A kind of transformer oil anti-gassing component and preparation method thereof

A transformer oil and anti-gassing technology, which is applied in the field of transformer oil, can solve the problems of high investment cost and large amount of addition, and achieve good adsorption effect, improved gassing performance, and low alkali nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, the preparation of anti-gassing component of transformer oil

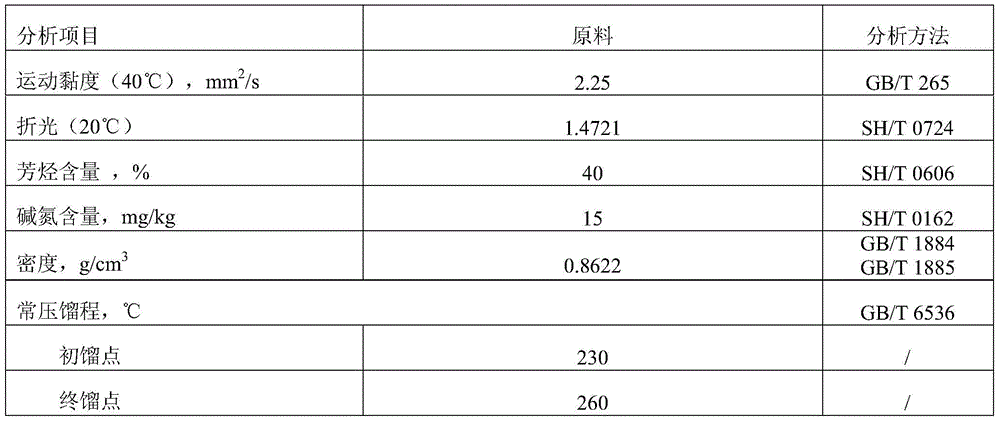

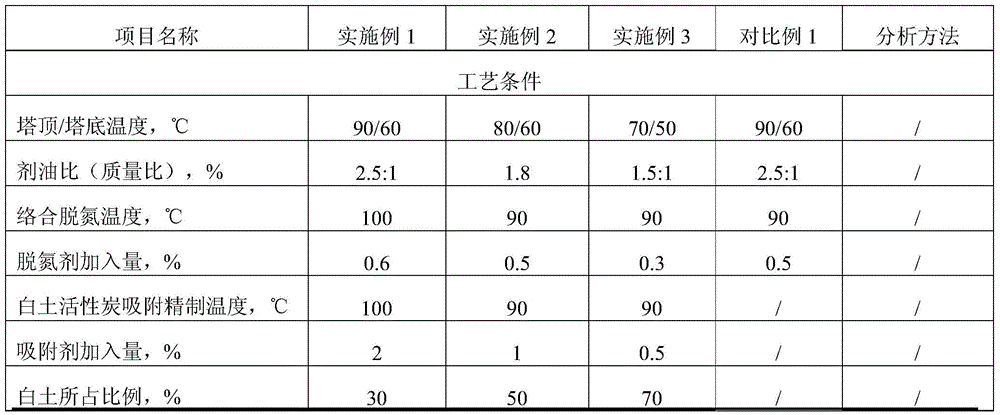

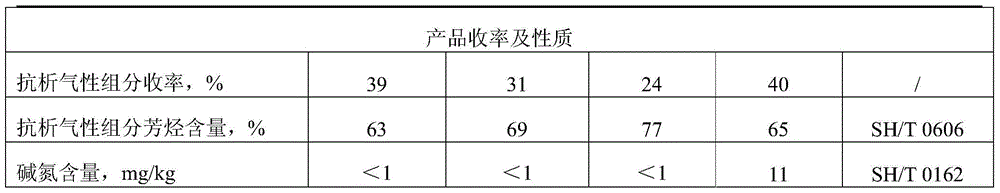

[0034] Using the 230-260°C distillate oil of Suizhong 36-1 crude oil produced by the industrial equipment of CNOOC (Qingdao) Heavy Oil Processing Engineering Technology Research Center Co., Ltd. as raw material (as shown in Table 1), furfural was refined with furfural as a solvent As shown in Table 2, the furfural refining conditions are: tower top temperature 90°C, tower bottom temperature 60°C, solvent-to-raw oil mass ratio 2.5:1, and the extracted furfural refined oil is subjected to complex denitrification-clay activated carbon combination The gassing-resistant components were obtained through the adsorption refining process. The complexation denitrification reaction temperature is 100°C, relative to the total amount of furfural refining extracted oil, the addition of denitrification agent is 0.6%, and the contact time is 30min; The furfural refining extracts the total amount of oil, the a...

Embodiment 2

[0035] Embodiment 2, preparation of transformer oil anti-gassing component

[0036] Using the 230-260°C distillate oil of Suizhong 36-1 crude oil produced by the industrial equipment of CNOOC (Qingdao) Heavy Oil Processing Engineering Technology Research Center Co., Ltd. as raw material (as shown in Table 1), furfural was refined with furfural as a solvent As shown in Table 2, the conditions for furfural refining are: tower top temperature 80°C, tower bottom temperature 60°C, mass ratio of solvent to raw oil is 1.8:1, and the extracted furfural refined oil is subjected to complex denitrification-clay activated carbon combination The gassing-resistant components were obtained through the adsorption refining process. The complex denitrification reaction temperature is 90°C, relative to the total amount of furfural refined oil extracted, the amount of denitrification agent added is 0.5%, and the contact time is 30 minutes; The total amount of the adsorbent is 1%, the clay accoun...

Embodiment 3

[0038] Example 3, Preparation of transformer oil anti-gassing component

[0039] Using the 230-260°C distillate oil of Suizhong 36-1 crude oil produced by the industrial equipment of CNOOC (Qingdao) Heavy Oil Processing Engineering Technology Research Center Co., Ltd. as raw material (as shown in Table 1), furfural was refined with furfural as a solvent As shown in Table 2, the conditions for furfural refining are: tower top temperature 70°C, tower bottom temperature 50°C, mass ratio of solvent to raw oil is 1.5:1, and the extracted furfural refined oil is subjected to complex denitrification-clay activated carbon combination The gassing-resistant components were obtained through the adsorption refining process. The complex denitrification reaction temperature is 90°C, relative to the total amount of furfural refined oil extracted, the amount of denitrification agent added is 0.3%, and the contact time is 30 minutes; The total amount of the adsorbent is 0.5%, clay accounts fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com