lines is 150LPI, the angle is 45°, and the dot type is round dots for screening. The relief height of the raised points is 0.55mm. And according to the RIP accuracy and the number of screen lines, the number of tones between 0-100% is 256. Determine the engraving outline of 256 tones according to the 8BitTIFF engraving file of the original laser machine.

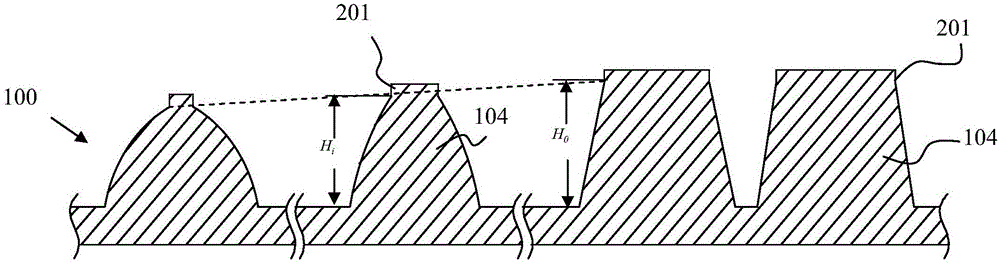

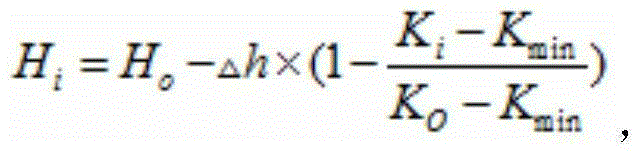

[0061] Improve the printing durability of the printing plate, prevent the printing plate from increasing the dot printing expansion value after wear, and add a column head of a cylinder with a height of 8 μm on the top of the convex point of each tone. This printing plate is used for printing plastic films. Its surface It is smooth and not easy to wear the printing plate. It is more appropriate to choose a value of 8 μm at the lower...

Embodiment 2

[0066] Steel-based letterpress for can printing using laser direct engraving of rubber plates.

[0067] The printing plate selects the RIP accuracy of 5080PPI, the number of screen lines is 200LPI, the angle is 45°, and the dot type is round dots for screening. The relief height of the raised points is 0.4mm. According to the RIP accuracy and the number of screen lines, the number of tones between 0-100% is 646. According to the 8BitTIFF engraving file of the original laser machine, the engraving outline of 646 tones is determined.

[0068] In order to improve the printing durability of the printing plate and prevent the printing plate from increasing the dot printing expansion value after wear, a 6μm cylindrical column head is added on the top of the convex point of each tone. Since the printing plate is used for aluminum cans, its surface is smooth and it is not easy to wear the printing plate, so it is more appropriate to choose a smaller value of 6 μm.

[0069] The heig...

Embodiment 3

[0073] Flexographic plates for on-set printing using a laser to directly engrave the rubber plate.

[0074] The printing plate selects the RIP accuracy of 4000PPI, the number of screen lines is 175LPI, the angle is 37.5°, and the dot type is round and square dots for screening. The relief height of the raised points is 0.60mm. According to the RIP accuracy and the number of screen lines, the number of tone between 0-100% is 524. According to the 8BitTIFF engraving file of the original laser machine, the engraving outline of 524 tones is determined.

[0075] In order to improve the printing durability of the printing plate and prevent the printing plate from increasing the dot printing expansion value after wear, a 14μm cylindrical column head is added at the top of each tone. Since the printing plate is used for printing cardboard, its surface is rough and easy to wear the printing plate, it is more appropriate to choose a value of 14 μm above the middle.

[0076] The heigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com