A Gravity Adaptive Scribing Mechanism

A self-adaptive, gravity technology, applied in biochemical instruments, biochemical equipment and methods, biological material sampling methods, etc., can solve the problems of high labor cost, high randomness of manual operation, and unstandardized operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

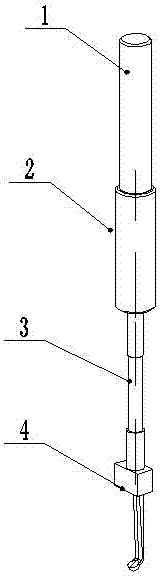

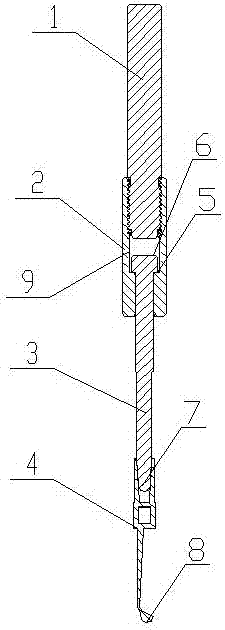

[0024] attached figure 1 It is a structural schematic diagram of the gravity self-adaptive scribing mechanism of the present invention, with figure 2 It is a schematic cross-sectional structure diagram of the gravity adaptive marking mechanism of the present invention. In the figure, 1 is a fixed end, 2 is a locking sleeve, 3 is a connecting end, 4 is a marking pen, 5 is a platform, 6 is a positioning block, and 7 is a Opening, 8 is the marking end, and 9 is the through hole. As shown in the figure, the gravity adaptive marking mechanism of the present invention includes a fixed end 1, a locking sleeve 2, a connecting end 3 and a marking line arranged from top to bottom. Pen 4, the fixed end 1 is a rigid structure, and its top is adapted to the external mechanical movement mechanism; the top of the locking sleeve 2 is a sleeve-like structure that opens upward, and is fixedly matched with the bottom of the fixed end 1, The bottom of the locking sleeve 2 is a sleeve-like struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com