Special ultrasonic dirty oil sludge deoiling equipment for oil field

A sewage sludge and ultrasonic technology, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of equipment energy consumption, high power, small sludge range, etc., to reduce equipment investment , Improve power density, shorten the effect of the process chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

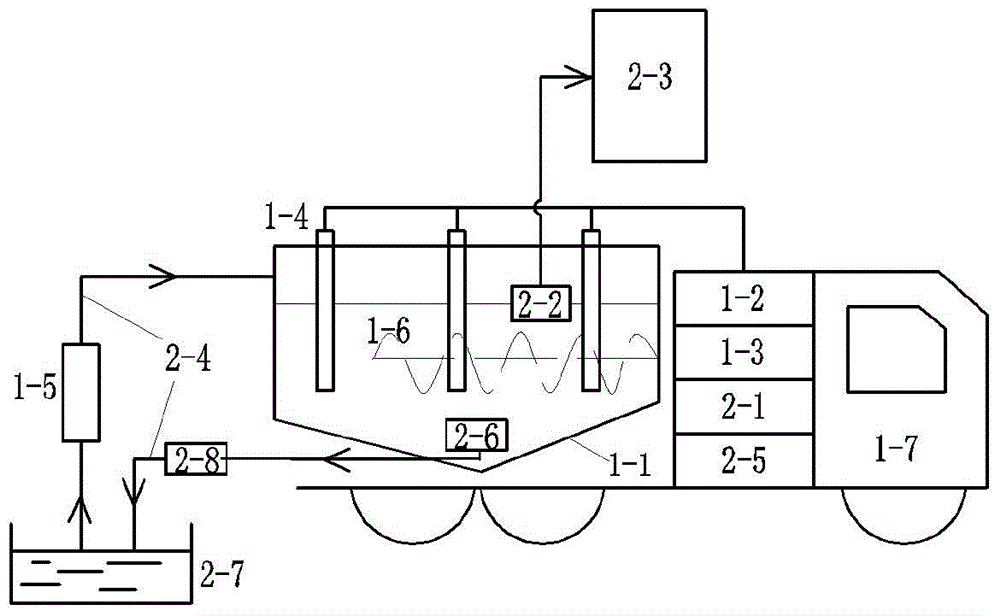

[0020] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

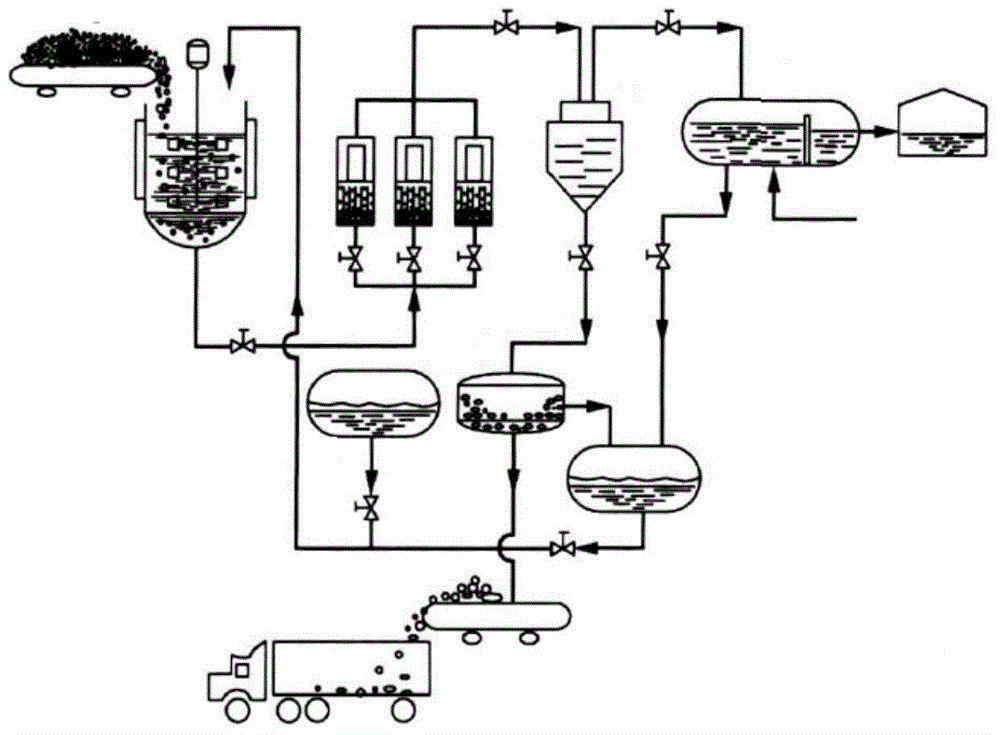

[0021] The purpose of the present invention is to propose a special ultrasonic sludge deoiling equipment for oil fields, which consists of two parts: an ultrasonic sludge separation system and an oil-water and liquid-solid separation system. The ultrasonic sludge separation system can transport the sludge to the ultrasonic In the sludge separation tank, the ultrasonic transducer fixed on the ultrasonic sludge separation tank performs ultrasonic vibration on the sludge in the ultrasonic sludge separation tank, and the sludge is vibrated by the ultrasonic transducer. Oil-water and liquid-solid separation system to separate crude oil.

[0022] Four or more transducers are superimposed on the wavele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com